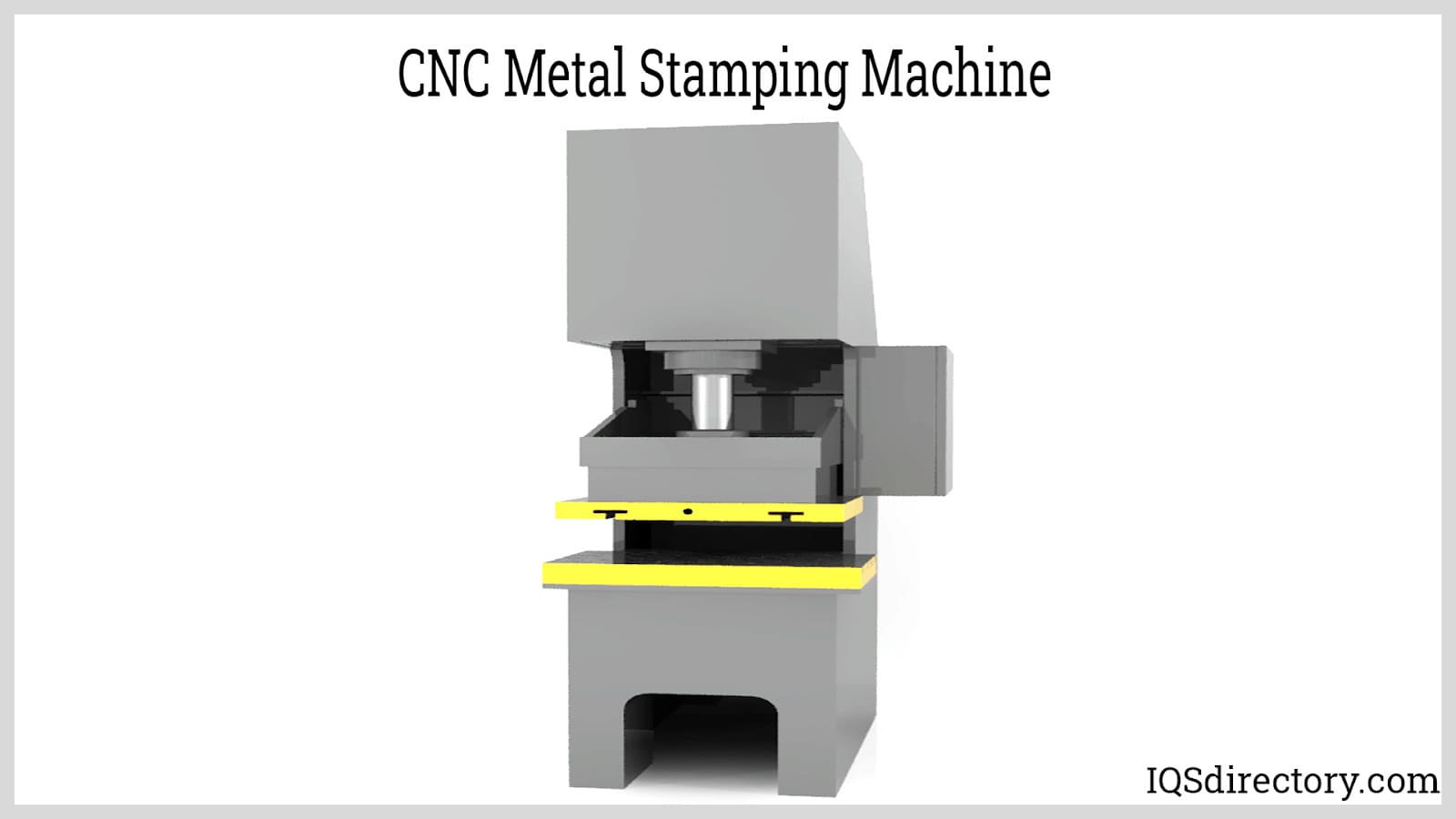

Automotive metal stamping presses offer rapid stamping as well as repeatable and programmable dimensions which in turn increases both dimensional control and standardizing accuracy. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

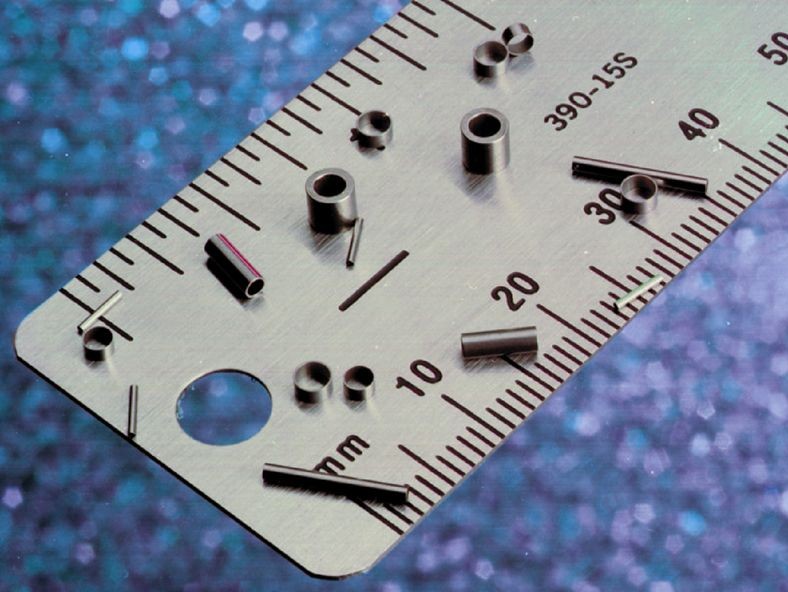

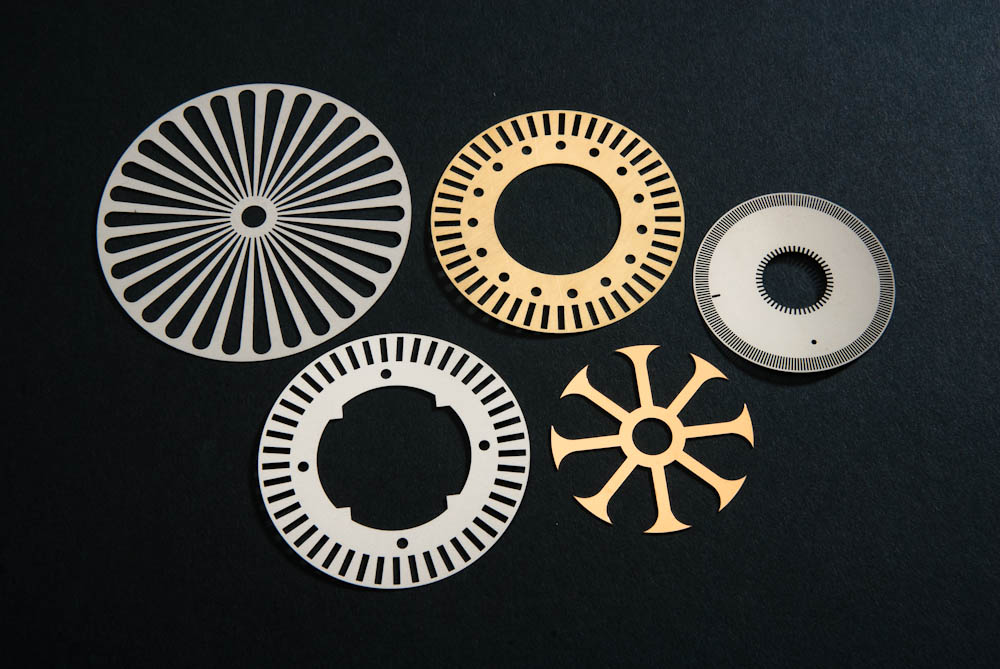

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

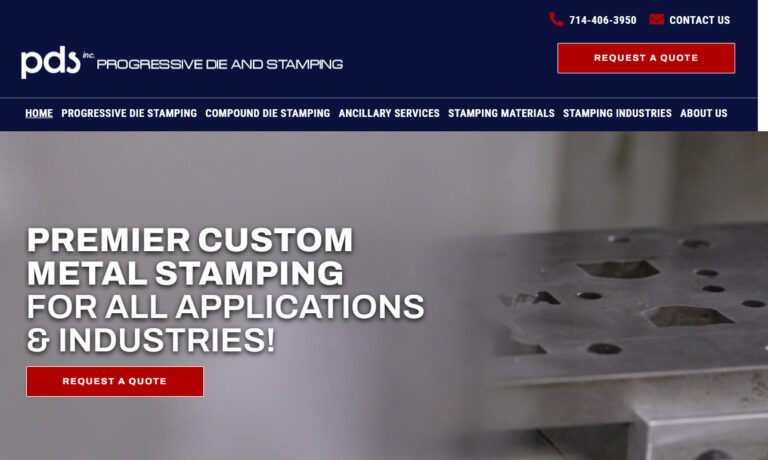

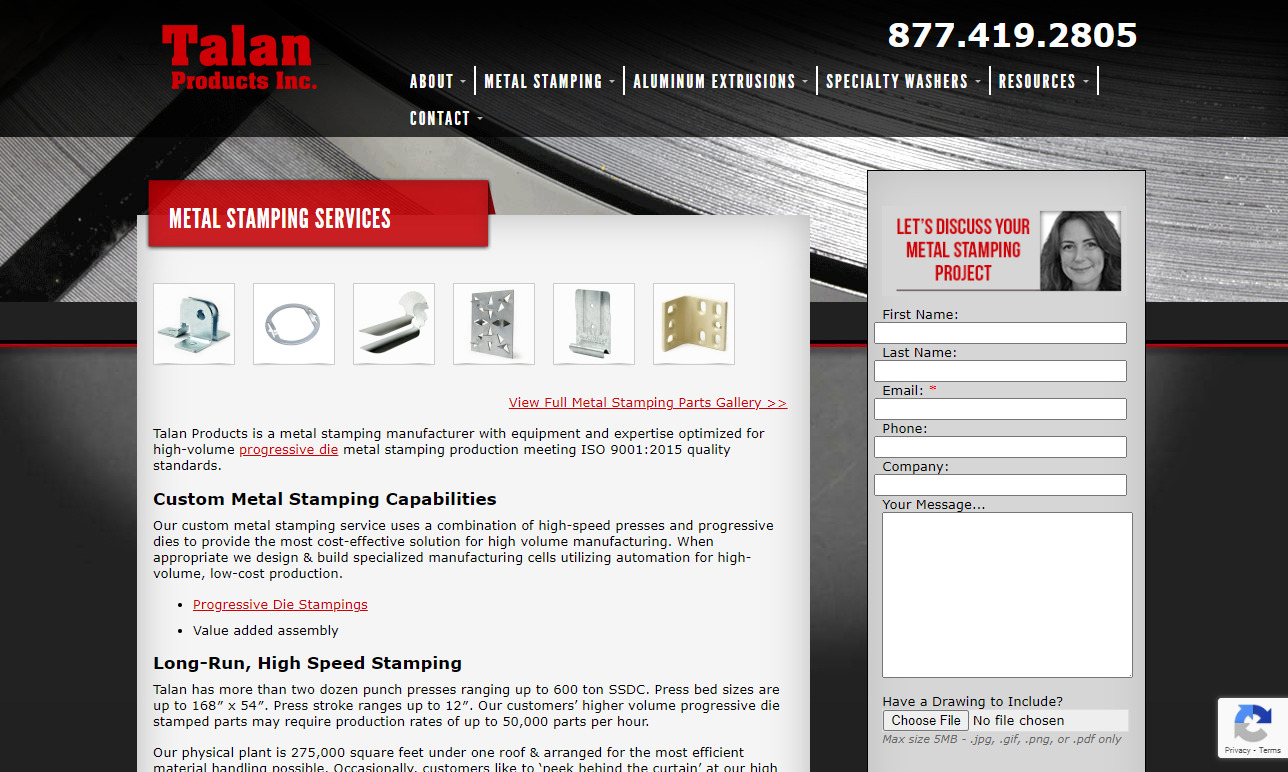

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

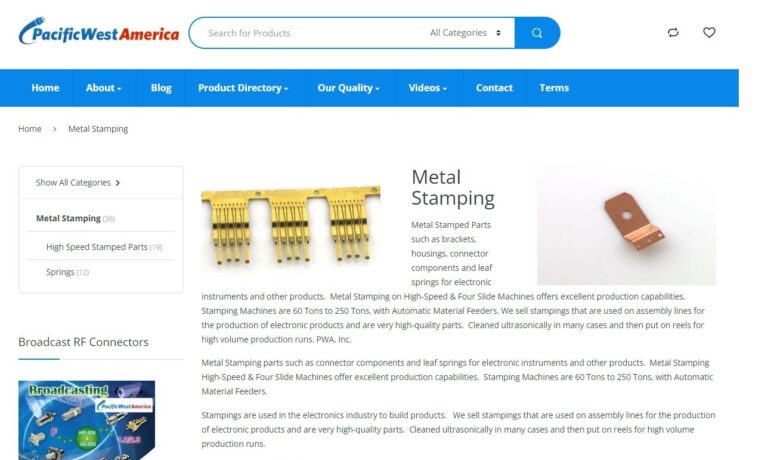

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

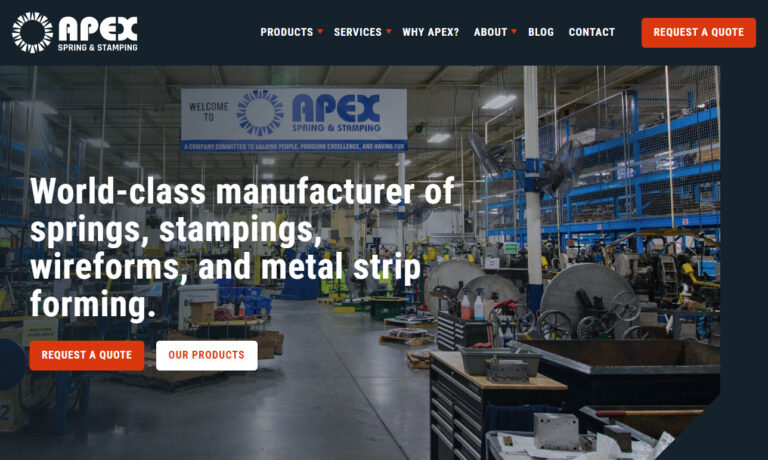

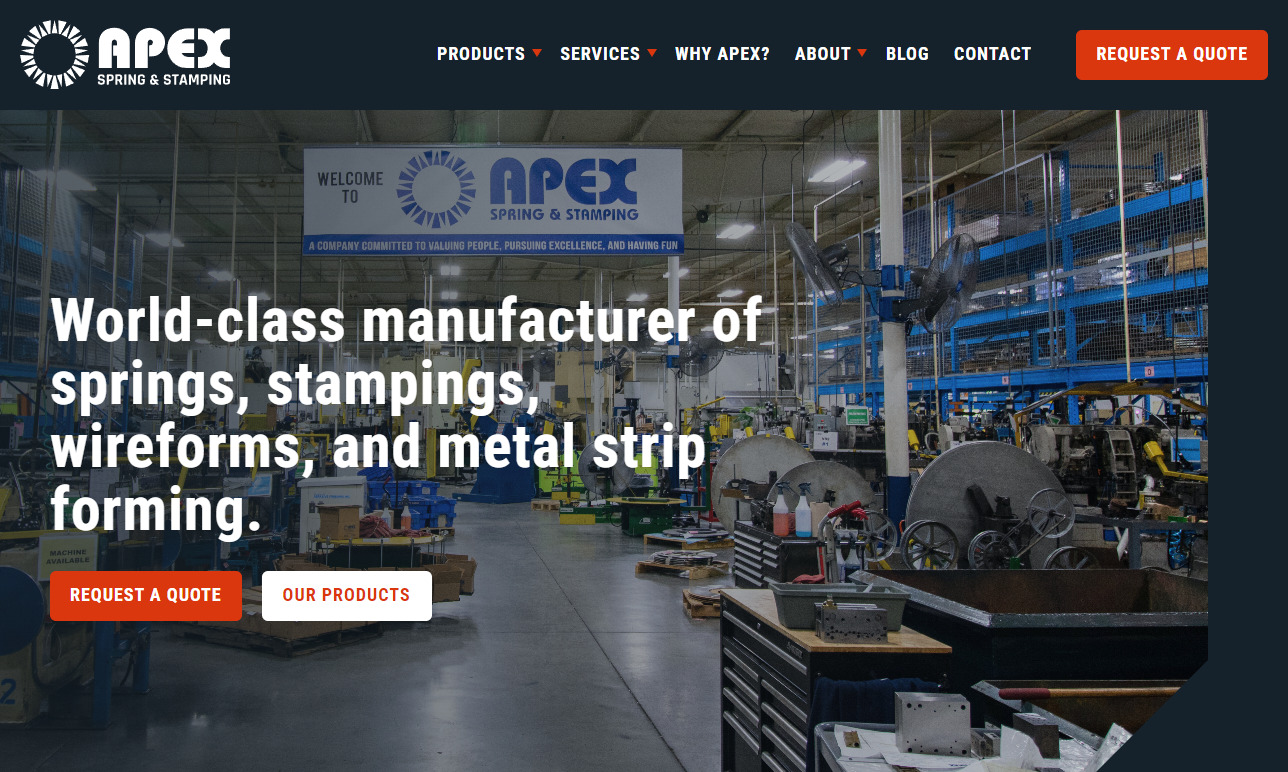

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

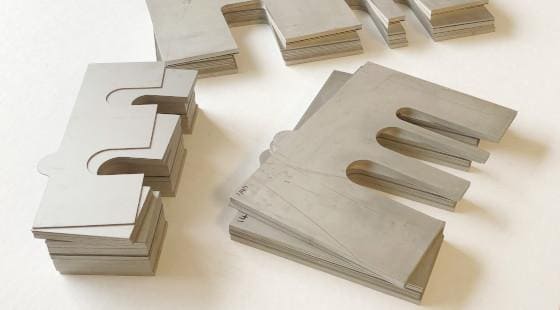

We perform medium to large quantities of precision metal stamping and commercial metal stampings. We do our tooling design in house using the latest CAD machinery. We also offer other in house services like tapping, spot welding, arc welding, and assembly of products.

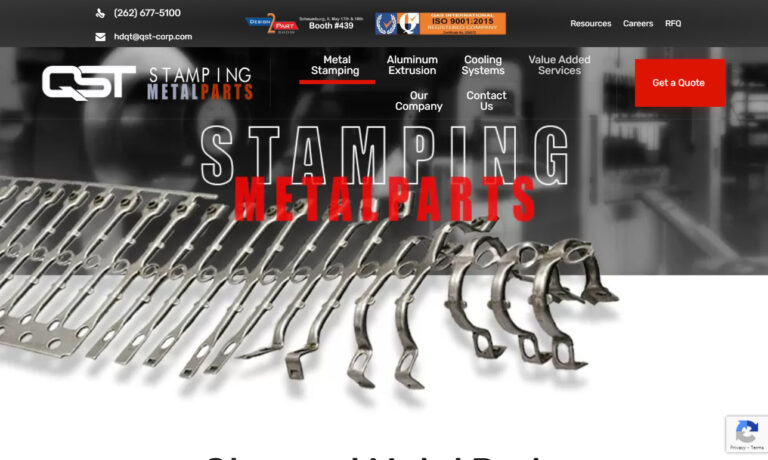

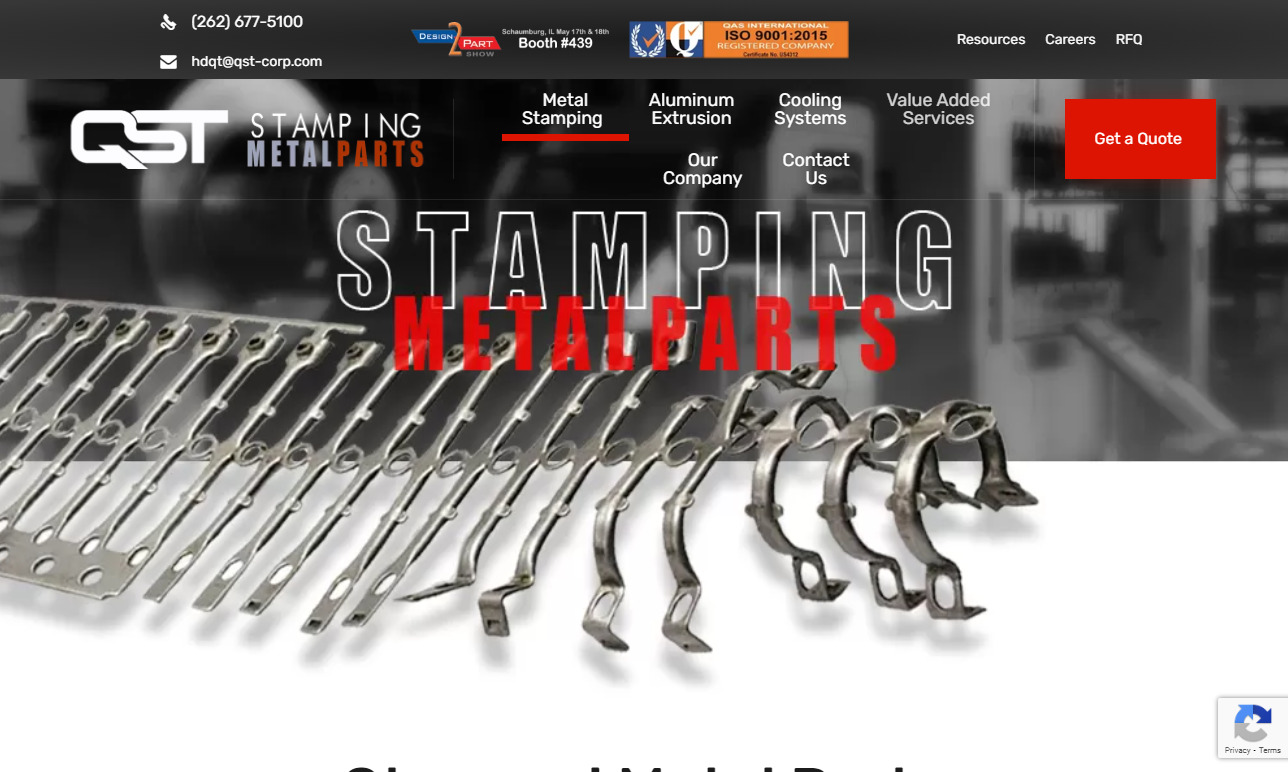

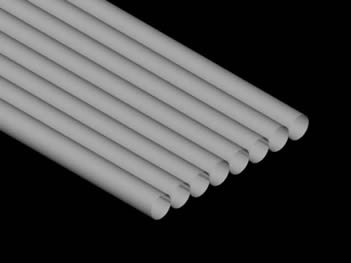

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

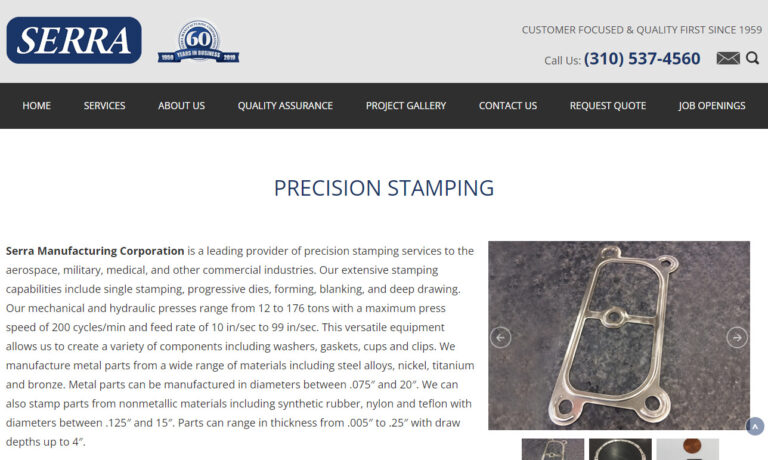

At Serra Manufacturing Corporation, we take great pride in our position as a leading manufacturer of precision-engineered metal stampings. With a relentless commitment to quality, we have established ourselves as a trusted partner in the metal stamping industry. Allow us to introduce you to our extensive product offerings, comprehensive services, and our unwavering dedication to delivering...

More Automotive Stamping Companies

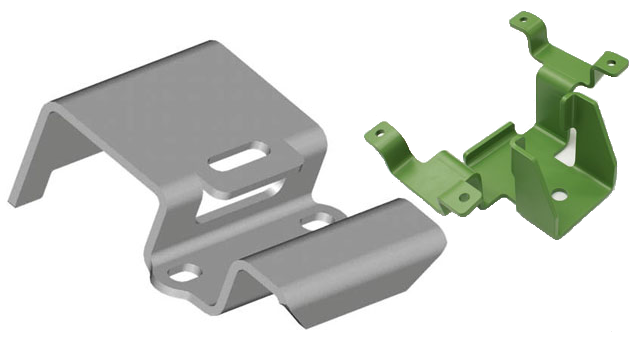

A cost-effective process, automotive stamping forms metals such as pre-coated steels, Inconel, brass, bronze, cold rolled steel, copper, stainless steel and aluminum into various automotive parts.

Automotive metal stampings is able to form a broad range of automotive parts including fenders, hub caps, trim, engine mounts, connectors, terminal leadframes, pins and oxygen sensors.

Additional auto parts include braking, fuel delivery, sunroof systems, seating, powertrain systems, fluid sealing systems, air bag cups and bayonet sockets.

Not only beneficial to the automotive industry, automotive stamping is also used in industries such as appliance, hardware, pharmaceutical, HVAC, plumbing and fire prevention.

Broaching

Broaching CNC Machining

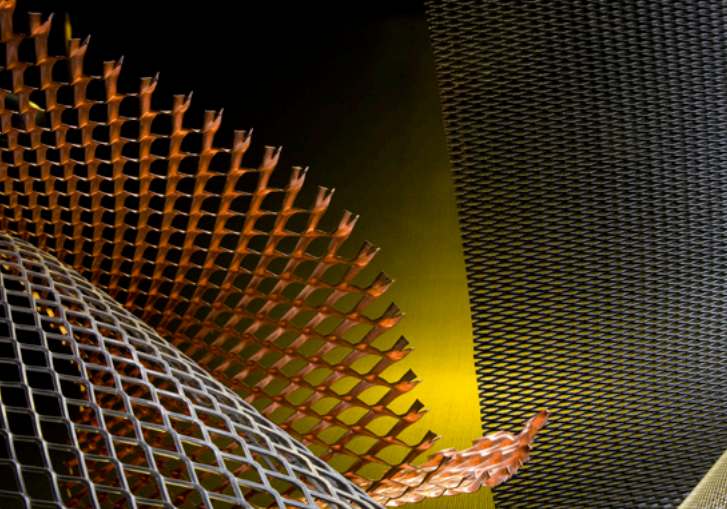

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

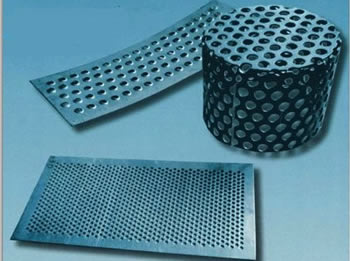

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services