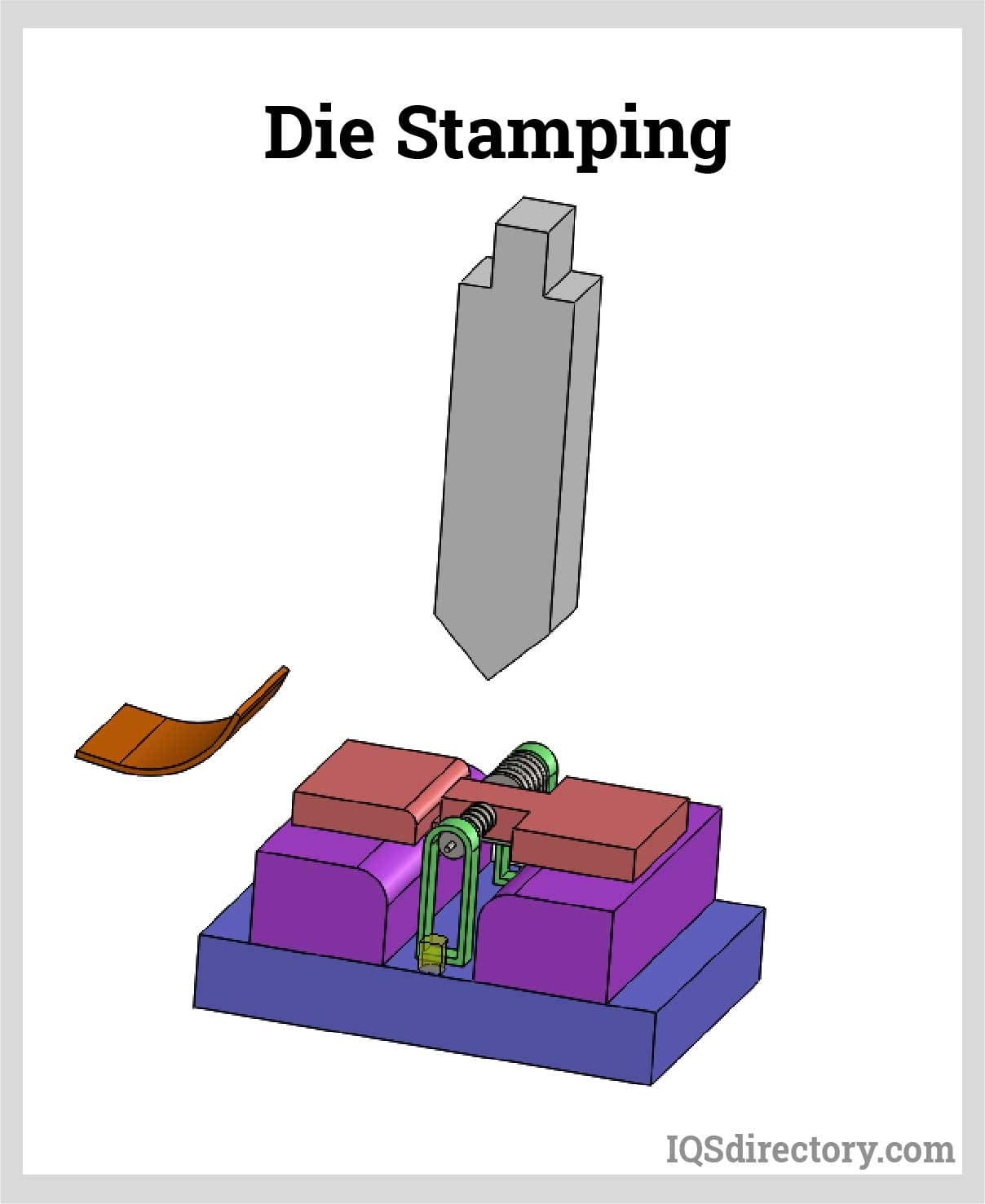

Sheet metal stamping is transforming metal sheets into functional parts or components. Flat sheet metal scraps are fed into a press where the desired shape is stamped out using a stamping tool, also known as a die. With great force, the die is pressed into or through the metal. Tons represent the amount of force applied in the procedure. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

As a premiere metal stamping company in the United States, we are fully capable of producing the engineered products you need to get to get your job done.

At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication. The company consists of two state-of-the-art plants, staffed with highly trained engineers and experts prepared to handle all of your projects. For unparalleled service...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

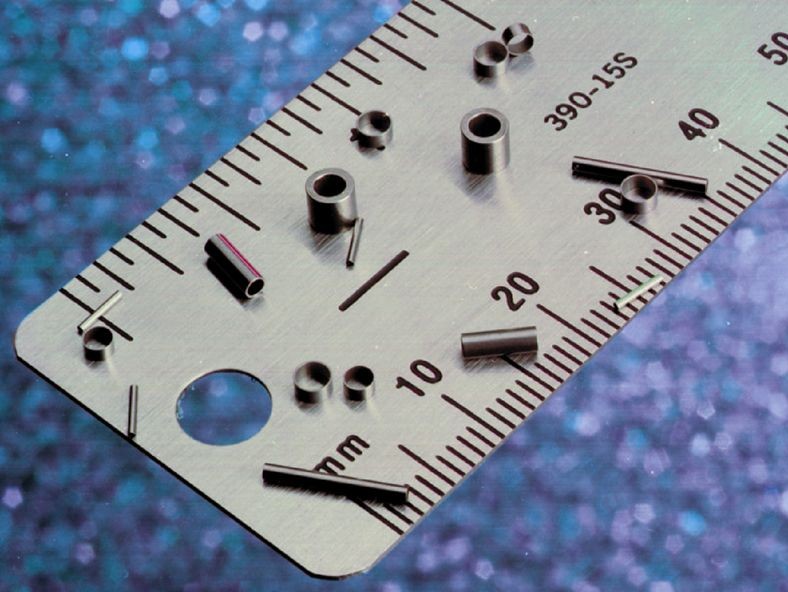

As a precision stamping specialist, we take pride in producing high quality custom metal stampings for our customers. We are experts in progressive and compound die stamping. Our capabilities allow us to manufacture parts from coil or strip material up to 6 inches wide and work with a range of thicknesses from .001 to .134 inches. Find out more on our website, or give us a call today!

At Cygnet Stamping & Fabricating, Inc., we specialize in providing comprehensive solutions for metal stampings tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of metal fabrication, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio...

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

Lyons has specialized in precision metal stamping and contract manufacturing for over 65 years. As an AS9100, ISO 9001:2015 and ISO 13485:2016 certified company, you can count on quality first. Whether it’s a precision metal stamping requirement, a complex CNC machined part, an immediate rapid prototyping need or an intricate assembly, Lyons has the country’s top resources to help meet your...

More Sheet Metal Stamping Companies

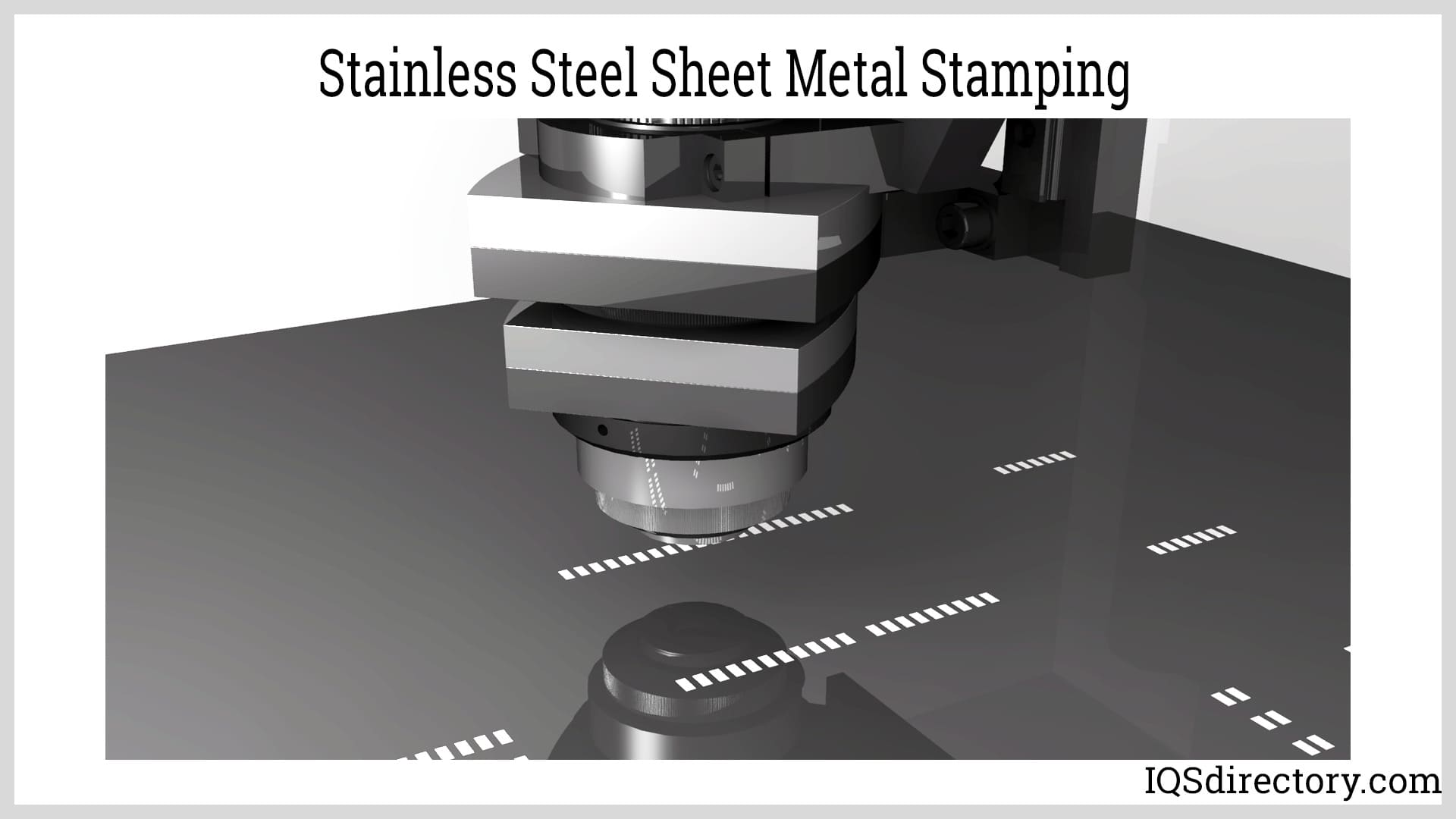

Sheet metal stamping doesn't involve heat, save during some specialized procedures. Instead, a cold-forming process is used. The part may come out hot even though no heat is applied because of the friction that the press's force causes to form between the metal and the die.

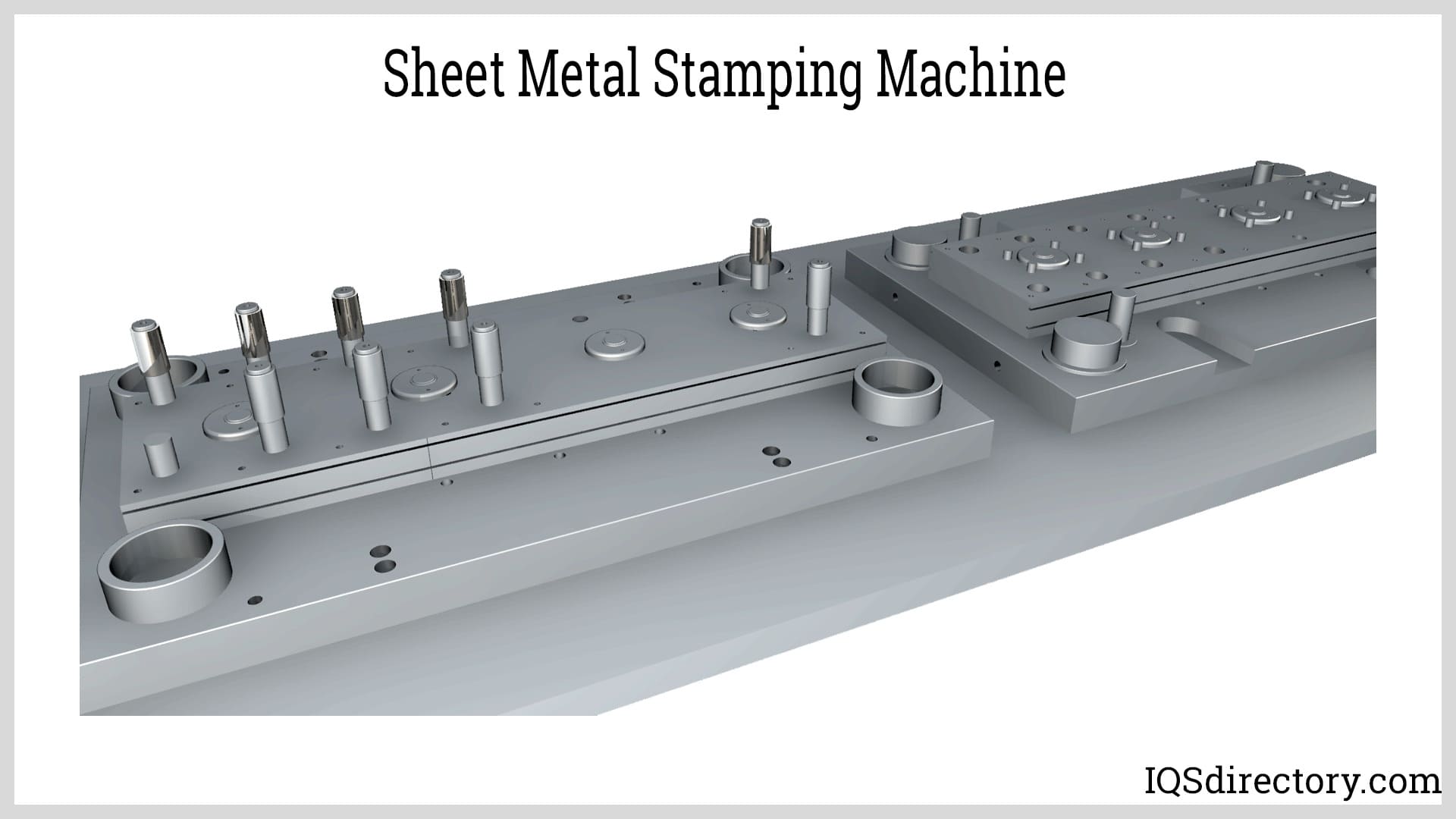

Sheet Metal Stamping Machines

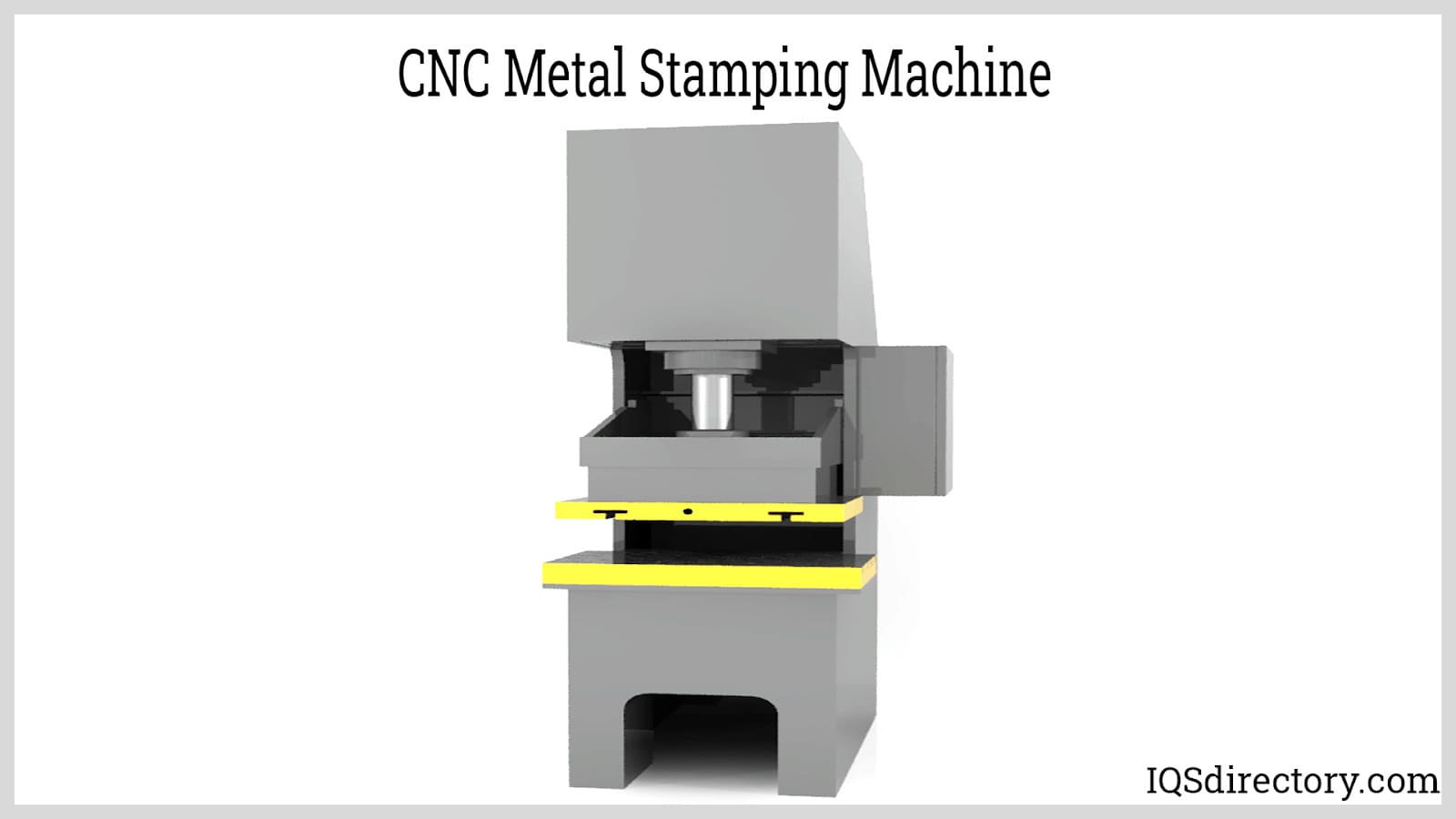

Specialized equipment is needed for sheet metal stamping processes. Stamping presses are the machines that are used the most. A press is a device that can apply pressure to a metal blank to shape it in the desired manner. It can be mechanical, hydraulic, manual, or CNC, depending on how frequently it is used, how many parts are produced annually, and how thick the pieces are. The most effective machinery for stamping sheet metal is hydraulic CNC presses. They can produce stamped metal components without the machinist's involvement if they have automatic sheet feeding equipment.

Common Sheet Metal Stamping Processes

The sheet metal, die, and press machine are the only three real parts in sheet metal stamping, albeit each part may go through several processes to reach its final shape. The following information covers typical procedures that could happen during metal stamping.

Forming

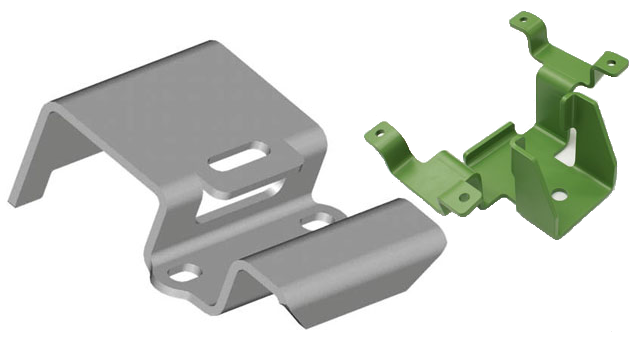

Pushing flat metal into a different shape is called "forming." Various techniques can be used, depending on the part's design needs. A series of procedures can change the shape of the metal from a relatively simple one to a sophisticated one.

Blanking

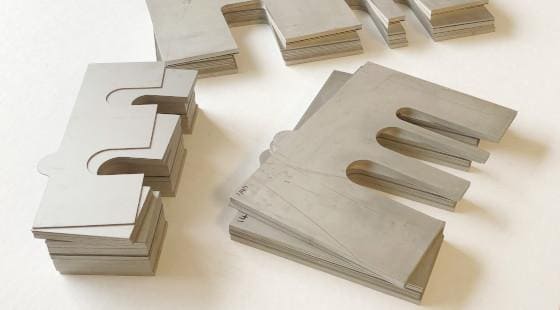

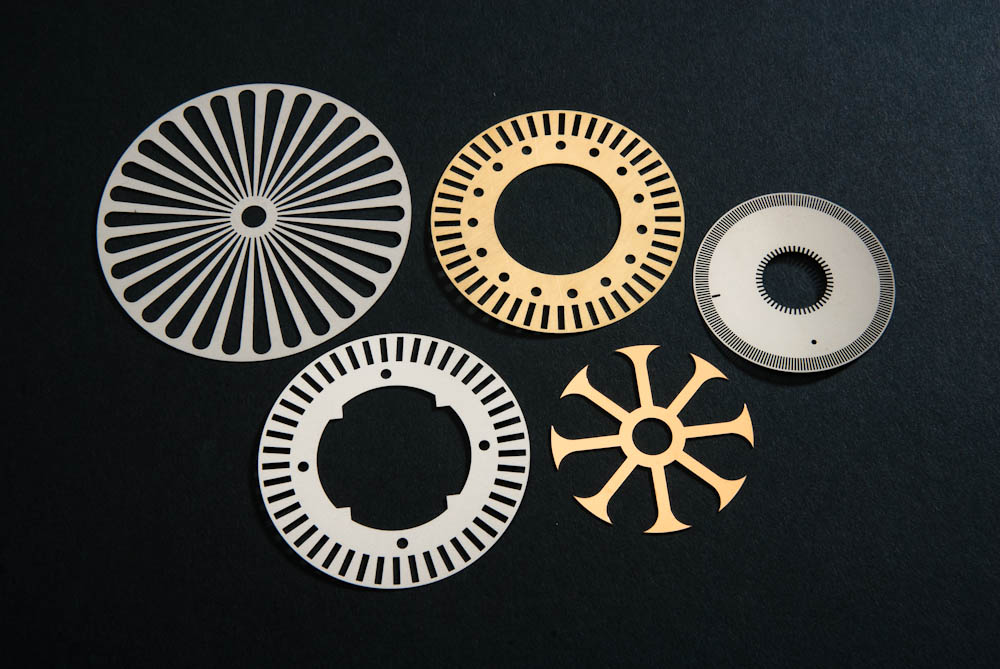

Blanking is the simplest way for stamping sheet metal. It begins with feeding the sheet or blank into the press, where the die is then used to cut out the desired shape. The completed item is referred to as a blank. The blank can either move on to the subsequent stage of forming or be a fully finished blank, which is the desired part.

Drawing

Vessels or substantial depressions are made during the drawing process, which is a more challenging task. Then, tension is used to accurately draw the material into a hollow to change its shape. Although the substance may enlarge while extracted, specialists strive to minimize stretching to maintain the substance's integrity. Drawing is frequently used to create culinary items, sinks for vehicles, and oil pans.

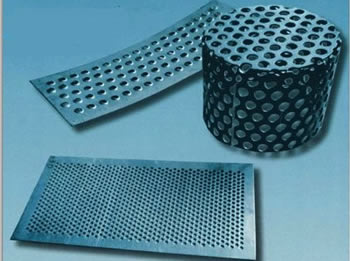

Piercing

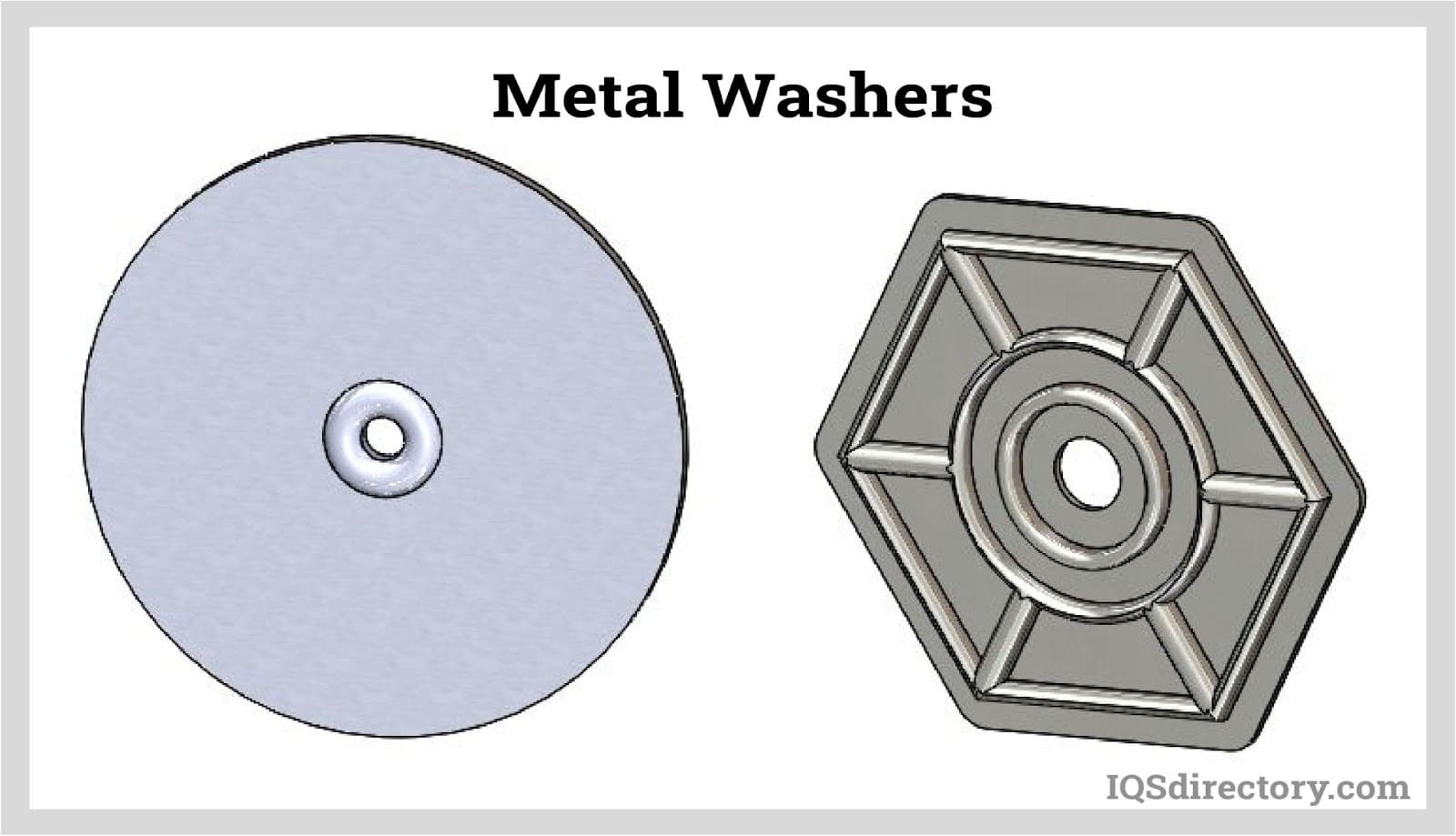

In contrast to blanking, piercing uses the material surrounding the edge of the perforated area instead of blanks. As an example, visualize cutting circles of rolled-out dough into biscuits. When blanking, the biscuits are saved; however, with piercing, the biscuits would be thrown away, and the hole-filled remains would be used to create the desired effect.

Materials Used With Sheet Metal Stamping

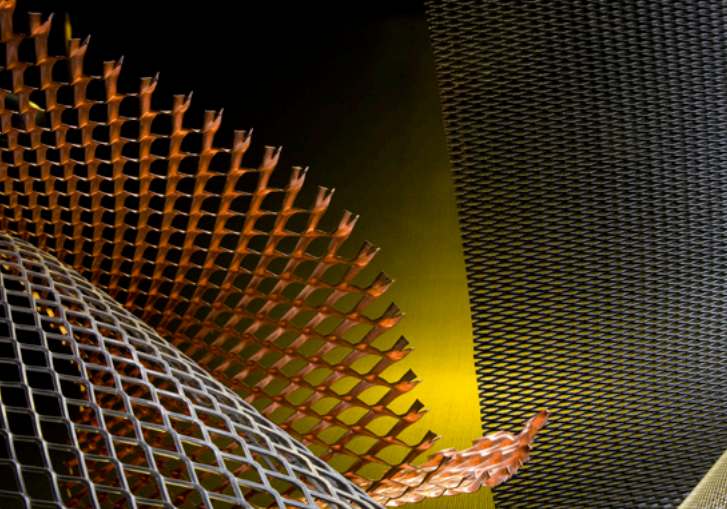

While almost any metal, even gold, can be stamped, sheet metal is the most typical type. The required type of part and desirable attributes, such as corrosion- and heat resistance, determine the type of metal utilized. Parts made of stainless steel, low- and high-carbon steel, aluminum, titanium, brass, bronze, copper, Inconel®, nickel alloys, and many more can be produced through sheet metal stamping.

Applications of Sheet Metal Stamping

During the stamping process, sheet metal is shaped into intricate pieces with the aid of highly specialized computer-aided drawing and production applications. As a result, stamping sheet metal quickly and efficiently yields excellent, long-lasting, heavy-duty products. In addition, because of how accurate they are, their results are typically more trustworthy and consistent than manual machining.

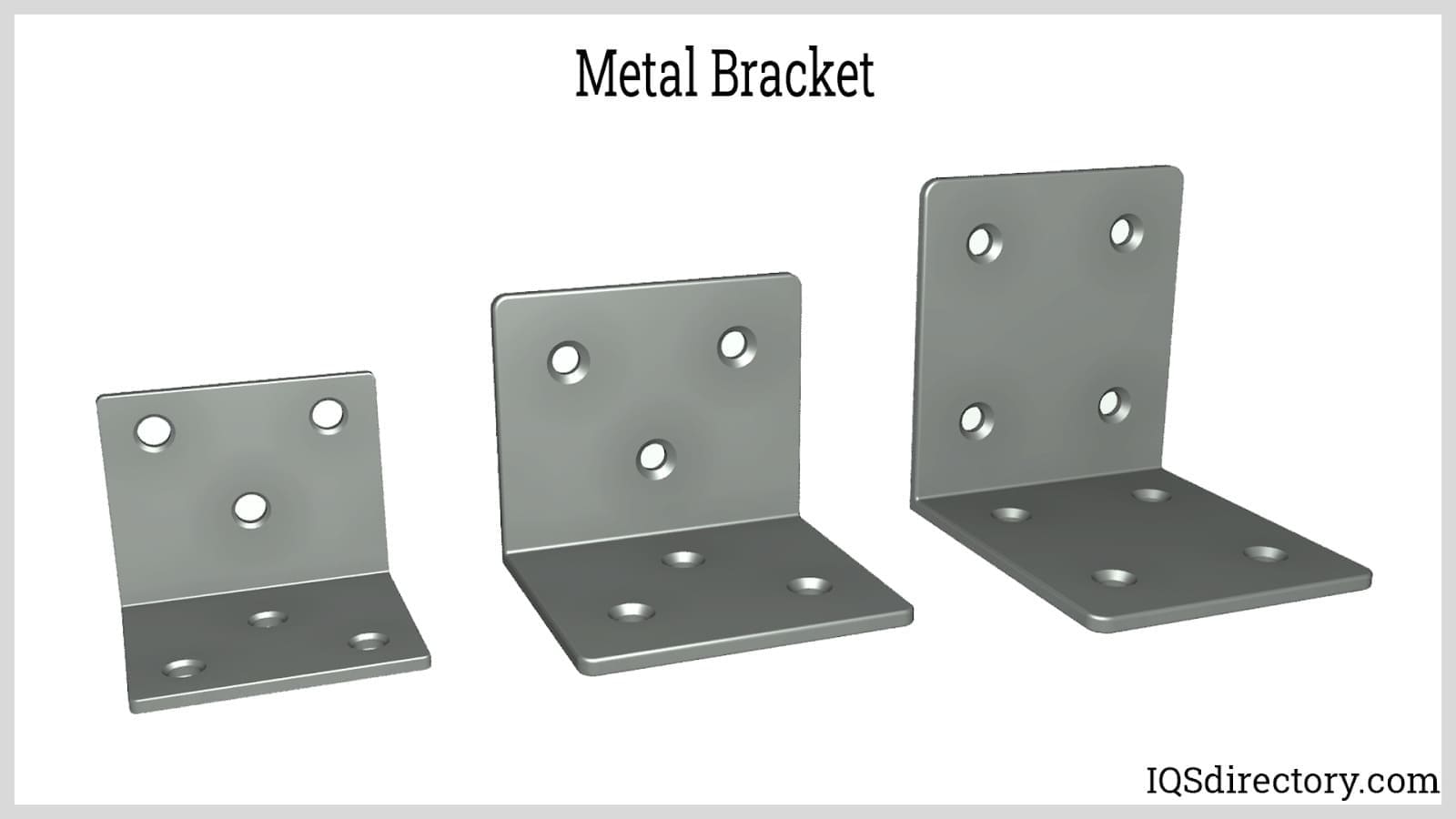

Parts for the automotive, renewable energy, medical, industrial, aerospace, hardware, and home improvement industries are made using sheet metal stamping. This list of industries is by no means complete. However, sheet metal stamping is widely used and in high demand in many industries.

Advantages of Sheet Metal Stamping

- lower die costs

- high precision and accuracy

- Sheet stamping offers a quick turnover.

- lower secondary costs

- extensive automation in comparison to other processes

- Compared to conventional procedures, metal stamping dies are typically less expensive to make and maintain.

- Compared to other metal manufacturing processes, secondary expenditures for cleaning and plating, for example, are less.

- Stamping equipment is generally simple to automate, and advanced computer control programs can increase precision, speed up production, and shorten turnaround times.

- The high degree of automation also drives down labor costs.

Disadvantages of Sheet Metal Stamping

The increased cost of presses is one drawback of stamping; another is that specialized metal stamping dies require a longer pre-production process and must be purchased or made.

Changing the dies might also be challenging if a design modification needs to be made during manufacturing.

Choosing the Correct Sheet Metal Stamping Supplier

To make sure you have the most beneficial outcome when purchasing Sheet Metal Stamping from a Sheet Metal Stamping Supplier, it is important to compare at least 4 Companies using our list of Sheet Metal Stamping manufacturers. Each Sheet Metal Stamping Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Sheet Metal Stamping company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Sheet Metal Stamping companies with the same message.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

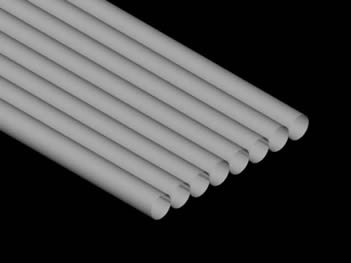

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services