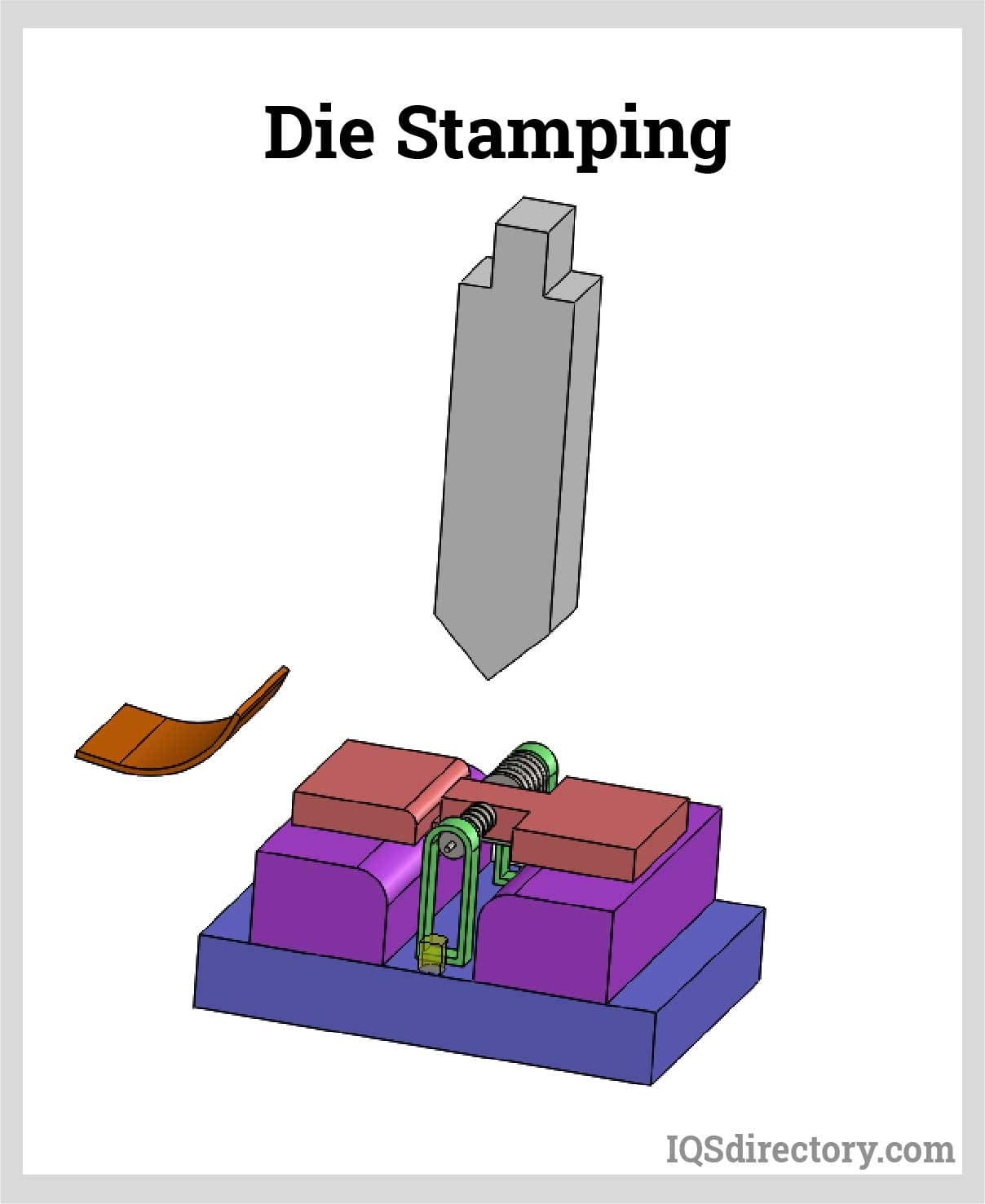

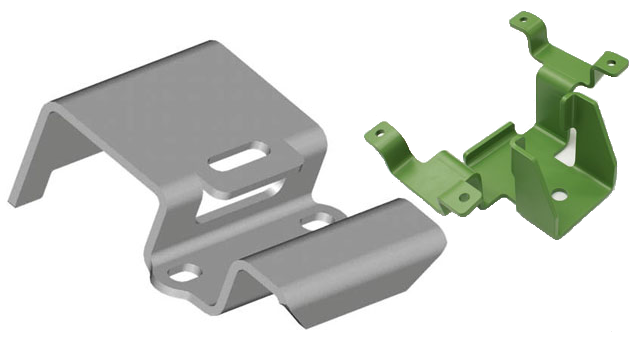

A die is a press tool for cutting or forming material in a stamping machine, and this process utilizes several dies together on the same piece of sheet metal, and as a result is capable of encompassing punching, coining, bending and many other ways of shaping blanks, or raw metal material, into various parts and components. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

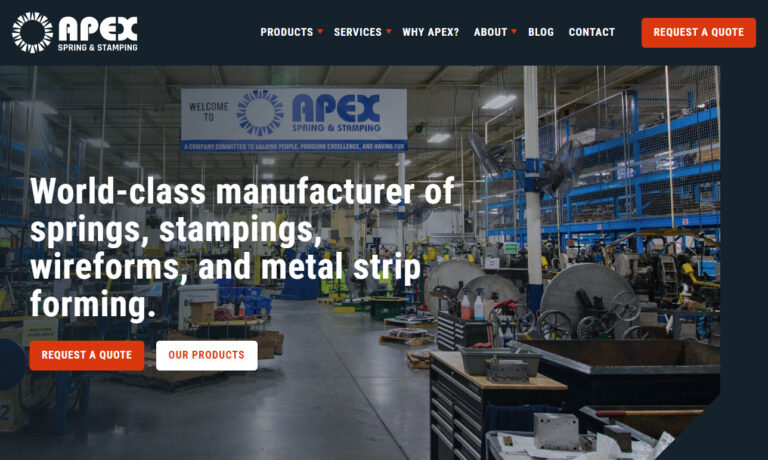

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

We perform medium to large quantities of precision metal stamping and commercial metal stampings. We do our tooling design in house using the latest CAD machinery. We also offer other in house services like tapping, spot welding, arc welding, and assembly of products.

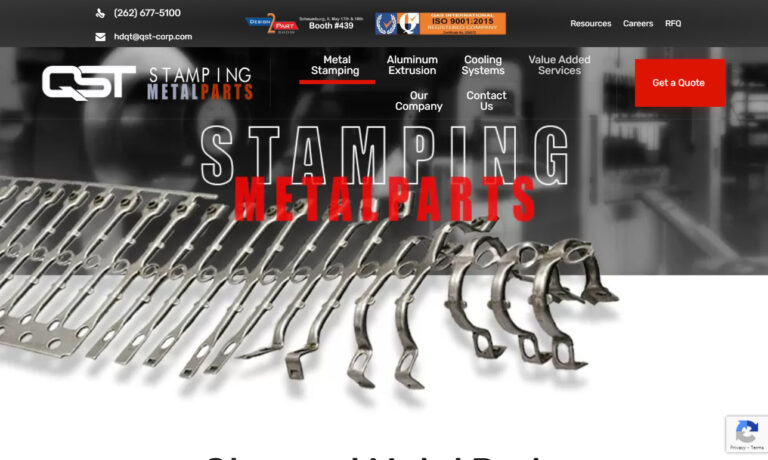

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

At Serra Manufacturing Corporation, we take great pride in our position as a leading manufacturer of precision-engineered metal stampings. With a relentless commitment to quality, we have established ourselves as a trusted partner in the metal stamping industry. Allow us to introduce you to our extensive product offerings, comprehensive services, and our unwavering dedication to delivering...

More Progressive Stamping Companies

Since multiple dies stamp the sheet metal at the same time, progressive die stamping is able to combine forming and cutting processes for efficiency and economy.

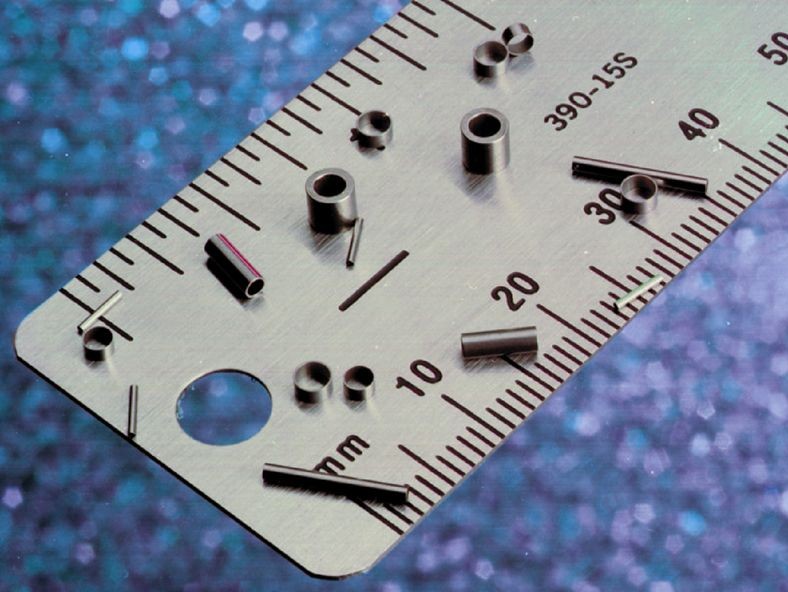

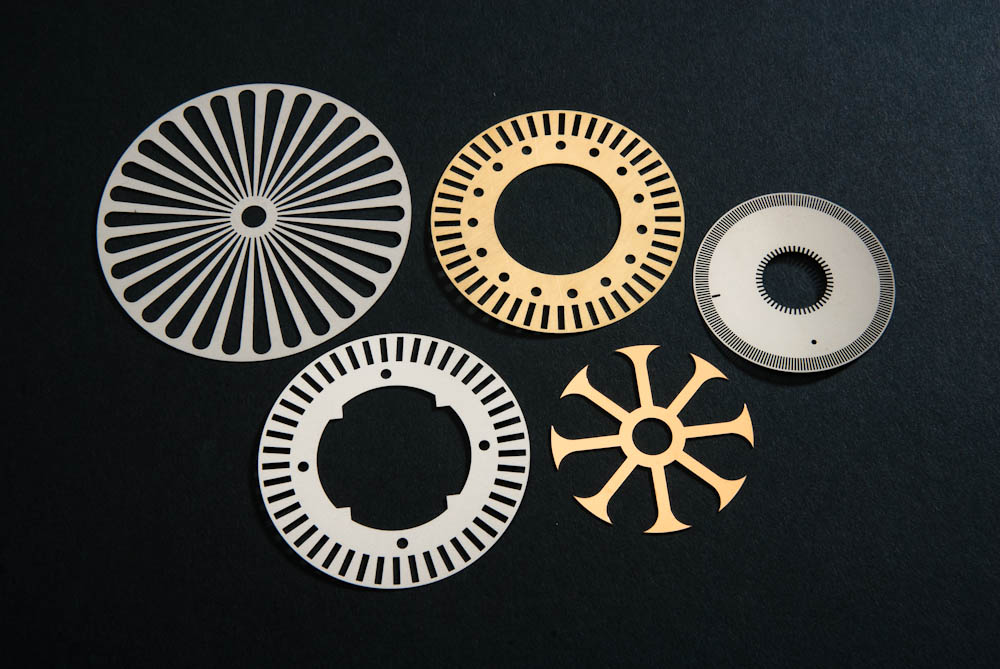

This metal stamping process is used to form small metal components quickly, and as a result is used in many applications requiring high-precision.

Some examples of applications and industries that progressive stampings are utilized in include: medical, for critical components such as surgical instrumentation and dental grinding disks; industrial manufacturing, for use in the production of tools and automation equipment components; food and beverage, utilized in various forms of packaging such as lids for pop cans; and automotive, in which they are used as braking systems, fuel delivery systems and bayonet sockets.

There is a wide range of materials that can be formed using the progressive die stamping process, which includes: most aluminum alloys, brass, cold rolled steel, copper, zinc, stainless steel, titanium and galvanized steel.

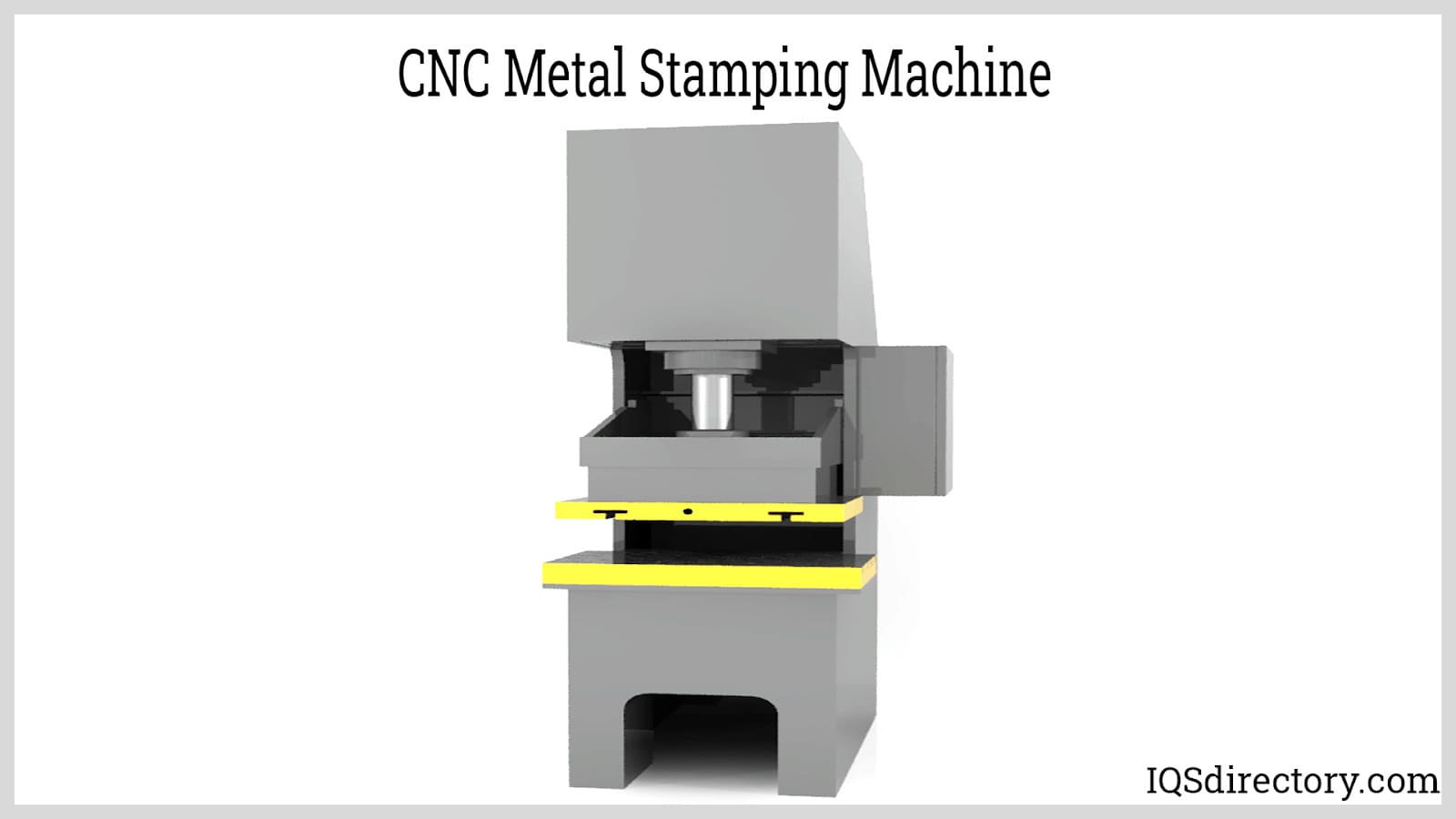

To begin the progressive die stamping process, first strips of metal are pushed by a feeding system through a series of progressive stamping die stations. The dies in these stations are housed within a reciprocal stamping press, typically hydraulically-powered.

The reciprocal stamping press stamps the material by the process of the press moving up and the top die moving with it so that when the press moves back down so does the die, which results in the stamping of the material. Additional work is performed at each station that the material is brought through. Although the cost of the multiple dies that are used in progressive die stamping are expensive, they usually last for the life of the project.

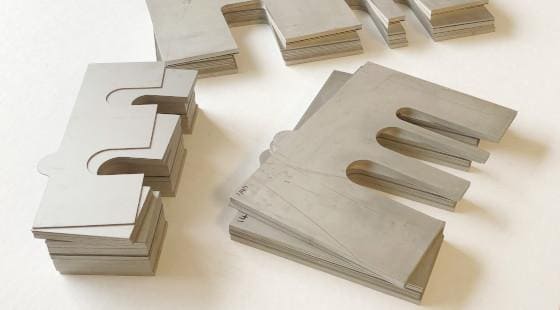

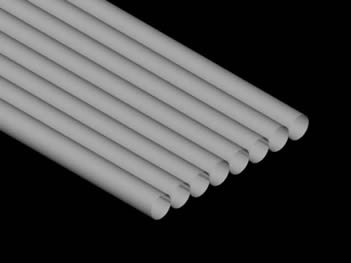

Manufactured from tool steel, the dies offer many advantageous characteristics such as high abrasive force resistance, high shock load resistance and the ability to retain a sharp cutting edge. Thus, despite the initial cost, the final price per piece is exceptionally low.

Broaching

Broaching CNC Machining

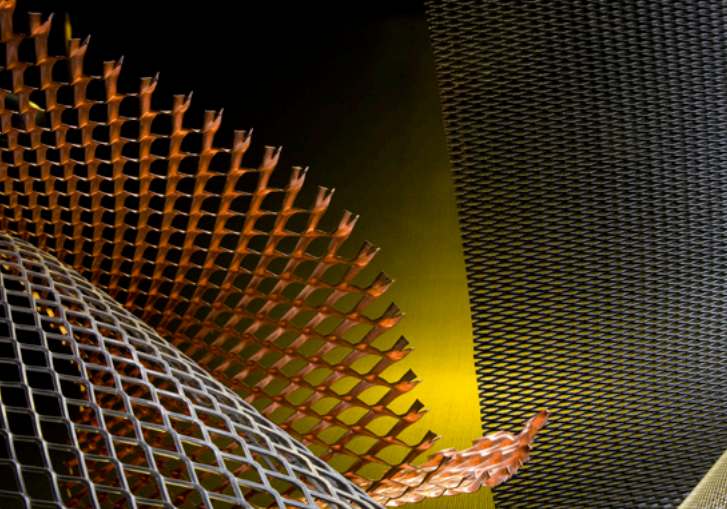

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

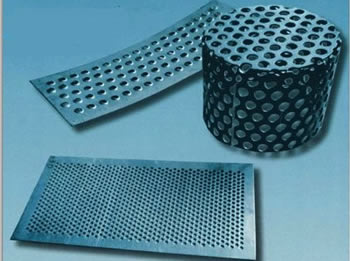

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services