Future Tool & Engineering Co Inc

Future Tool & Engineering Co IncRequest A Quote

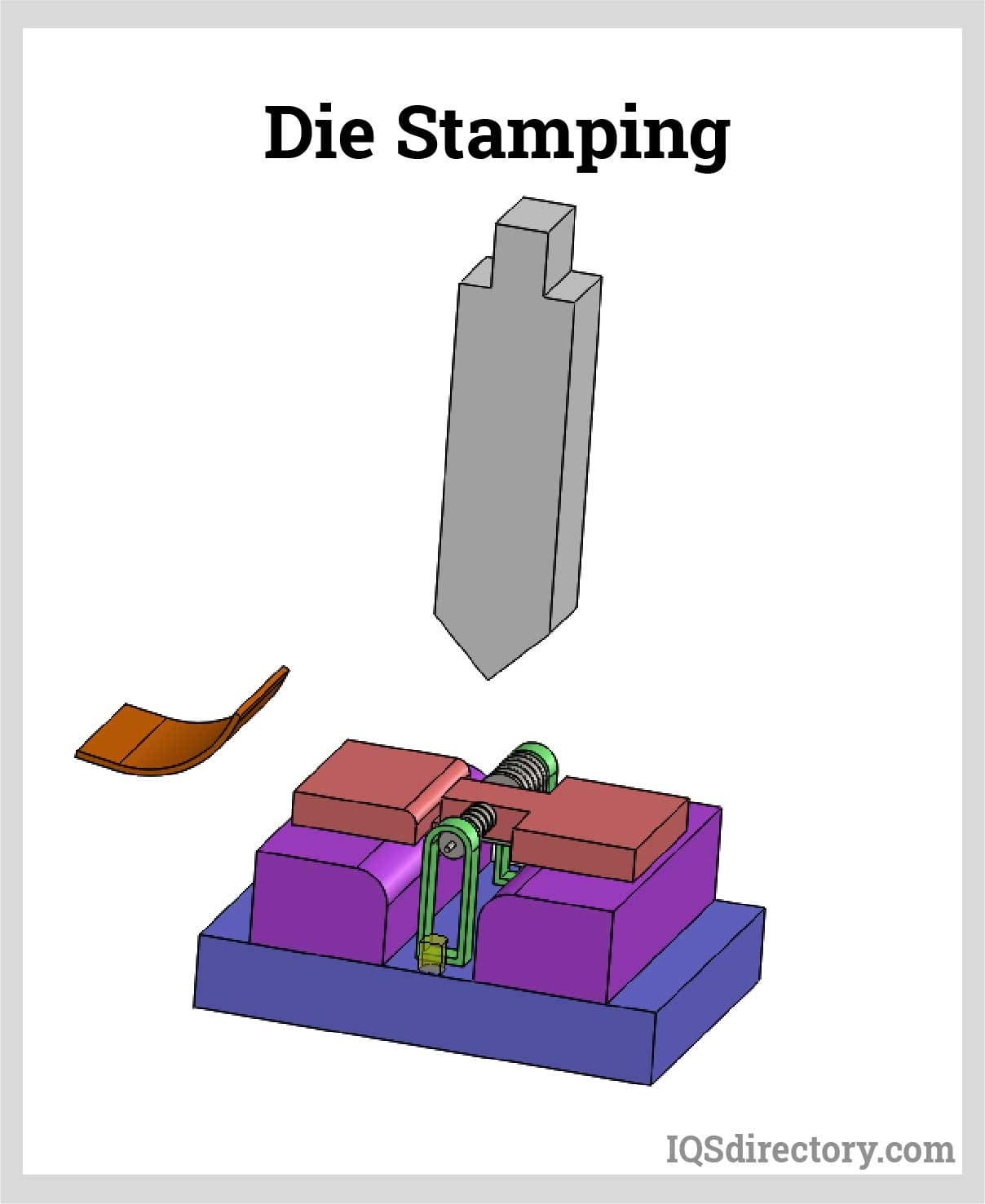

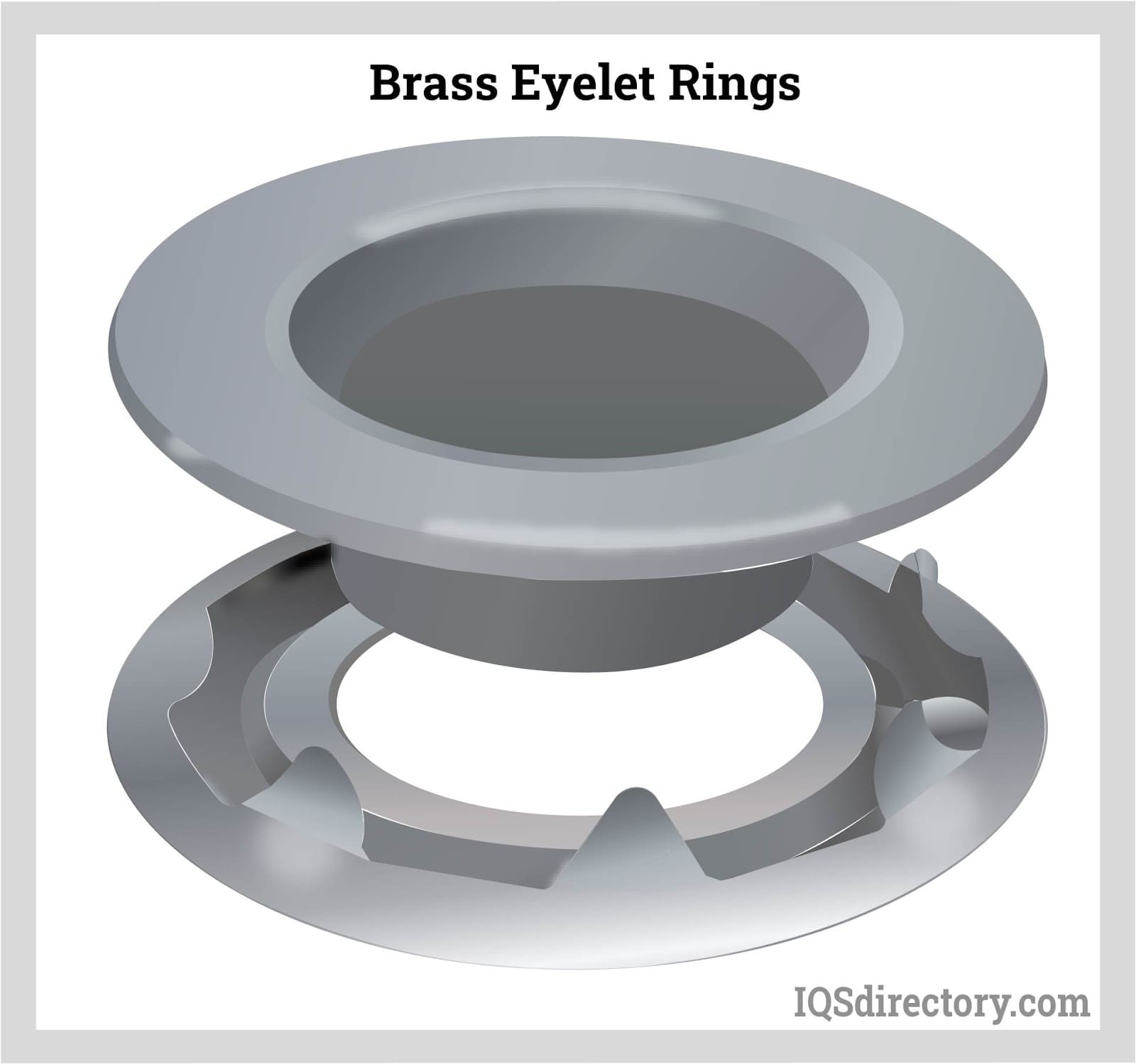

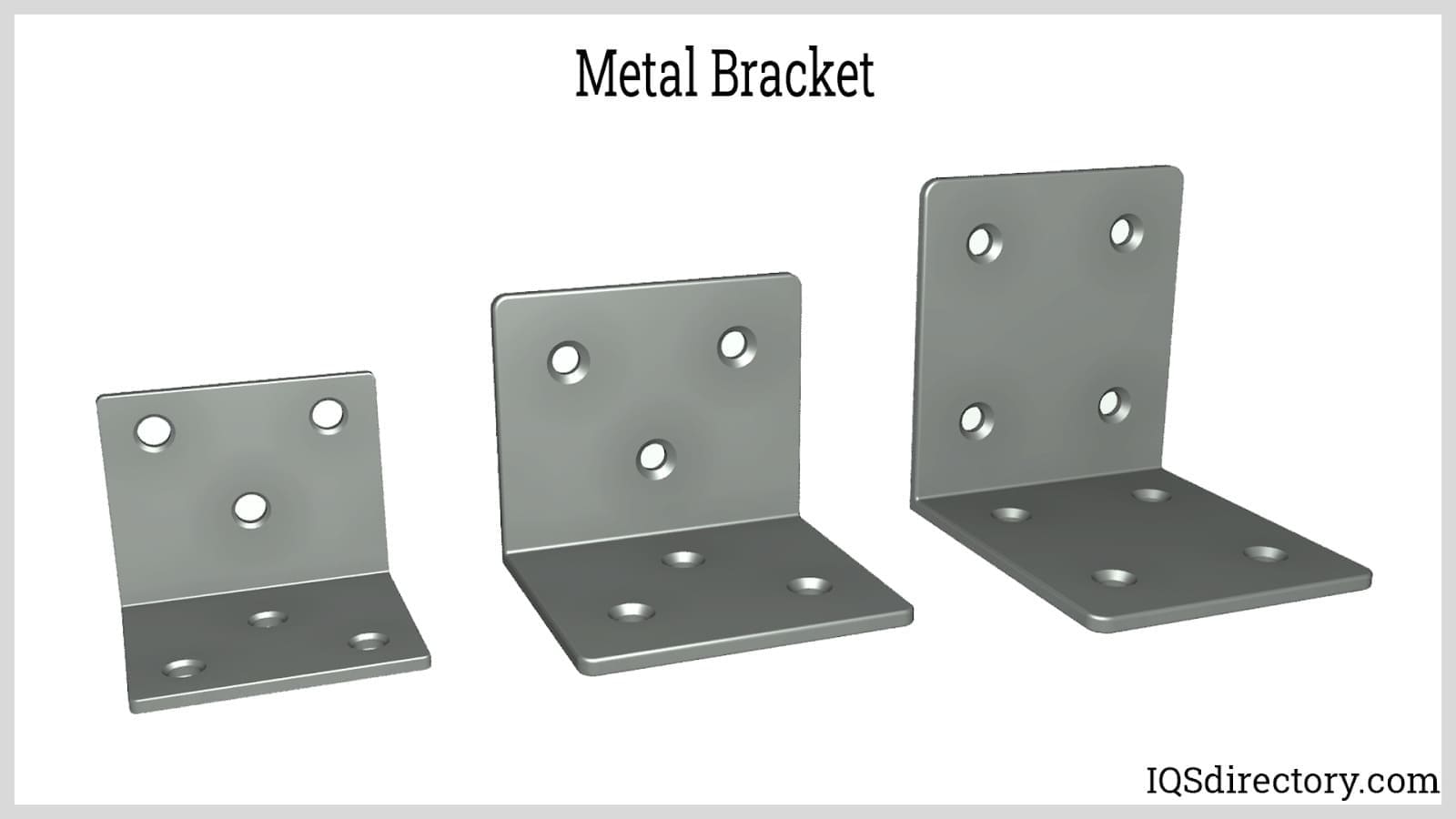

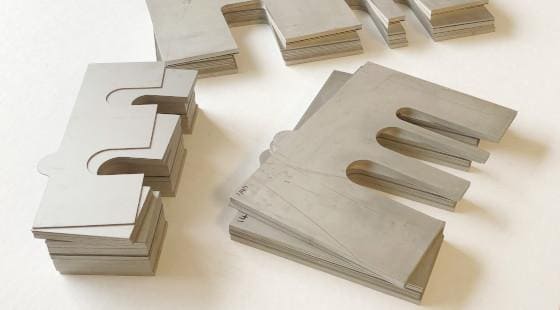

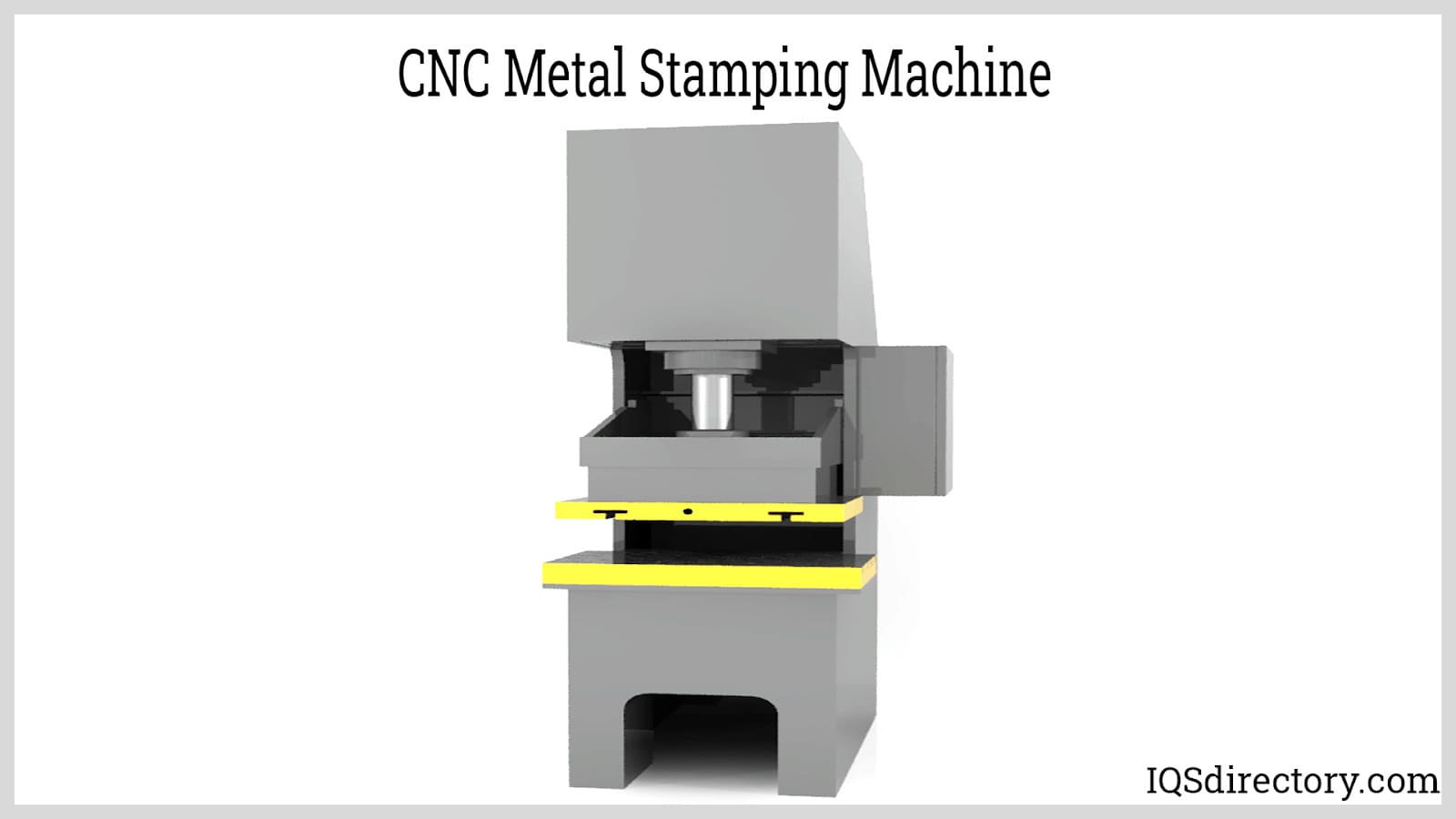

Columbus, INAt Future Tool & Engineering Co, our expertise revolves around delivering precision-crafted solutions tailored to diverse industrial requirements. We specialize in providing a wide array of capabilities and products that cater to various sectors, ensuring reliability, accuracy, and efficiency in our stamping services. Within our capabilities, we offer an extensive range of metal stamping services meticulously designed to meet varied needs. Our proficiency spans the stamping of various metals, including steel, stainless steel, aluminum, copper, and alloys. We leverage advanced stamping technologies and equipment to produce an assortment of components, parts, and assemblies with exceptional precision and quality. Understanding the critical role of precise stamping in manufacturing and fabrication, we prioritize delivering services that meet stringent quality and accuracy standards. Our team of skilled stampers, engineers, and technicians employ cutting-edge stamping techniques, sophisticated machinery, and meticulous quality control to ensure that our stamped components exhibit superior precision, fine detailing, and compliance with precise specifications. At Future Tool & Engineering Co, our commitment to superior metal stamping solutions drives us to set new industry benchmarks. We strive not only to provide top-tier stamping services but also to offer expertise, innovation, and a partnership built on trust and reliability. Through our dedication to advancing stamping technologies, embracing customer-centric approaches, and understanding industry demands, we continuously aim to exceed expectations and contribute to the success of industries reliant on precise and high-quality stamped components.

Broaching

Broaching CNC Machining

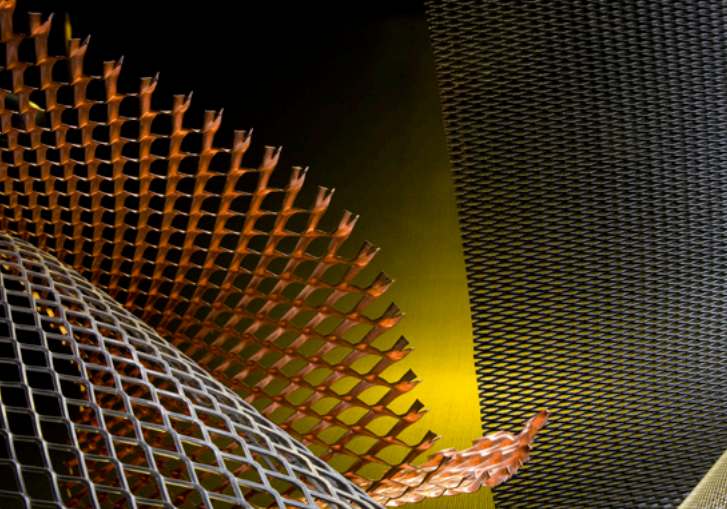

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

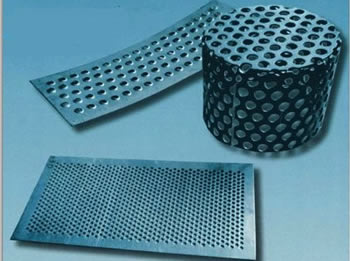

Metal Fabrication Perforated Metals

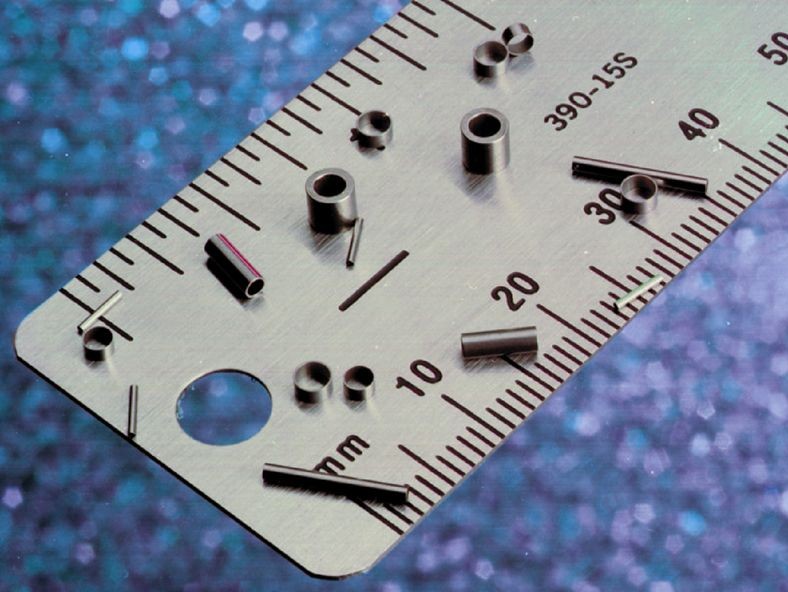

Perforated Metals Screw Machine Products

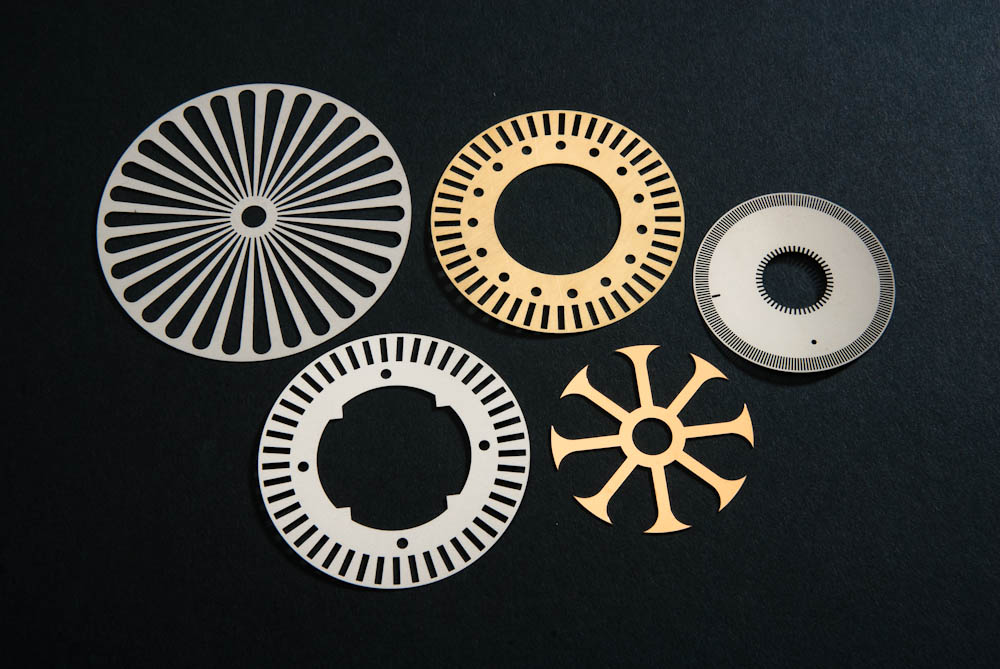

Screw Machine Products Metal Stampings

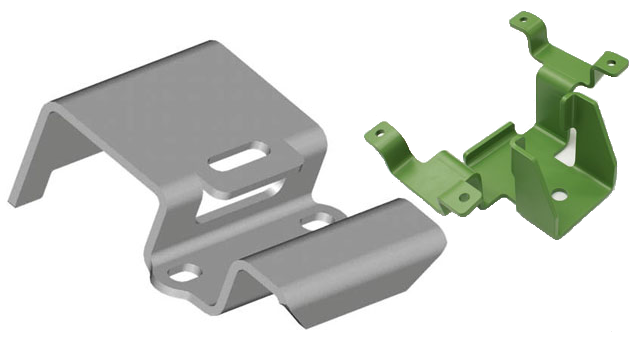

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services