Metal shims have found a wide range of uses in manufacturing and industrial operations. Made of several types of metals, this handy tool is capable of filling gaps between components, making minute adjustments to machinery, and providing space in medical devices. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

As a precision stamping specialist, we take pride in producing high quality custom metal stampings for our customers. We are experts in progressive and compound die stamping. Our capabilities allow us to manufacture parts from coil or strip material up to 6 inches wide and work with a range of thicknesses from .001 to .134 inches. Find out more on our website, or give us a call today!

At Cygnet Stamping & Fabricating, Inc., we specialize in providing comprehensive solutions for metal stampings tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of metal fabrication, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio...

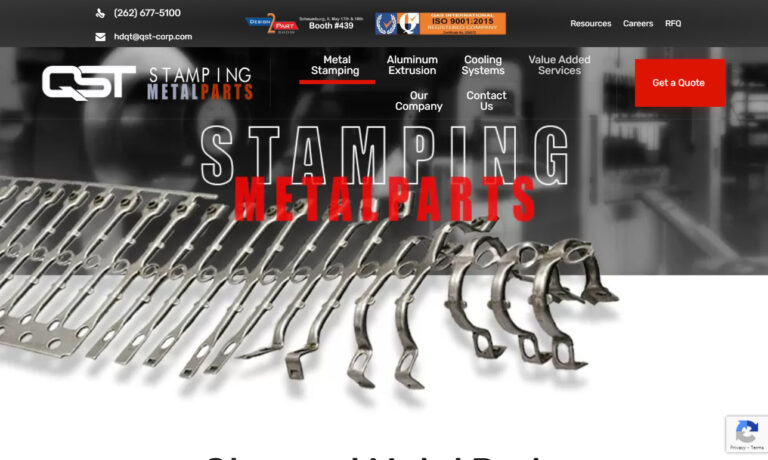

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

Lyons has specialized in precision metal stamping and contract manufacturing for over 65 years. As an AS9100, ISO 9001:2015 and ISO 13485:2016 certified company, you can count on quality first. Whether it’s a precision metal stamping requirement, a complex CNC machined part, an immediate rapid prototyping need or an intricate assembly, Lyons has the country’s top resources to help meet your...

More Metal Shim Companies

They are the small tool that is necessary, essential, and invisible that is a critical part of industrial applications.

There is an endless list of applications that depend on the precision and accuracy of metal shims. Produced and manufactured using different types of metal shaping processes, metal shims are carefully engineered to provide exceptional performance. Unlike the typical household shims, metal shims are produced to meet the highest tolerances and precision measurements, which is essential and necessary to meet the needs of engineering designs.

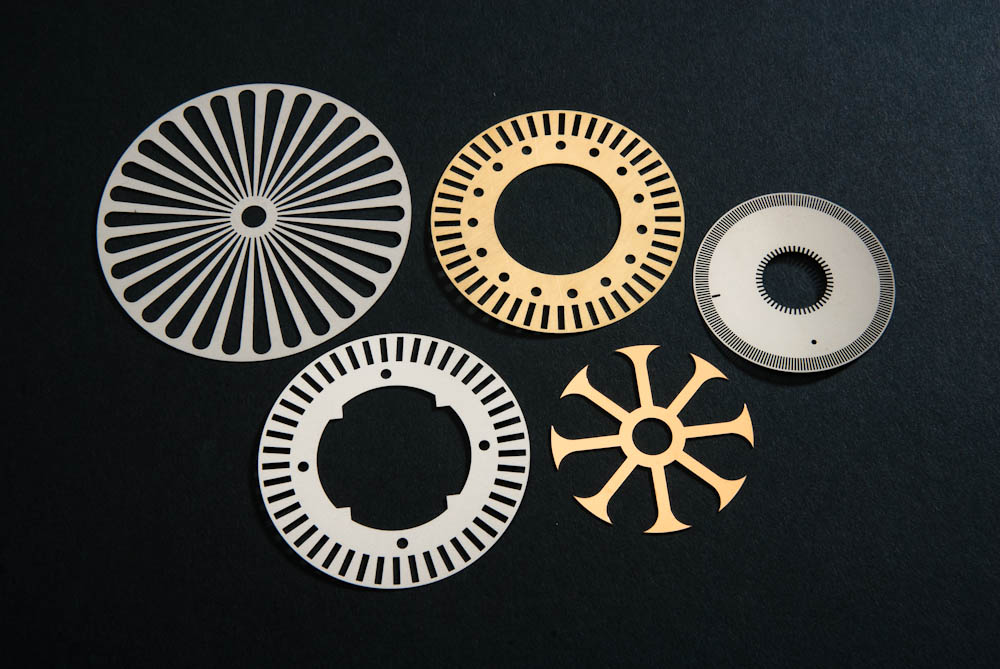

Metal shims are designed to adjust clearances, tolerances, and alignments as well as act as spacers to fill gaps, openings, and misalignments between parts. The term metal shim is a generic term that covers several different configurations of shims that include laminated shims, horseshoe shims, circular shims, and round shims. Although there are several standard types of shims, shim manufacturers are frequently asked to create custom shims to fit the needs of a unique designs.

Types of Shims

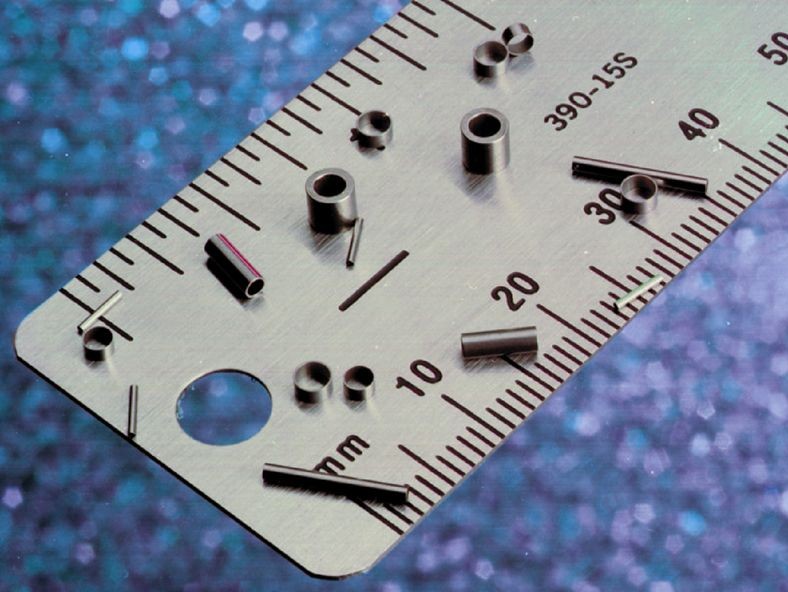

As a small, simple, and convenient component, shims have become an incredibly useful tool that has found use in so many sectors of business. They can have a gauge as low as 0.0005 inch with an exceptionally high degree of accuracy. The types of metal shims cover ones made in layers to thick ones to hold heavy machinery.

Laminated Shims

Laminated shims, or surface bonded shims, have a stack of peelable layers, which is like a post it note pad. They are made of layers of metal foil with the layers connected into a rigid shim that functions like a piece of solid metal. The thickness of a laminated shim is adjusted by peeling off pieces of the lamination to reach the appropriate height. Once a laminated shim is placed, it can withstand shearing forces and machining.

The layers of laminated shims are pressed together to cure with unwanted and deformed layers removed in order to have a smooth even surface. Laminated shims make it possible to use a single shim to fulfill the needs of an application and eliminate the need to have a warehouse of different sized shims.

Slotted Shims

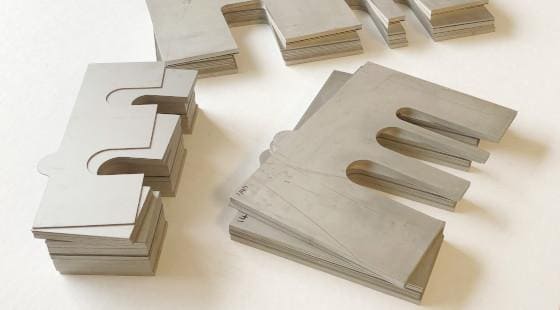

Slotted shims, known as horseshoe shims and “U” shaped shims, have a “U” shape such that they can fit around fasteners, screws, and shafts. They provide a snug fit for more accurate alignment and tighter tolerances. Metal slotted shims come in several different shapes with variations in the length of their legs and the number of slots. They are made of stainless steel, steel, galvanized steel, and aluminum.

The various shapes of slotted shims includes ones that have multiple slots, which are special ordered such that the slots have the correct dimensions.

Arbor Shim

Arbor shims, known as slitter shims, are washer-like shims used to prevent the axial movement of connected components. Although they have the shape of washers, arbor shims are manufactured to meet specific tolerances for perfect alignment. They are used for spacing milling cutters, saws, and grinding tools. Arbor shims are manufactured in thicknesses of 0.001 inch up to 0.018 inch.

Edge Bonded Shims

Edge bonded shims are a form of laminated shim with a slight difference. With laminated shims, full layers can be removed as needed to reach the appropriate thickness. With edge bonded shims, the layers above and below the edge of the shim can be removed, which makes this type of shim easier and more convenient to use. Additionally, edge bonded shims have layers of different thicknesses that make it easy to adjust the final thickness.

Tapered Shims

Tapered shims, known as wedge shims, are made to support heavy loads and help balance tools, machinery, and equipment. They are used for applications that have a tapered surface and can make assemblies tighter by pushing pieces apart. The design of tapered shims allows engineers to make minute, slight, and precision adjustments.

Flat Sheet Shims

Flat sheet metal shims are used in applications where hardness, flatness, smoothness, and accuracy are essential. They may be used with other types of shims such as slotted shims, tapered shims, and round shims to serve as a platform or spacer. Flat sheet metal shims are made from cold rolled low carbon steel in various sizes and thicknesses with the standard size being 6 inches by 18 inches in thicknesses that can accommodate any application.

The applications that make use of flat sheet metal shims are tool and die set up and machine alignment, assembly, repair and maintenance.

Shim Rings

Different sized shim rings are used to fill gaps between machines and components alongside retaining rings. They are defined by their thickness, inner diameter (ID), and outer diameter (OD).

Uses for Metal Shims

The small invisible metal shim is an essential part of several industrial applications. Their key factor is how precisely and accurately they are able assist in the development of a project.

Fill Gaps: Shims are used to close gaps and make materials level, which is especially true for construction projects.

Leveling: Shims are placed or driven between surfaces and equipment to level them.

Adjust Clearance: For the sake of precision and accuracy, shims are placed between components to reduce or increase clearance.

Protection: Copper and aluminum shims are used to protect computer processors from heat sinks.

How Metal Shims are Manufactured

In the majority of cases, metal shims have to be cut to custom dimensions before they can be used. As with the manufacture of any metal product, there are a few ways that metal shims can be made to meet the exacting requirements of industrial applications.

CNC Milling

CNC processing has become a vital part of modern manufacturing and is used to create shims of different shapes. CAD designs of shims are downloaded into CNC machines and converted to different codes that guide the milling tool. CNC milling is a high precision process with tight tolerances and the ability to produce any geometric shape.

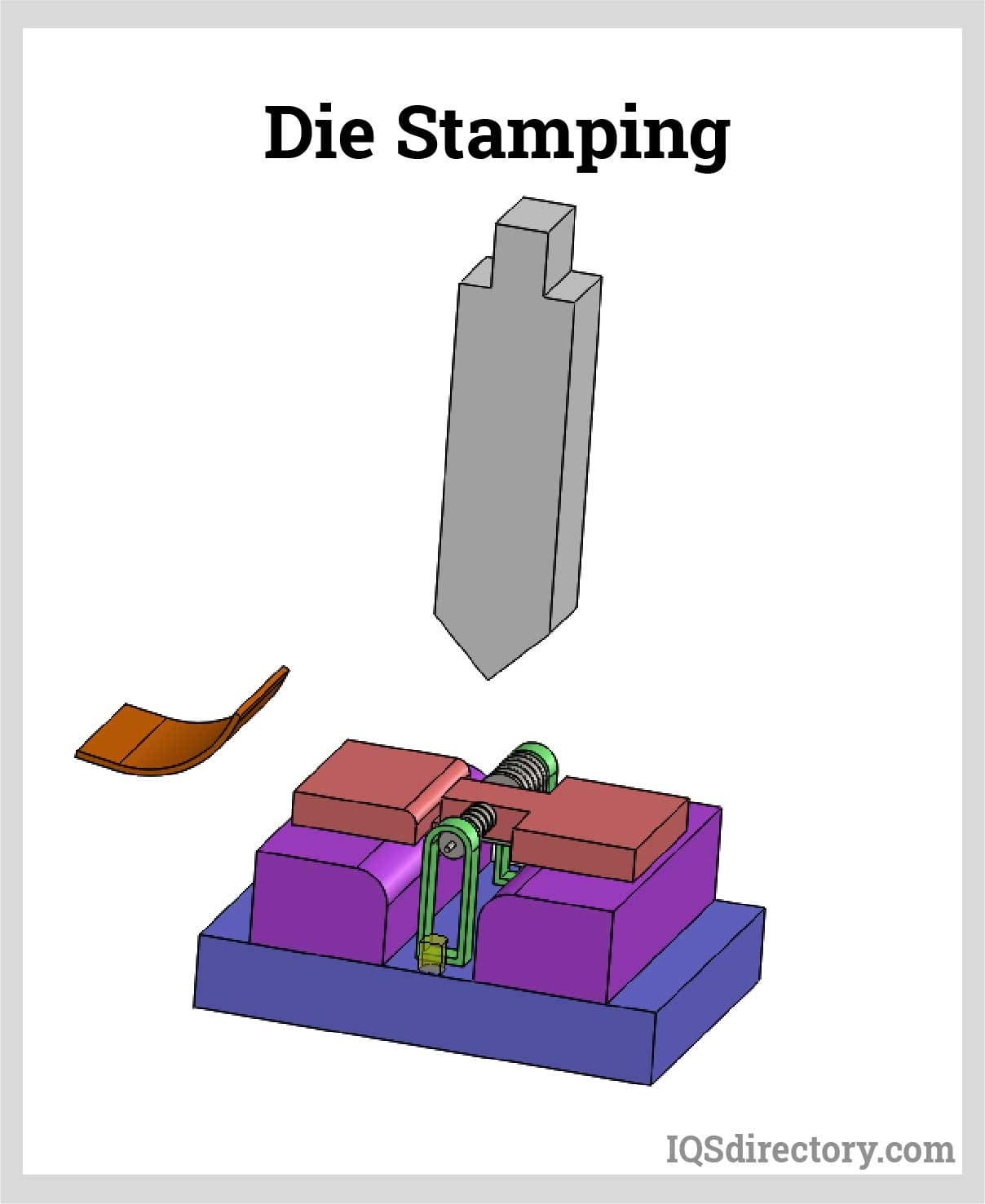

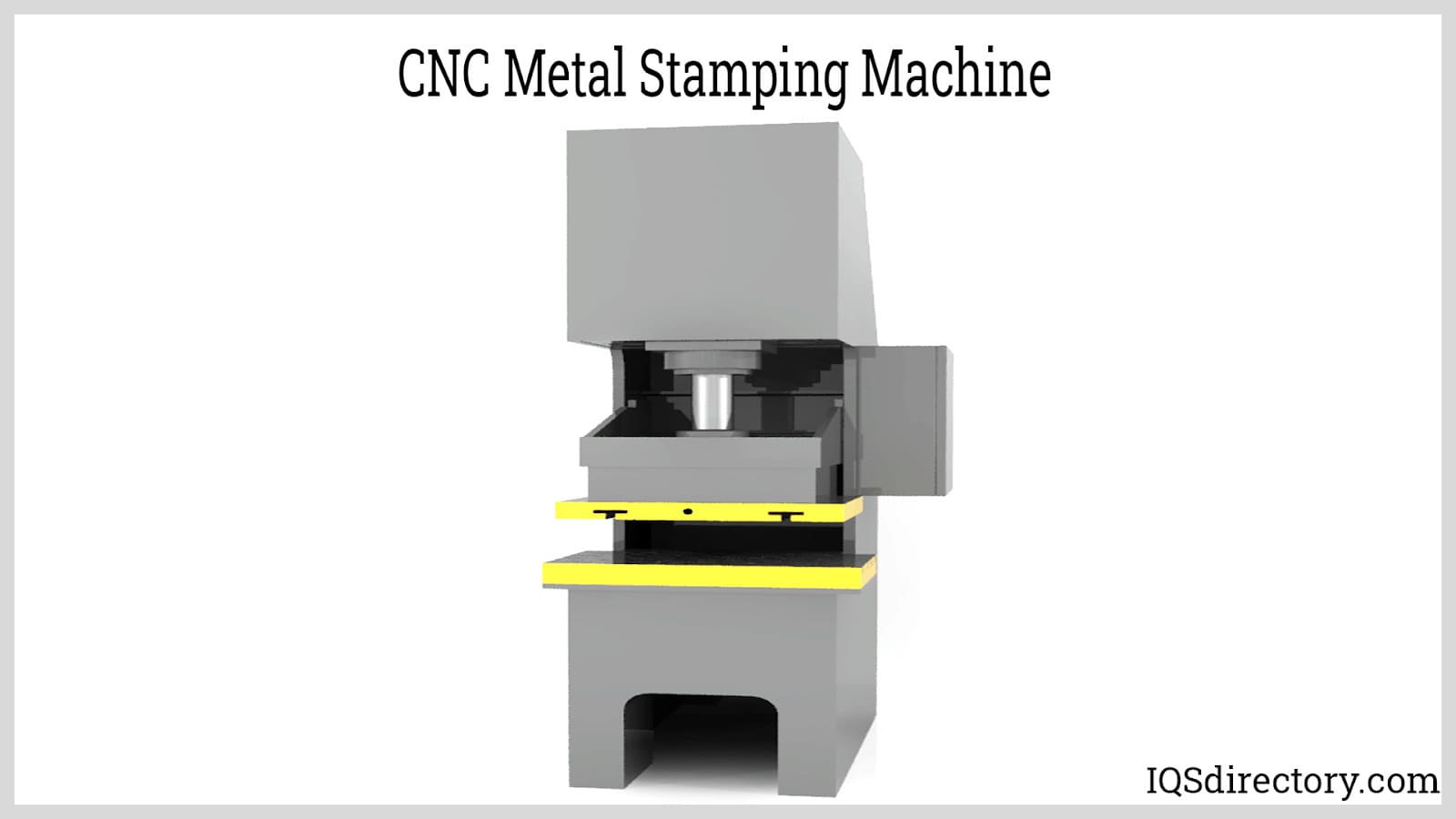

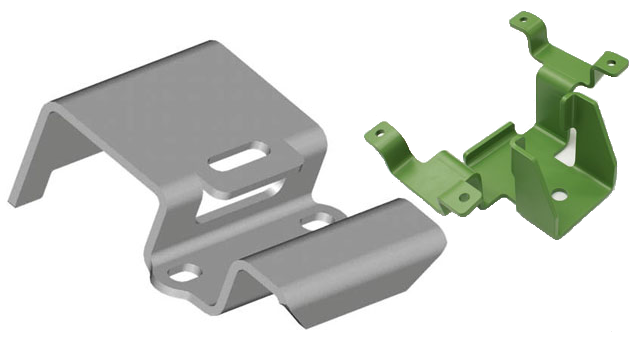

Stamping

A stamping machine, with a die that has the geometry of the shim, uses tons of force to cut coiled metal. The process of stamping can produce large quantities of shims in a short time. The limitation to stamping is the need to create dies for custom shims and only one size shim can be produced.

Laser Cutting

Laser cutting uses directed thermal energy to cut through sheet metal to create shims. It is a precision process that can be programmed to manufacture complex geometries with tight tolerances. All forms of metals can be cut using laser cutting and different geometric shapes can be cut from the same sheet.

Broaching

Broaching CNC Machining

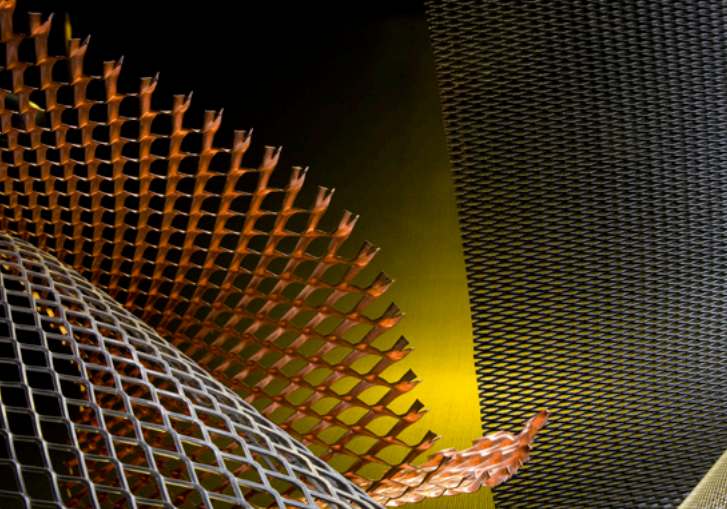

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

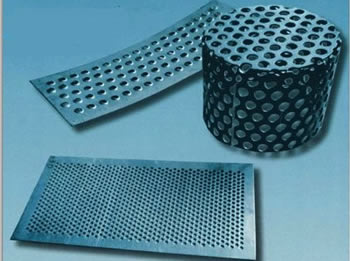

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services