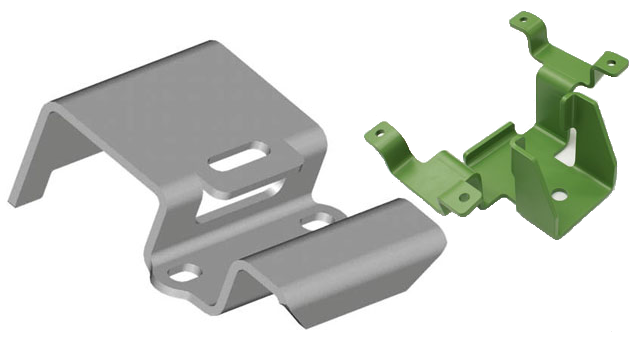

Aluminum stampings are components made from thin sheets of aluminum that are formed into a specific shape using a stamping process, deep drawing, or hydroforming. These components are lightweight, durable, and versatile, making them popular in various industries. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

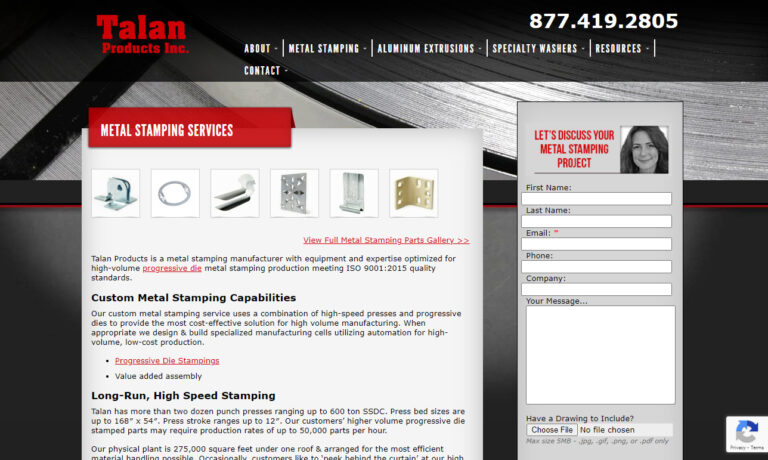

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

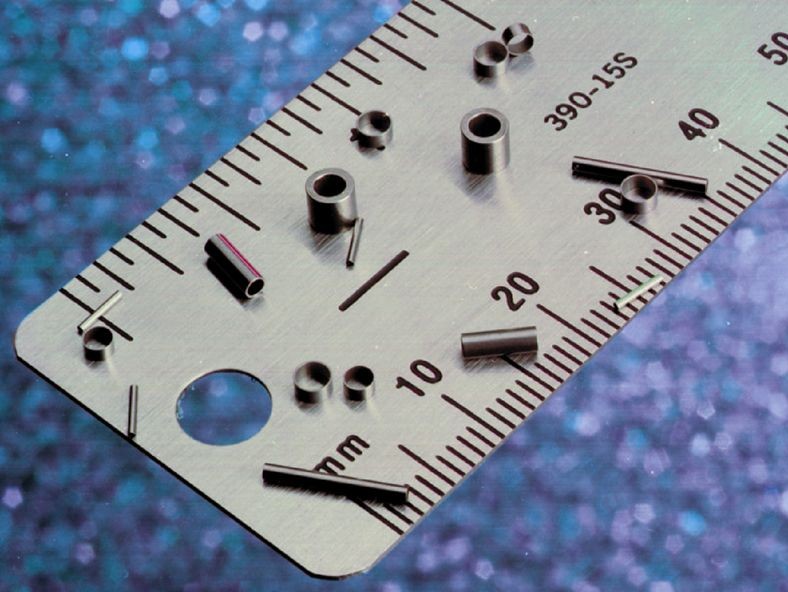

As a precision stamping specialist, we take pride in producing high quality custom metal stampings for our customers. We are experts in progressive and compound die stamping. Our capabilities allow us to manufacture parts from coil or strip material up to 6 inches wide and work with a range of thicknesses from .001 to .134 inches. Find out more on our website, or give us a call today!

At Cygnet Stamping & Fabricating, Inc., we specialize in providing comprehensive solutions for metal stampings tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of metal fabrication, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio...

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

Lyons has specialized in precision metal stamping and contract manufacturing for over 65 years. As an AS9100, ISO 9001:2015 and ISO 13485:2016 certified company, you can count on quality first. Whether it’s a precision metal stamping requirement, a complex CNC machined part, an immediate rapid prototyping need or an intricate assembly, Lyons has the country’s top resources to help meet your...

More Aluminum Stamping Companies

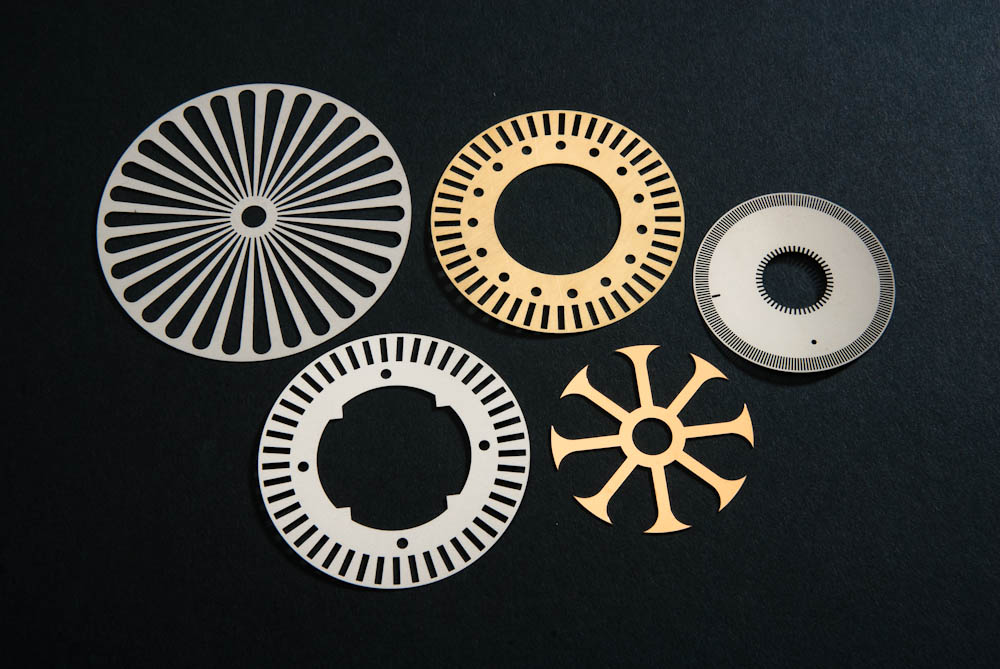

Manufacturing Processes for Aluminum Stampings

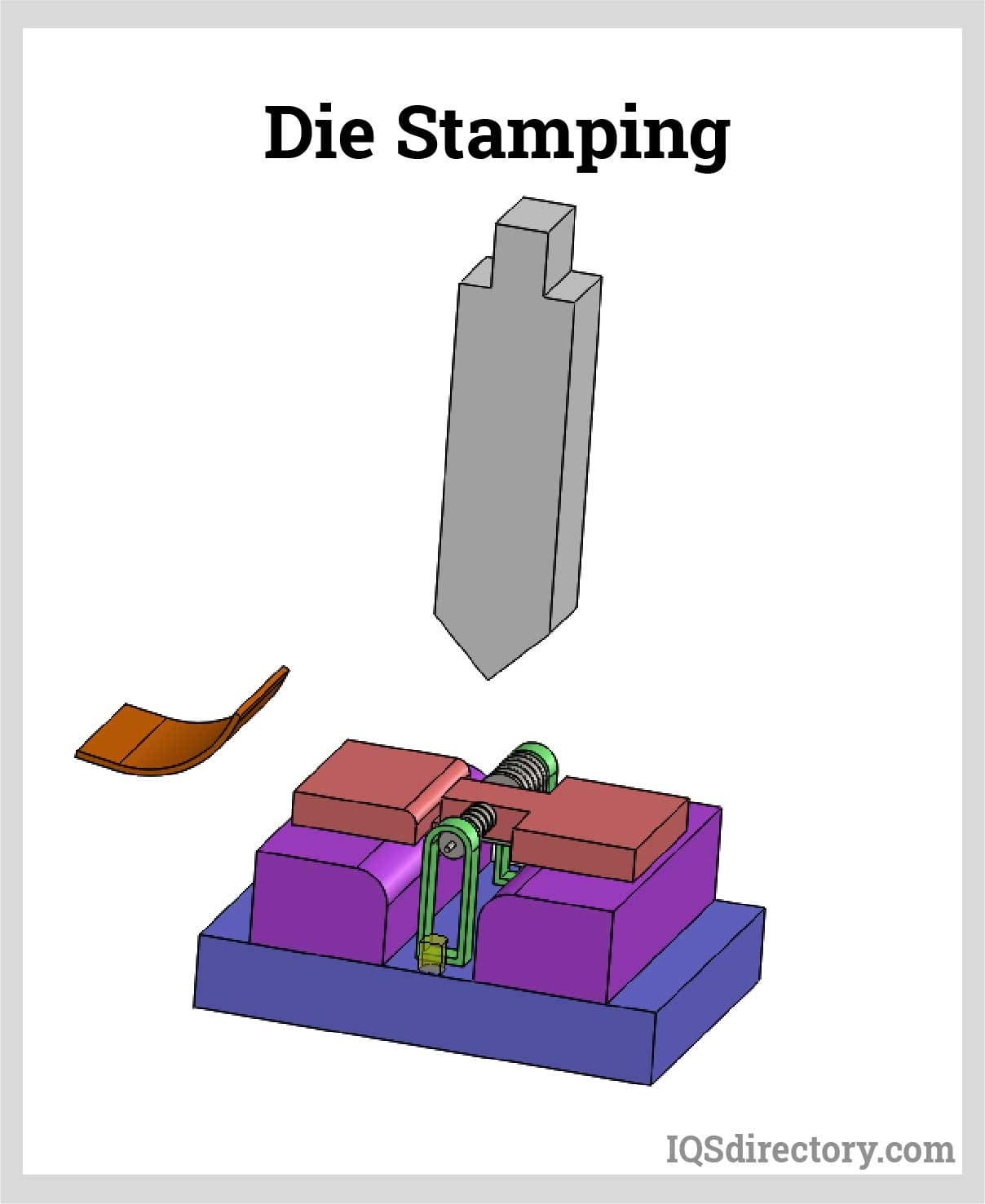

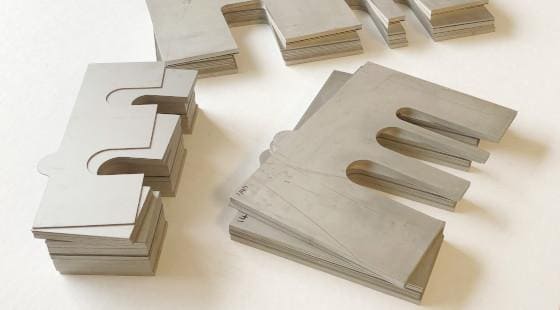

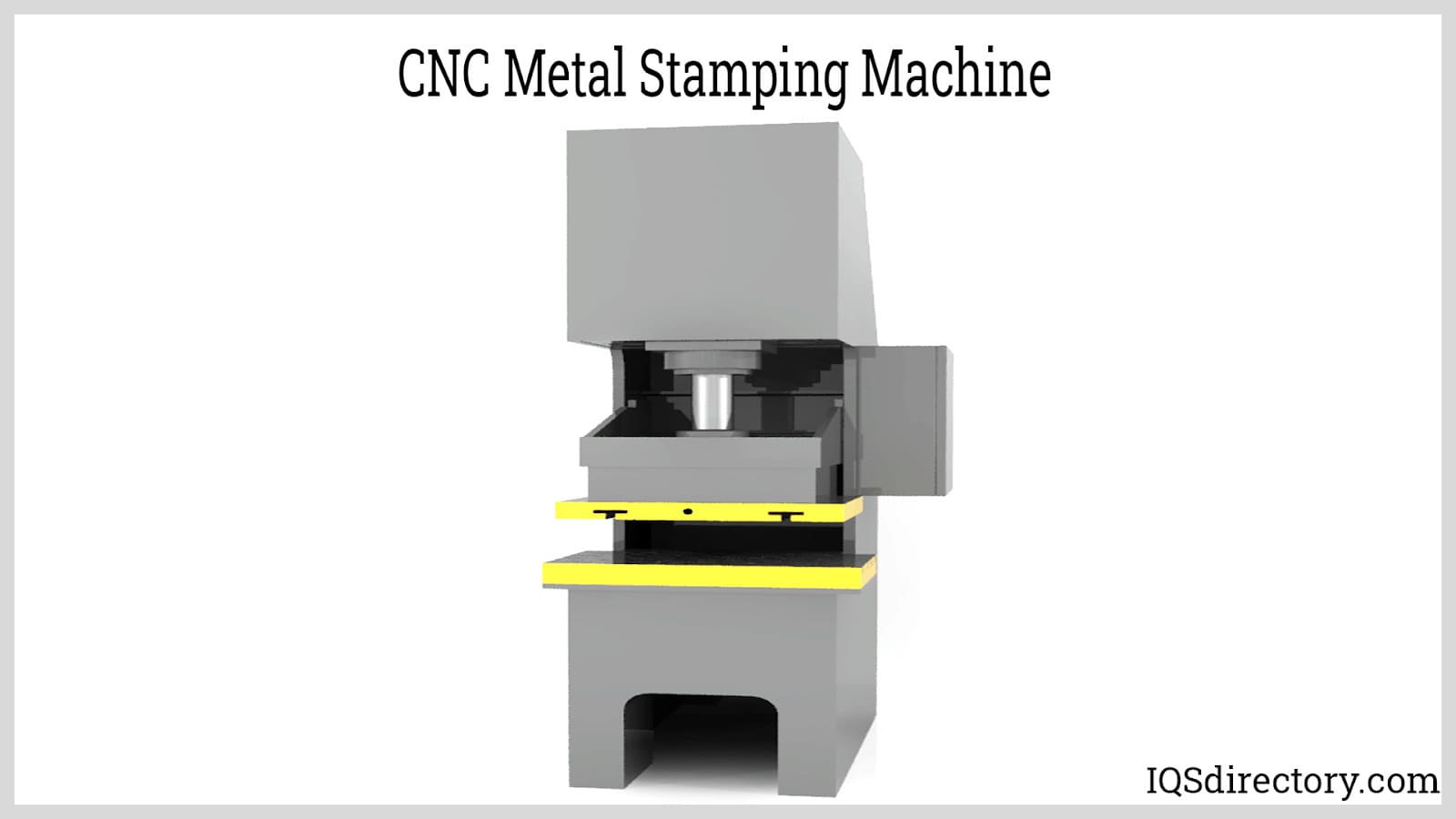

As discussed, there are different processes used to create aluminum stampings such as stamping, deep drawing, and hydroforming. Stamping involves the use of a press to stamp the aluminum sheet into a desired shape. Deep drawing, on the other hand, involves the use of a punch and die to create a deep-drawn part. Hydroforming, meanwhile, involves using a high-pressure fluid to shape the aluminum into a desired shape. Each process has its specific applications. For instance, stamping is ideal for high-volume production while deep drawing is suitable for making complex shapes with a uniform wall thickness.

Considerations Regarding Aluminum Stampings

One of the concerns with aluminum stampings is material fatigue, which can cause failure over time. To address this concern, manufacturers use quality control measures and improved production processes to ensure that the stamped parts are durable and long-lasting. Another concern is surface imperfections, which can affect the appearance and performance of the part. Manufacturers use various techniques such as deburring and polishing to remove any imperfections and improve the part's finish.

Legal and Manufacturer Efforts for Aluminum Stampings

In the United States, there are several laws and regulations governing the creation and use of aluminum stampings. The Occupational Safety and Health Administration (OSHA) sets guidelines for the handling of aluminum and other metals to ensure worker safety. The Environmental Protection Agency (EPA) regulates the disposal of hazardous waste generated during the production of aluminum stampings to ensure that it does not harm the environment.

In addition to these general regulations, there are also specific regulations that apply to different industries that use aluminum stampings. For example, the automotive industry must comply with safety standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) for vehicle emissions.

Manufacturers of aluminum stampings also have their own quality control measures in place to ensure that their products meet industry standards and customer requirements. This includes using the right type of aluminum alloy, maintaining a controlled manufacturing process, and conducting thorough testing to ensure that the stamped parts meet the required specifications.

Overall, the regulatory environment surrounding the creation and use of aluminum stampings in the United States is designed to ensure worker safety, protect the environment, and ensure that the parts meet the required industry standards.

Benefits of Aluminum Stampings

Aluminum stampings offer several benefits, such as being lightweight, durable, and versatile. Aluminum is lightweight, making it an ideal material for applications where weight reduction is important, such as in the automotive and aerospace industries. Aluminum is also durable and corrosion-resistant, making it suitable for applications in harsh environments. Additionally, aluminum stampings are versatile, and can be used in a wide range of applications across various industries.

Applications of Aluminum Stampings

As a result of these benefits, aluminum stampings are used in various industries such as:

Automotive Industry

Aluminum stampings are widely used in the automotive industry for various applications. For example, they can be used to make body panels, hoods, doors, and structural components.

Aerospace Industry

Aluminum stampings are used extensively in the aerospace industry for making parts such as structural components, aircraft skin panels, and interior fittings.

Construction Industry

Aluminum stampings are used in the construction industry for various applications. For example, they can be used to make window frames, door frames, roofing panels, and structural components.

Electronics Industry

Aluminum stampings are used in various electronic devices such as smartphones, laptops, and cameras. These stampings can be used for making frames, covers, and heat sinks, among other components.

Medical Industry

Aluminum stampings are used in medical devices such as surgical instruments, medical equipment, and diagnostic tools. These stampings can be used for making parts that require high precision and accuracy.

Energy Industry

Aluminum stampings are used in the energy industry for making parts such as heat exchangers, solar panels, and wind turbine components. These stampings are preferred for their lightweight and durable nature, which makes them suitable for use in harsh environments.

Marine Industry

Aluminum stampings are used in the marine industry for making parts such as hulls, decks, and superstructures of boats and ships. These stampings are preferred for their corrosion-resistant nature, which makes them suitable for use in saltwater environments.

Packaging Industry

Aluminum stampings are used in the packaging industry for making containers, cans, and closures. These stampings are preferred for their ability to preserve the freshness and quality of food and beverages while being lightweight and recyclable.

Choosing the Right Aluminum Stampings Manufacturer

To ensure you have the most positive outcome when purchasing aluminum stampings from an aluminum stampings manufacturer, it is important to compare several companies using our directory of aluminum stampings manufacturers, Each aluminum stampings manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each aluminum stampings business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple aluminum stampings companies with the same form.

Broaching

Broaching CNC Machining

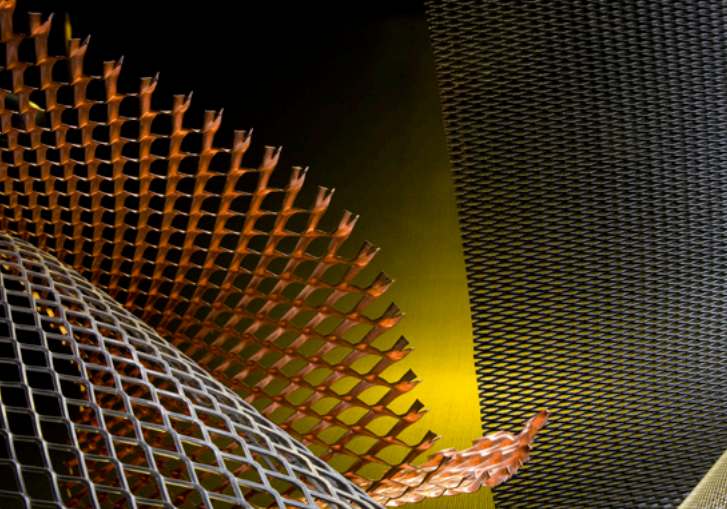

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

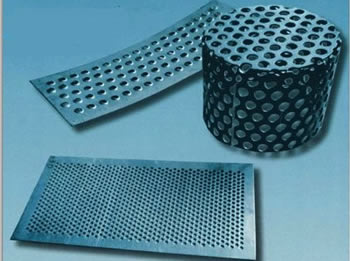

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services