Eyelets are small metal stampings that have a variety of uses in various industries. They are commonly used for reinforcing holes in leather, fabrics, or other materials to prevent tearing or fraying. They can also be used for decorative purposes, adding a finishing touch to clothing, shoes, or handbags.. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

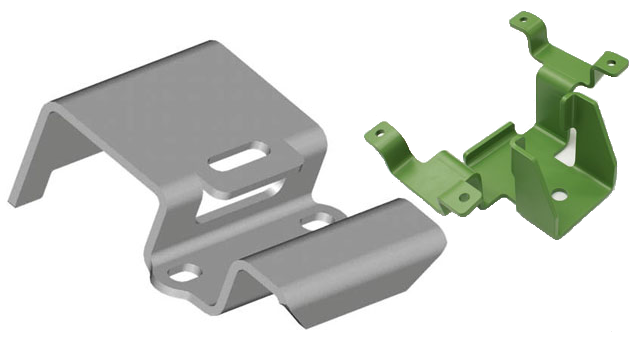

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

As a precision stamping specialist, we take pride in producing high quality custom metal stampings for our customers. We are experts in progressive and compound die stamping. Our capabilities allow us to manufacture parts from coil or strip material up to 6 inches wide and work with a range of thicknesses from .001 to .134 inches. Find out more on our website, or give us a call today!

At Cygnet Stamping & Fabricating, Inc., we specialize in providing comprehensive solutions for metal stampings tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of metal fabrication, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio...

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

Lyons has specialized in precision metal stamping and contract manufacturing for over 65 years. As an AS9100, ISO 9001:2015 and ISO 13485:2016 certified company, you can count on quality first. Whether it’s a precision metal stamping requirement, a complex CNC machined part, an immediate rapid prototyping need or an intricate assembly, Lyons has the country’s top resources to help meet your...

More Eyelet Companies

Production of Metal Eyelets

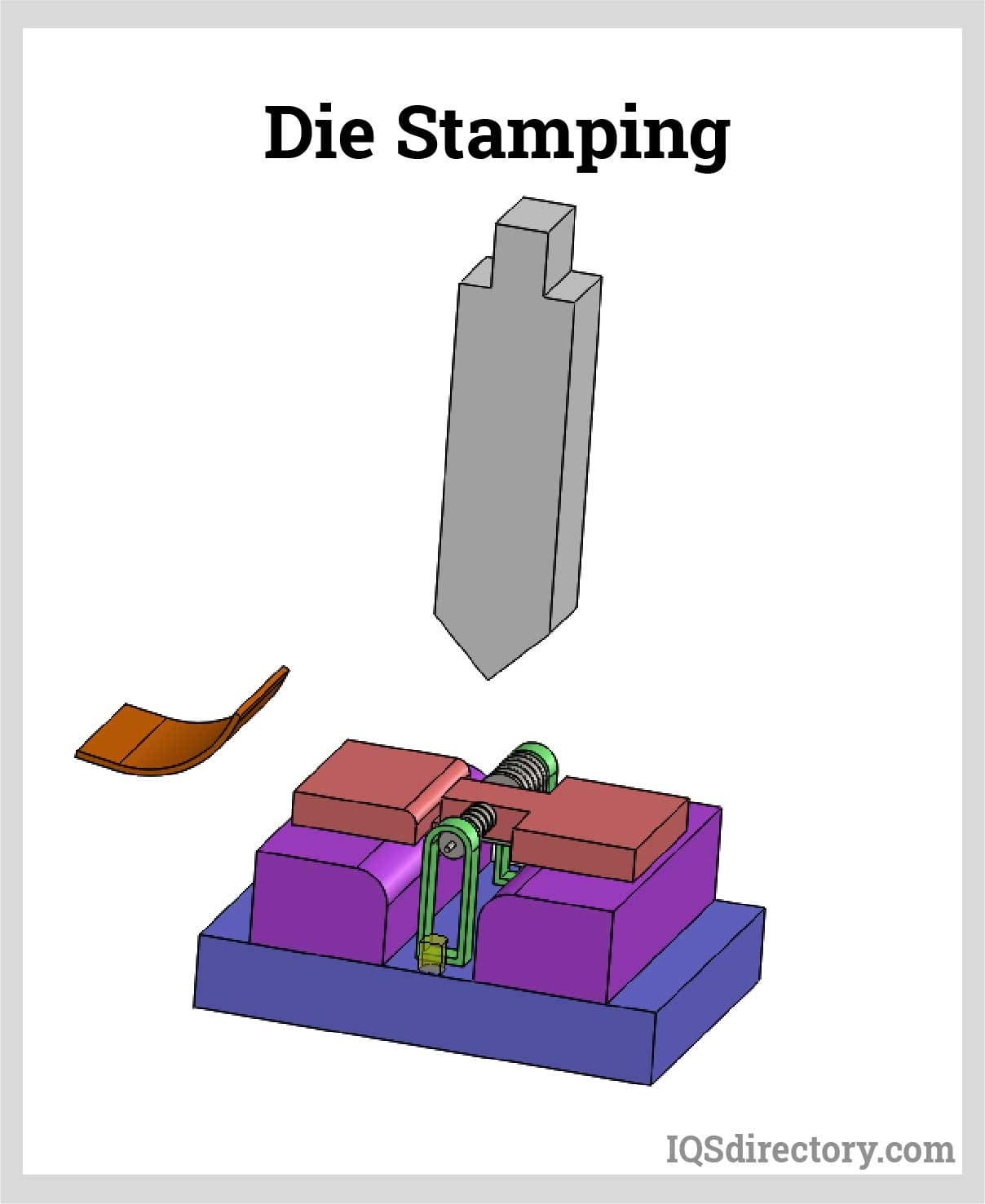

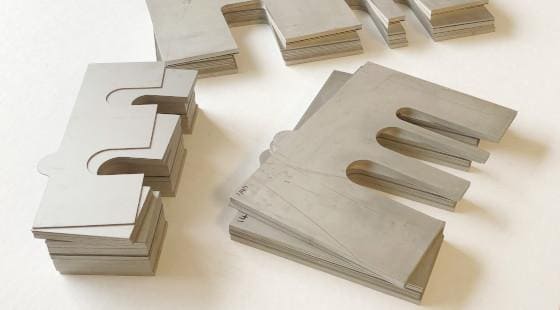

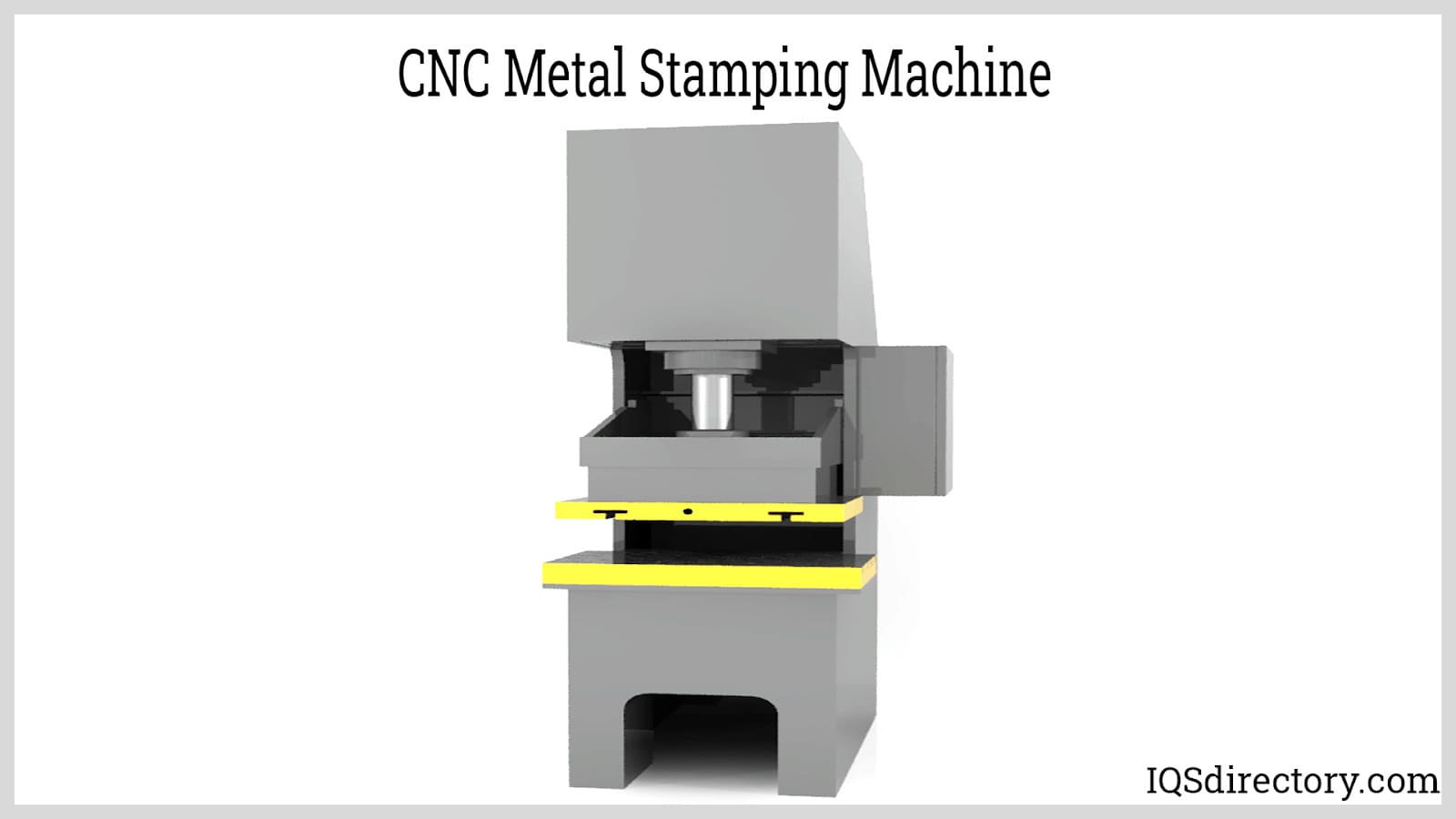

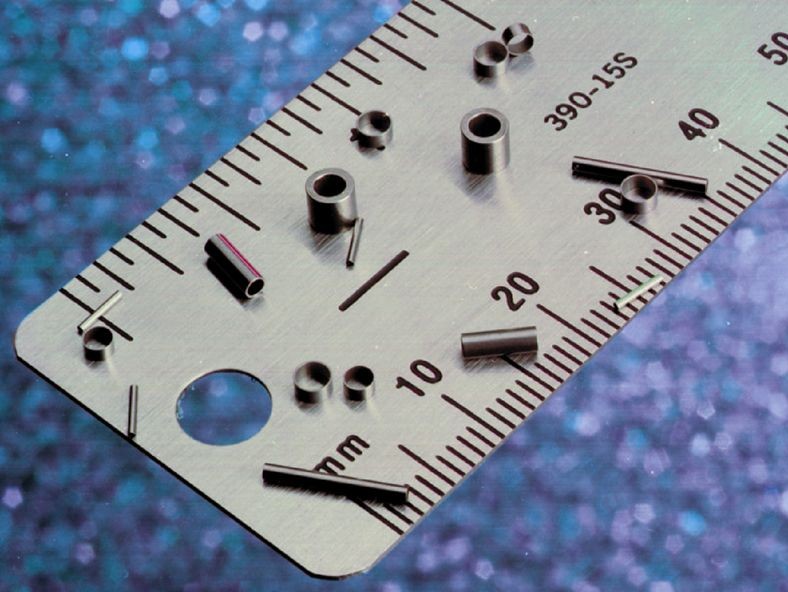

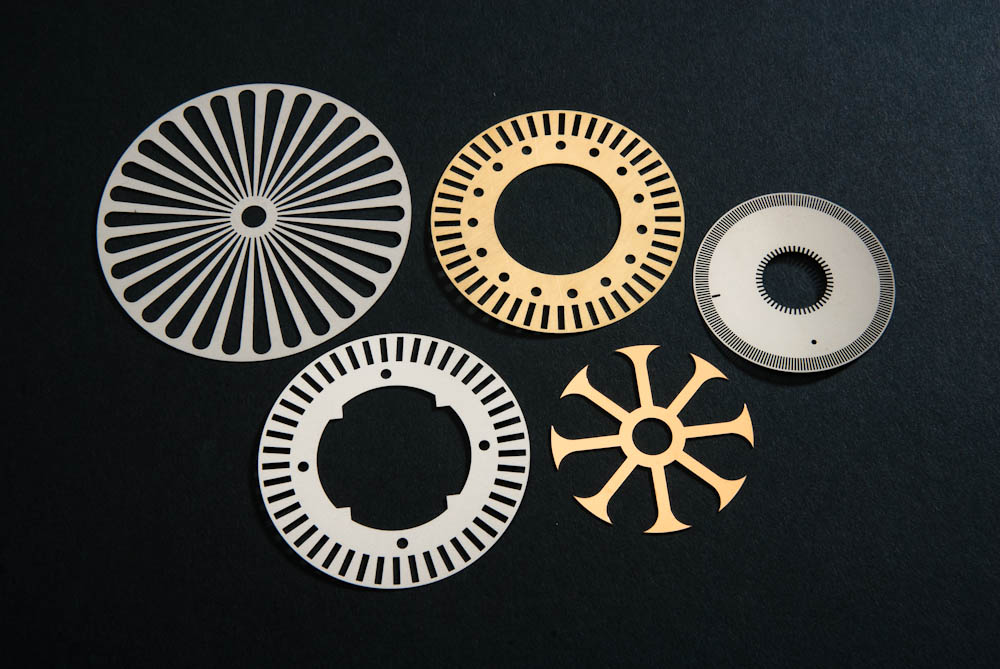

The production process for metal eyelets involves stamping a piece of metal into the shape of a small, cylindrical tube. Various processes can be used to produce metal eyelets, including progressive stamping, transfer stamping, and deep draw stamping. Progressive stamping is used for producing high volumes of eyelets at a low cost, while transfer stamping is used for creating more complex shapes. Deep draw stamping is used for creating deep, cylindrical shapes.

Materials Used in Metal Eyelets

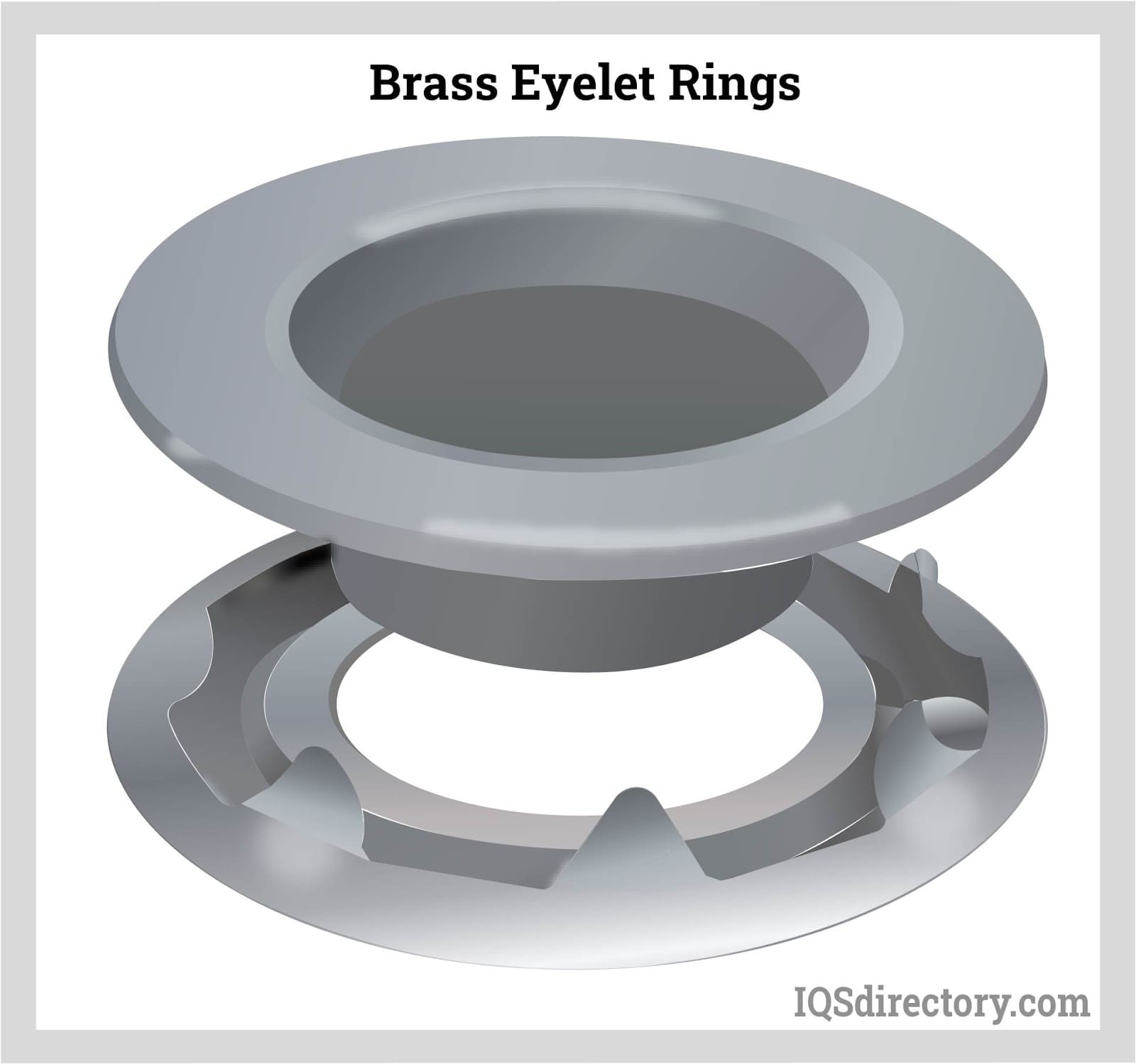

Metal eyelets can be made from a variety of metals, including brass, copper, stainless steel, aluminum, and nickel. Each metal has its own unique properties and benefits. Brass and copper are often used for decorative purposes due to their golden color, while stainless steel and aluminum are more durable and resistant to corrosion. Nickel is often used for its high strength and durability, making it a popular choice for industrial applications.

Negative Considerations Regarding Metal Eyelets

While metal eyelets have many benefits, there are also some considerations to keep in mind. The production of metal eyelets can have a negative impact on the environment, and some metals used in eyelets can be hazardous to human health. Regulations are in place to limit the use of certain metals in eyelets, such as lead and cadmium.

Benefits of Metal Eyelets

Despite these considerations, metal eyelets have many benefits, such as:

Durability

Metal eyelets are extremely durable and can withstand harsh environmental conditions. They are less likely to crack or break over time compared to plastic eyelets, and they do not deteriorate easily due to exposure to sunlight or other elements.

Corrosion Resistance

Some metals, such as stainless steel, are highly resistant to corrosion. This makes them an ideal choice for marine or humid environments where rust or corrosion can easily occur.

Aesthetic Appeal

Metal eyelets provide a sleek and professional look to the finished product. They come in a range of colors, finishes, and designs, making them a popular choice for designers and manufacturers.

Easy to Install

Metal eyelets are easy to install using hand tools or automated machinery, making them a cost-effective solution for manufacturers. They can be installed quickly and efficiently, reducing labor costs and increasing productivity.

Versatility

Metal eyelets can be used in a wide range of applications, from industrial to decorative. They are available in various sizes, shapes, and materials, making them a versatile fastening solution.

Increased Product Lifespan

Metal eyelets help to reinforce the material they are installed in, which increases the lifespan of the product. They prevent fraying, tearing, and other forms of damage, which can extend the life of the product and reduce the need for repairs or replacements.

Environmental Sustainability

Metal eyelets can be recycled, making them an environmentally friendly choice. They can be melted down and reused to create new products, reducing waste and conserving resources.

Applications of Metal Eyelets

As a result of their many benefits, metal eyelets have a wide range of applications in various industries, including:

The Fashion Industry

In the fashion industry, metal eyelets are often used in clothing, shoes, and handbags for both functional and decorative purposes.

The Automotive Industry

In the automotive industry, metal eyelets are used for safety equipment such as seat belts and airbags, as well as for decorative purposes in car interiors.

The Aerospace Industry

In the aerospace industry, metal eyelets are used for aircraft interiors and safety equipment.

The Medical Industry

In the medical industry, metal eyelets are used for surgical instruments and medical devices.

The Military Industry

In the military industry, metal eyelets are used for ammunition and body armor.

The Marine Industry

The marine industry utilizes metal eyelets for boat covers, sails, and other marine equipment.

The Packaging Industry

Metal eyelets can be used in the packaging industry for reinforcing holes in paper bags, cardboard boxes, and other packaging materials.

The Sporting Goods Industry

Metal eyelets are commonly used in sporting goods such as shoes, bags, and accessories.

The Upholstery Industry

The upholstery industry utilizes metal eyelets for furniture, curtains, and other decorative elements.

The Stationery Industry

Metal eyelets can be used in the stationery industry for securing pages in notebooks, creating custom tags, and other decorative elements.

The Electrical Industry

Metal eyelets are used in the electrical industry for securing wires and cables.

Choosing the Right Metal Eyelet Manufacturer

To ensure you have the most constructive outcome when purchasing metal eyelets from a metal eyelet manufacturer, it is important to compare several companies using our directory of metal eyelet manufacturers. Each metal eyelet manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each metal eyelet business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple metal eyelet companies with the same form.

Broaching

Broaching CNC Machining

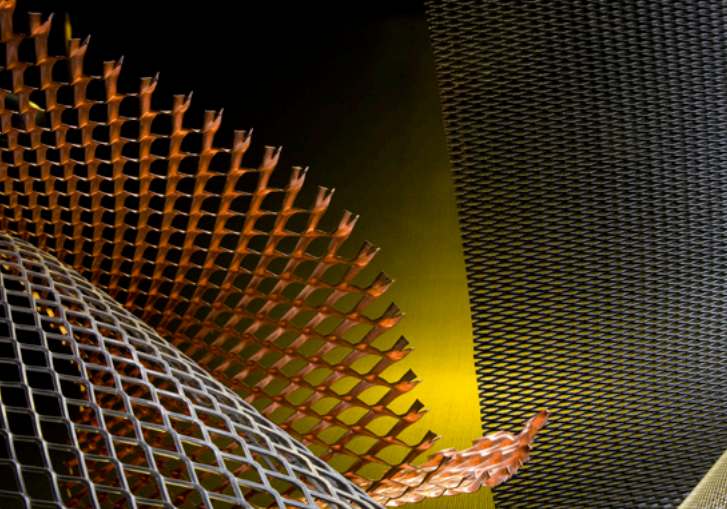

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

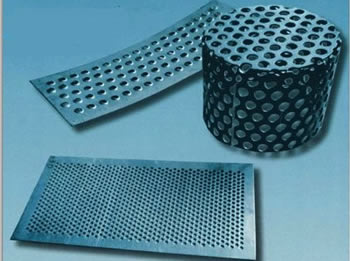

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services