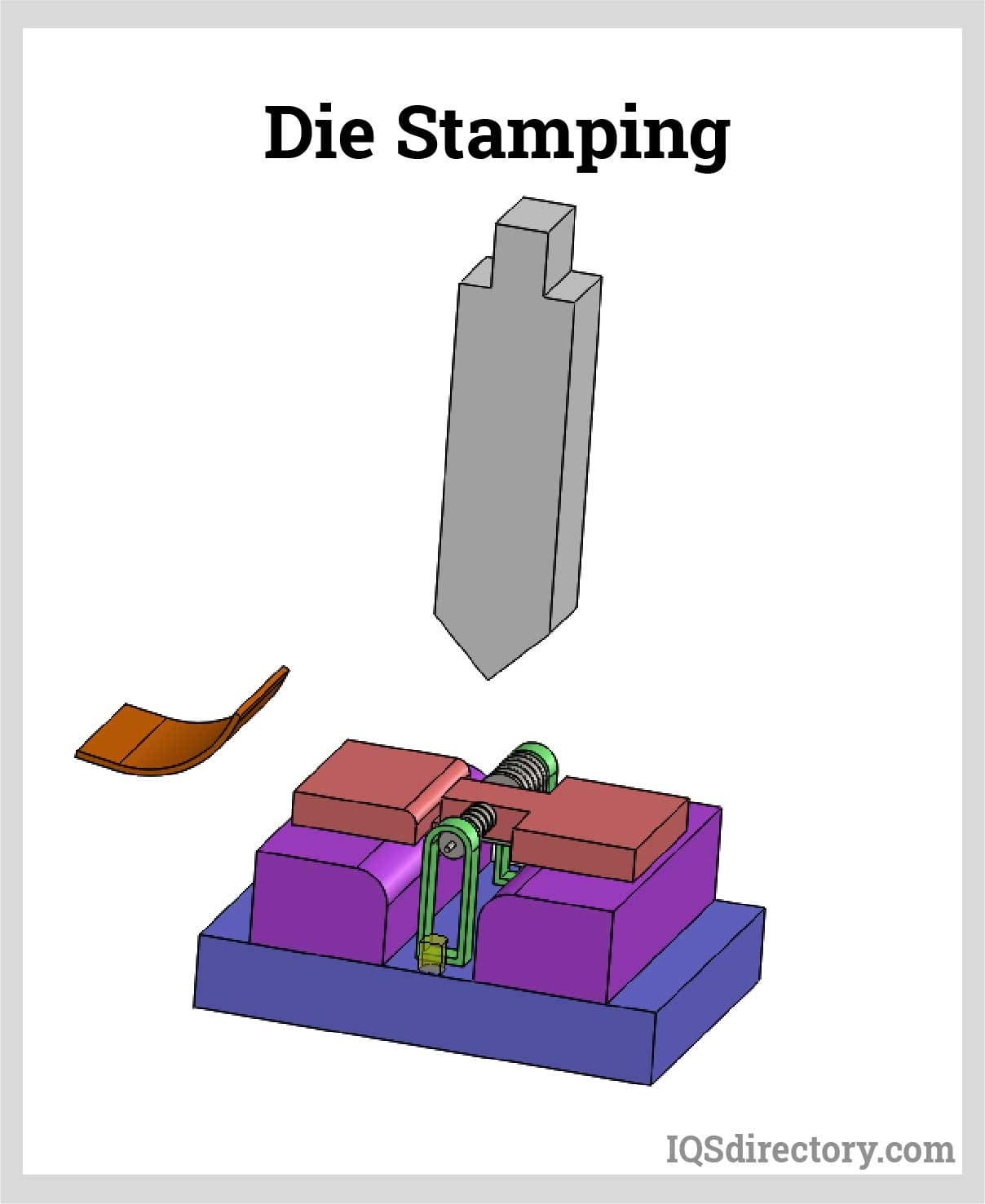

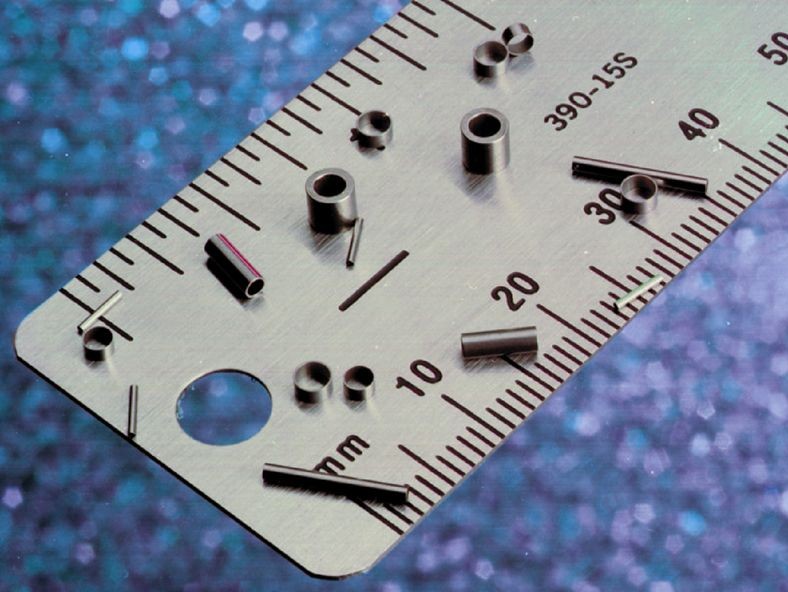

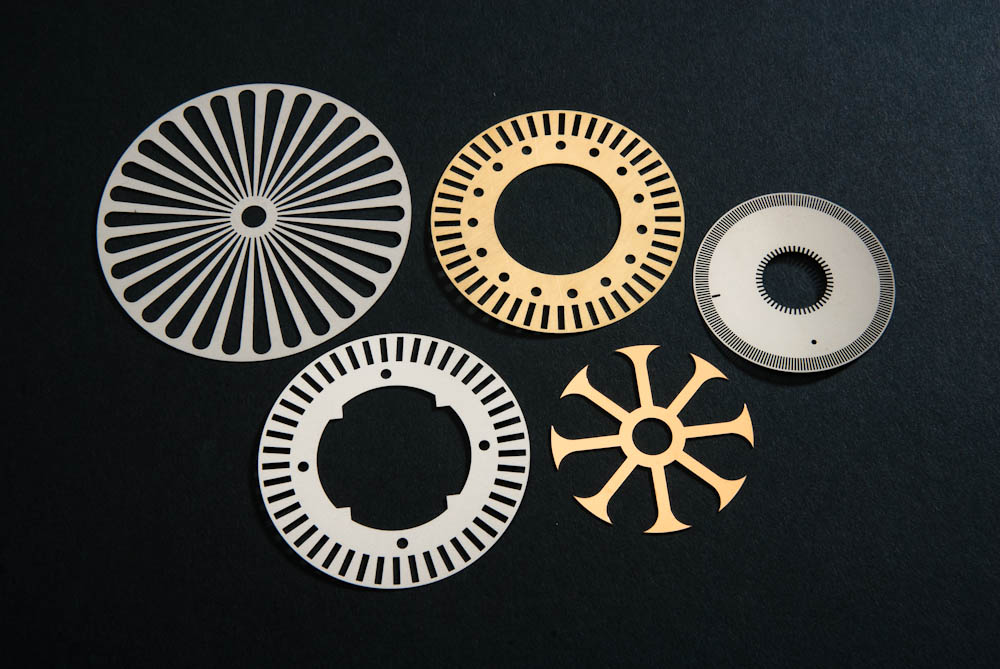

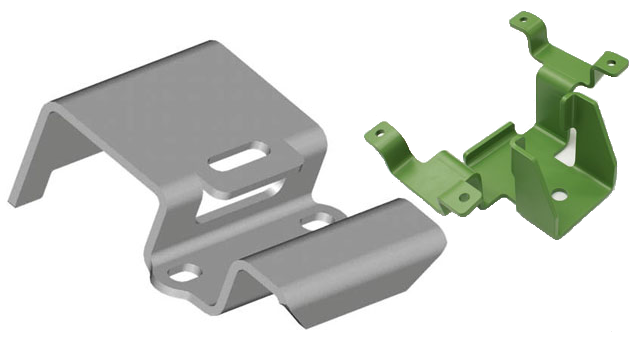

During the cold-forming procedure known as die stamping, a strip of metal often referred to as a blank or tool steel, is cut and formed using one or more dies to obtain the desired shape or profile. The workpiece can be bent or shaped into complex shapes thanks to the tension created by force employed to change and alter the geometry of the blank. As a result, the manufactured parts can be either microscopic or incredibly big, depending on the application. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

As a precision stamping specialist, we take pride in producing high quality custom metal stampings for our customers. We are experts in progressive and compound die stamping. Our capabilities allow us to manufacture parts from coil or strip material up to 6 inches wide and work with a range of thicknesses from .001 to .134 inches. Find out more on our website, or give us a call today!

At Cygnet Stamping & Fabricating, Inc., we specialize in providing comprehensive solutions for metal stampings tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of metal fabrication, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio...

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

Lyons has specialized in precision metal stamping and contract manufacturing for over 65 years. As an AS9100, ISO 9001:2015 and ISO 13485:2016 certified company, you can count on quality first. Whether it’s a precision metal stamping requirement, a complex CNC machined part, an immediate rapid prototyping need or an intricate assembly, Lyons has the country’s top resources to help meet your...

More Die Stamping Companies

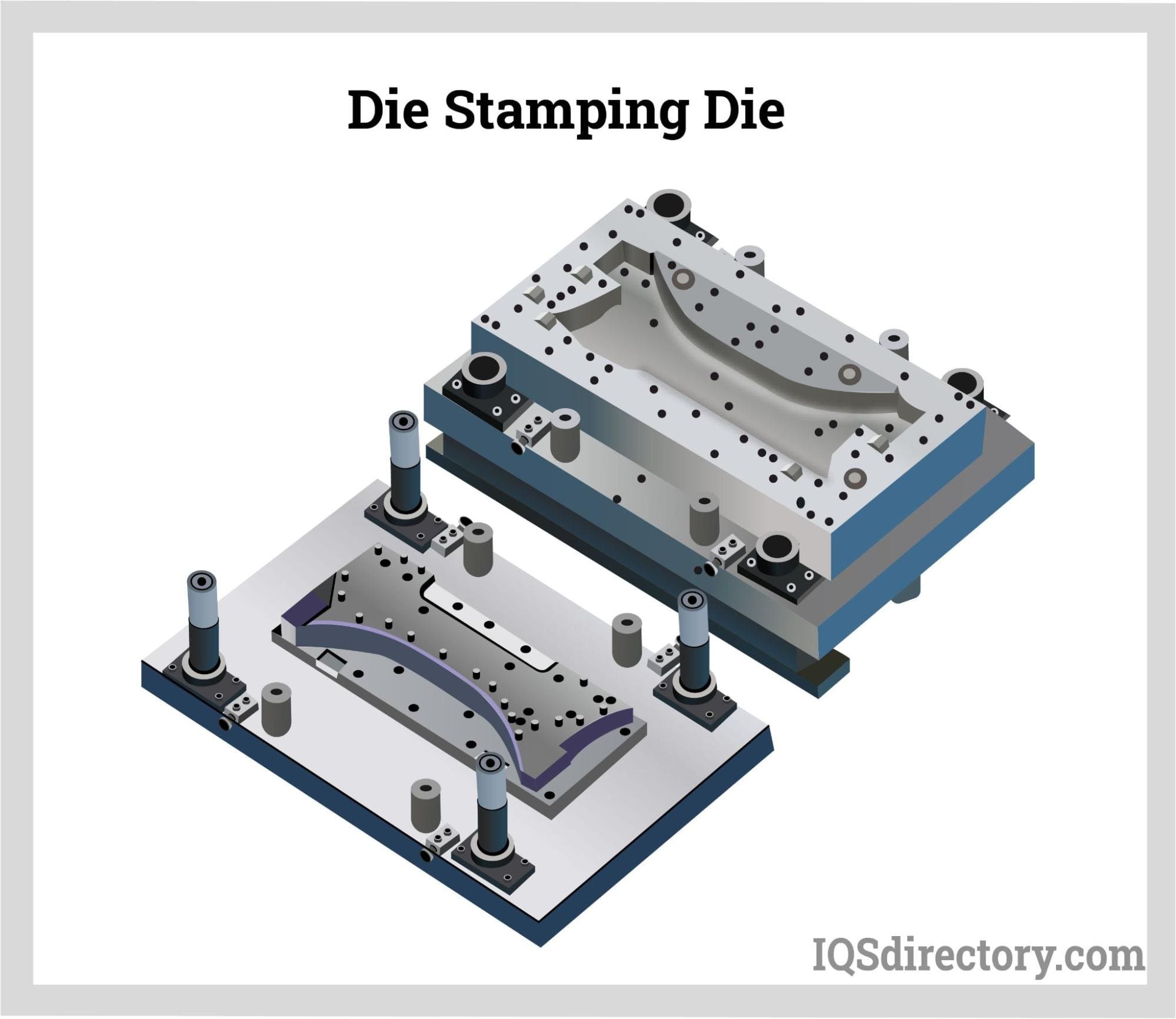

The die stamping process, also known as pressing, includes several processes, such as punching, blanking, piercing, coining, and others. Die stamping manufacturers follow detailed designs to guarantee that every punch produces the finest possible result.

Die stamping is a process that uses specialized tools called dies to create designs, which can range from simple everyday items to complex computer components. To do a single task or a series of tasks that happen one after the other, dies can be built per die stamping suppliers’ specific requests.

For die-stamping, there are three common manufacturing processes.

- Line: A single-step procedure

- Transfer: Stamping completes multiple tasks in a single cycle

- Progressive: The most typical and extensively employed

Die Stamping Operations

Cutting or shaping are the tasks that stamping dies can undertake; certain dies can combine these tasks. Every operation that die stamping producers undertake has the goal of causing separation or plasticizing so that it can take the shape of plastic.

Forming dies are:

- Bending

- Flanging

- Drawing

- Stretching

- Coining

- Ironing

Cutting dies are:

- Shearing

- Blanking

- Trimming

- Notching

- Piercing

A description of forming dies is provided below: Like a stencil, forming dies compress metals into precise forms.

Bending

A bend produces shapes resembling an L, U, or V. It is a plasticizing deformation that places stress along a single axis at the yield level below tensile strength.

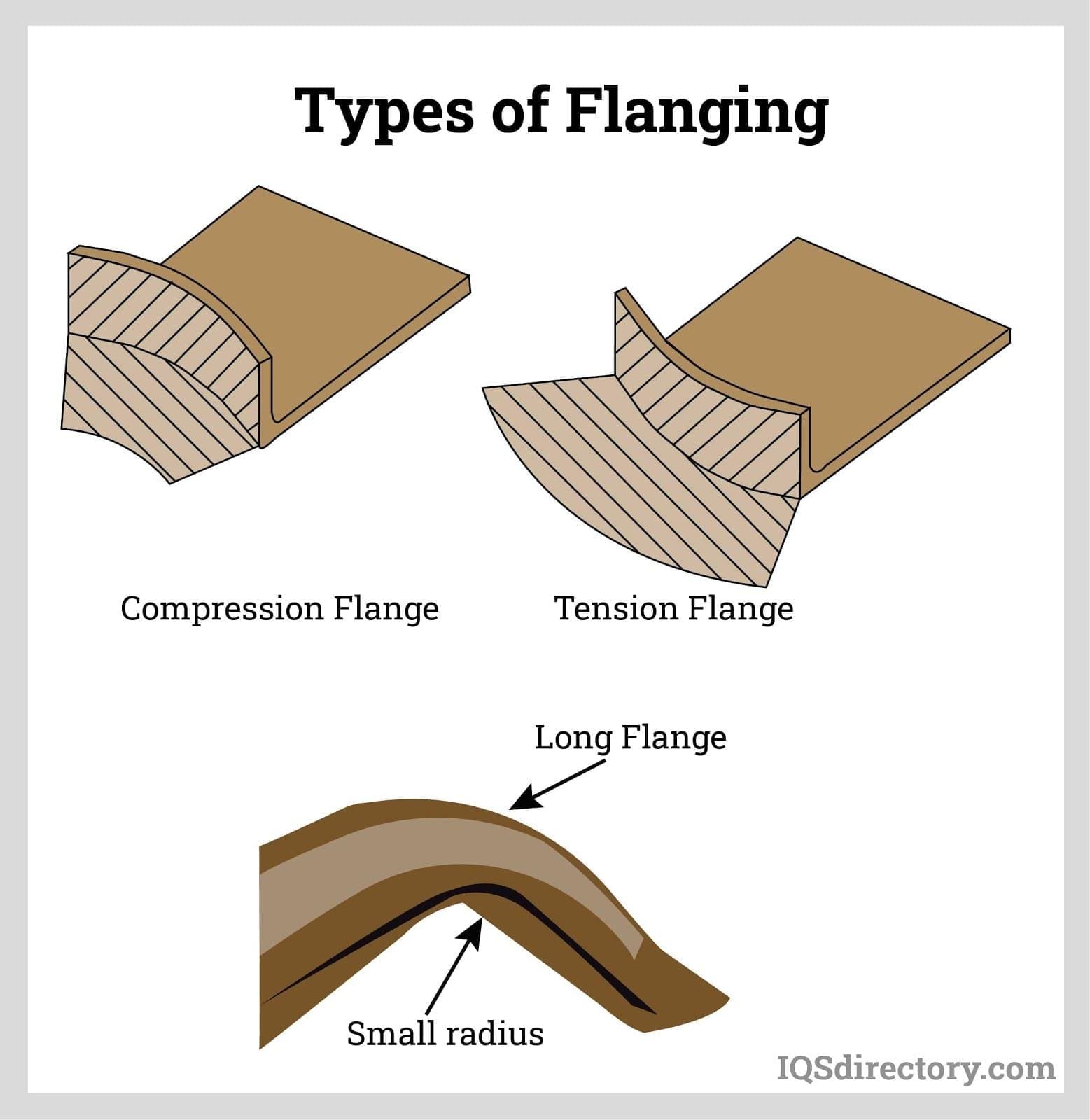

Flanging

The workpiece is bent by flanging along a curved axis. Stretching and shrinking are the two sorts. The length of the tab affects the flanging process, which frequently involves tension and compression. However, with just a simple downward push motion, it is possible to create curves or corners.

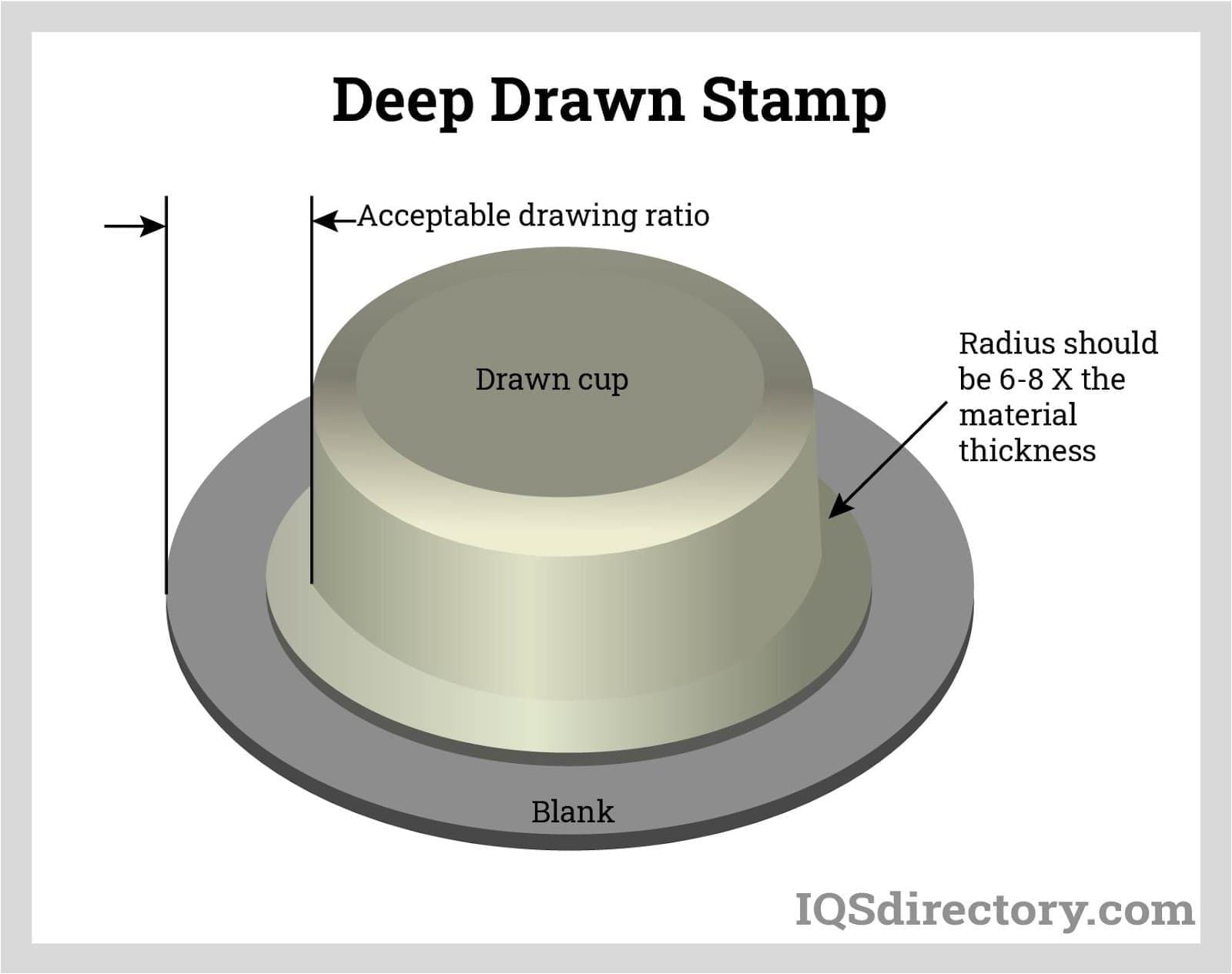

Drawing

Drawing is a metal flow process that substitutes a different form with the same surface area for the workpiece's surface. The metal is still thick after being reshaped. Since it impacts how the part can be moved, cut, and expelled, the drawing orientation is crucial. Deep drawing is a type of drawing. Since it is non-directional, the direction may be vertical, up, or down.

Stretching

Tension and thinning increase the workpiece's surface area. For painting and finishing, it creates an incredibly smooth surface. High-pressure binding is used in dies to stop the metal's flow. Stretched metals are typically resistant to dents. Pre-stretched material is displaced into an alternate geometry.

Coining

Applying intense pressure and reducing the metal's thickness creates a pattern on the workpiece.

Ironing

Similar to coining, its goal is to squeeze the workpiece at a depth that is 30% of the workpiece's thickness to minimize the wall thickness of the workpiece. Ironing raises the drawn vessel's length and provides a uniform wall thickness.

As opposed to forming dies, cutting dies cut or remove material to produce items. Below we discuss the various types of cutting dies.

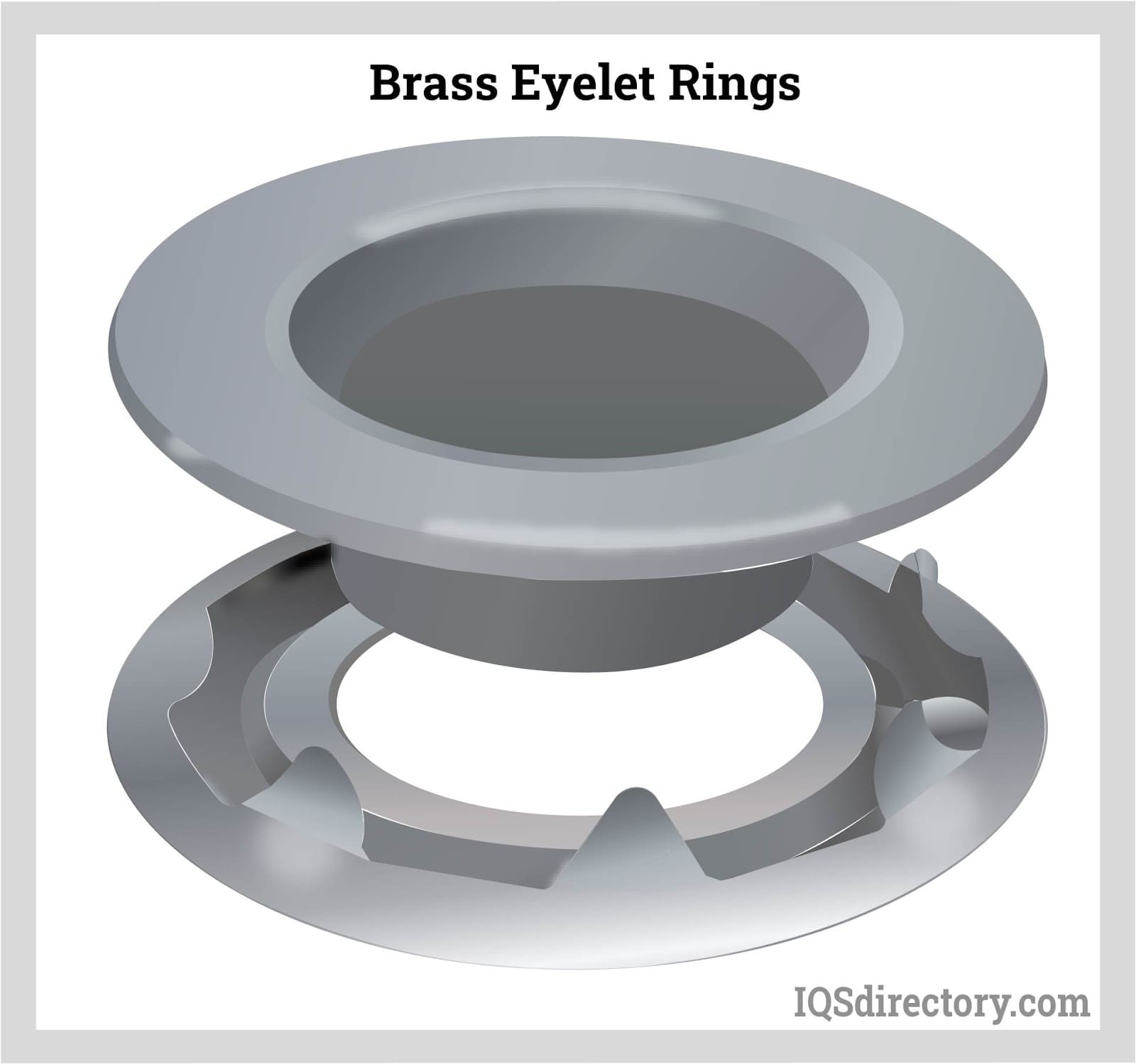

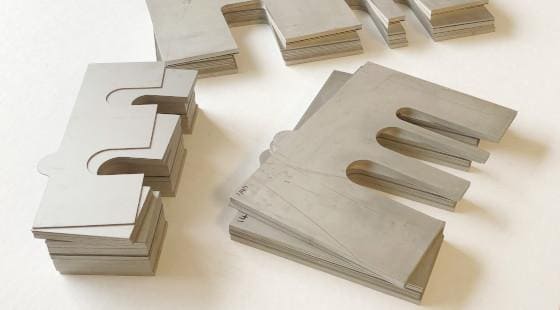

Blanking

When a metal strip is blanked, a section is removed along a certain contour line or shape. In the simplest terms, it involves separating one end of a strip from the other. In this process, the cutaway portion is the workpiece, and the remaining portion is scrap.

Piercing

Blanking and piercing go hand in hand. In blanking, the punched component turns into the usable part, which makes this difference between the two. With piercing, the portion is what is left after the excised piece is scraped off. The punch dimensions determine the size of the deleted component and the remaining hole.

Shearing

Although angle cuts are feasible, shearing generates a straight-line cut and is utilized for parallel cuts.

Trimming

To fit the appropriate profile, a form's outer edge is removed. This procedure is used to trim a flash, which is extra material surrounding a form during the die stamping process.

The top die trims the product, and the product enters the top die. To be ejected from the die, the product inside the die rises over the top die and is knocked out close to the top dead point. The knockout touches the bottom of the sketched product. When a product with a huge flange is being ejected, it's possible that it was deformed beforehand. Therefore, the knockout is produced to escape in the event of a product with a large flange in accordance with the drawing's diameter, and the ejecting is done at the flange part.

Notching

Bending or cornering procedures can be aided by notching. It is done to the outside of the workpiece to produce a particular profile.

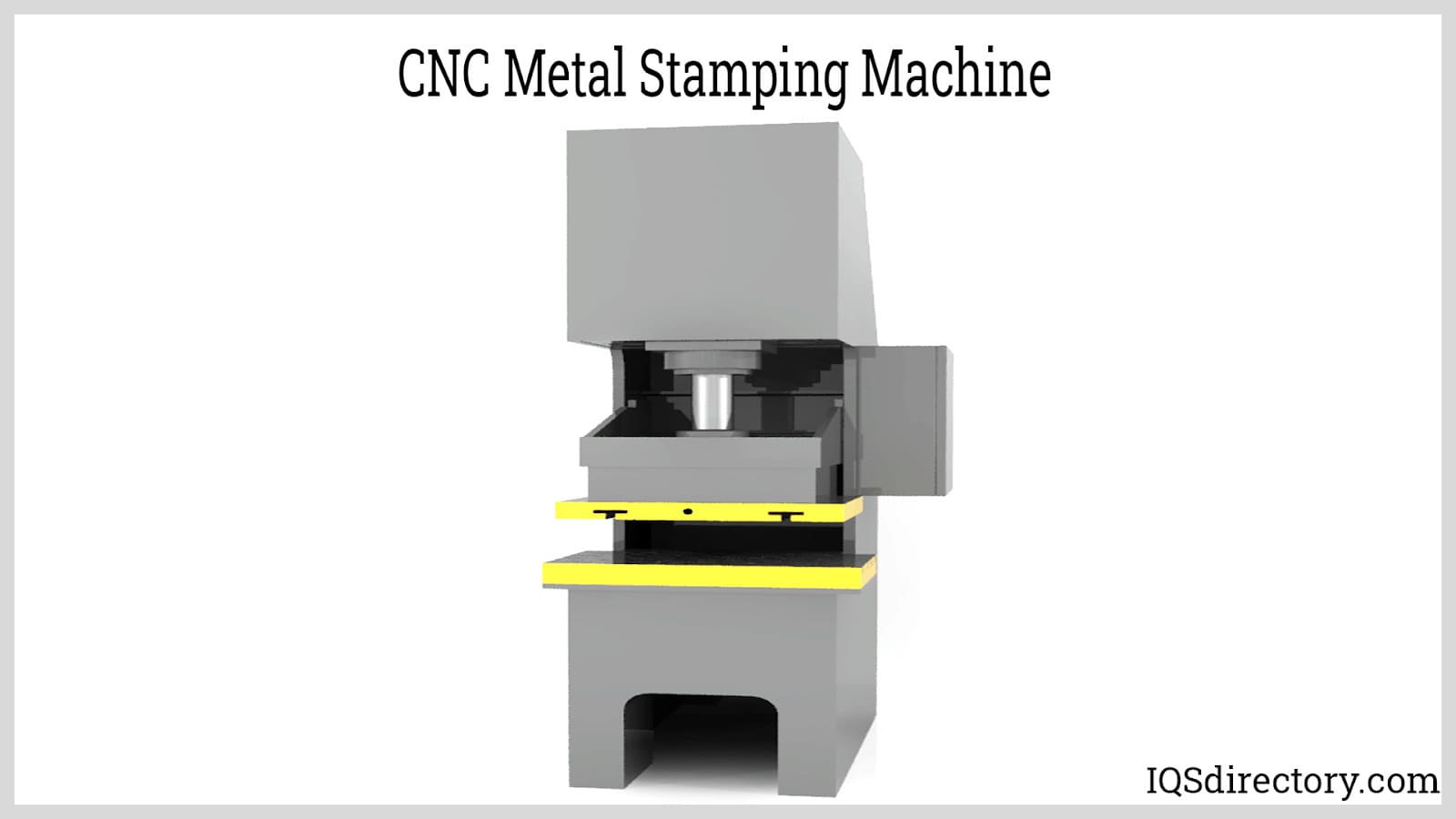

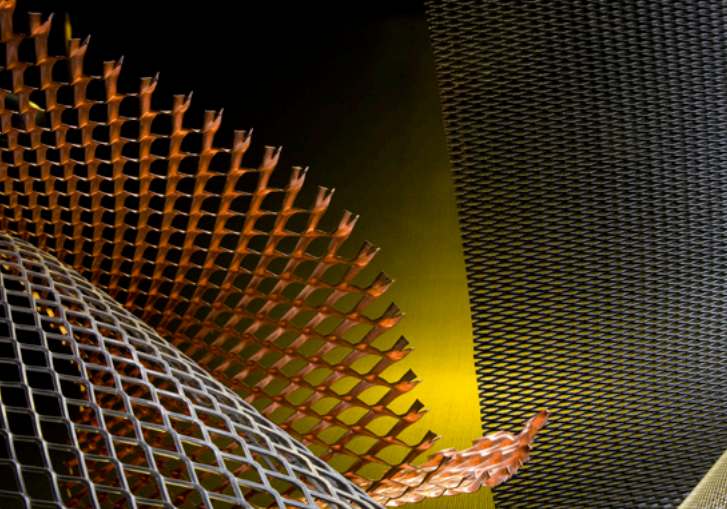

In addition to stamping, machines may cast, punch, cut, and shape metal sheets. Each stamped component can be produced with great precision and repeatability using machines that can be programmed or controlled using computer numerical control (CNC). Programs for computer-aided design (CAD) and electrical discharge machining (EDM) ensure accuracy. There are numerous tooling machines available for the dies used in the stampings. The stamping needs are met by progressive, forming, compound, and carbide tooling. Progressive dies can simultaneously create several pieces on a single piece.

Choosing the Right Die Stamping Manufacturer

To make sure you have the most constructive outcome when purchasing Die Stamping from a Die Stamping Manufacturer, it is important to compare at least 4 Manufacturers using our list of Die Stamping companies. Each Die Stamping Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Die Stamping business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Die Stamping companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

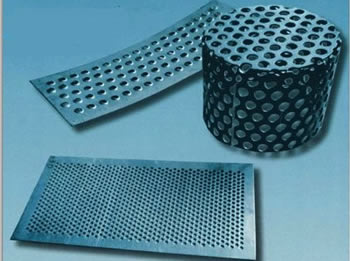

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services