Kapco Metal Stamping

Kapco Metal StampingRequest A Quote

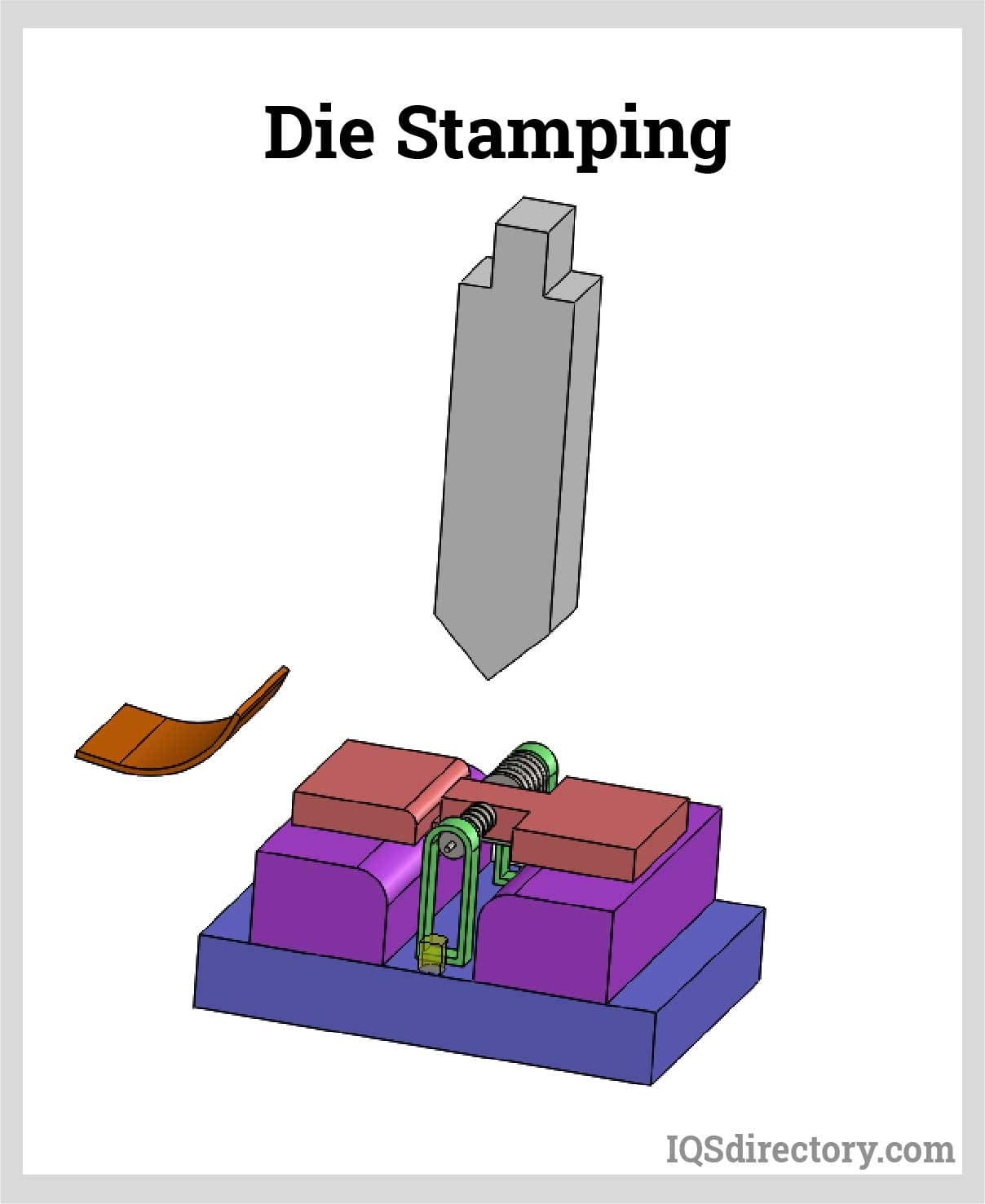

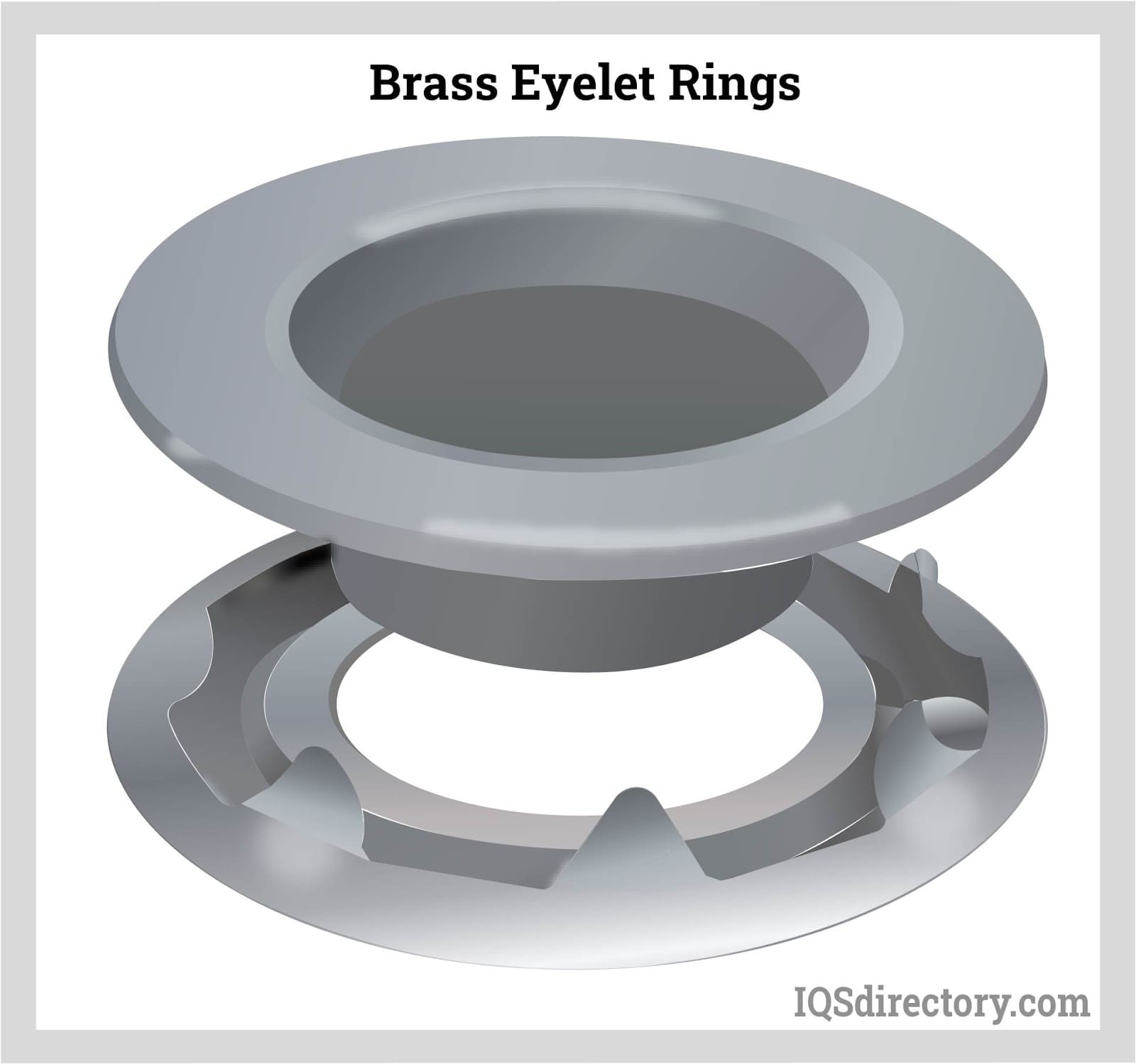

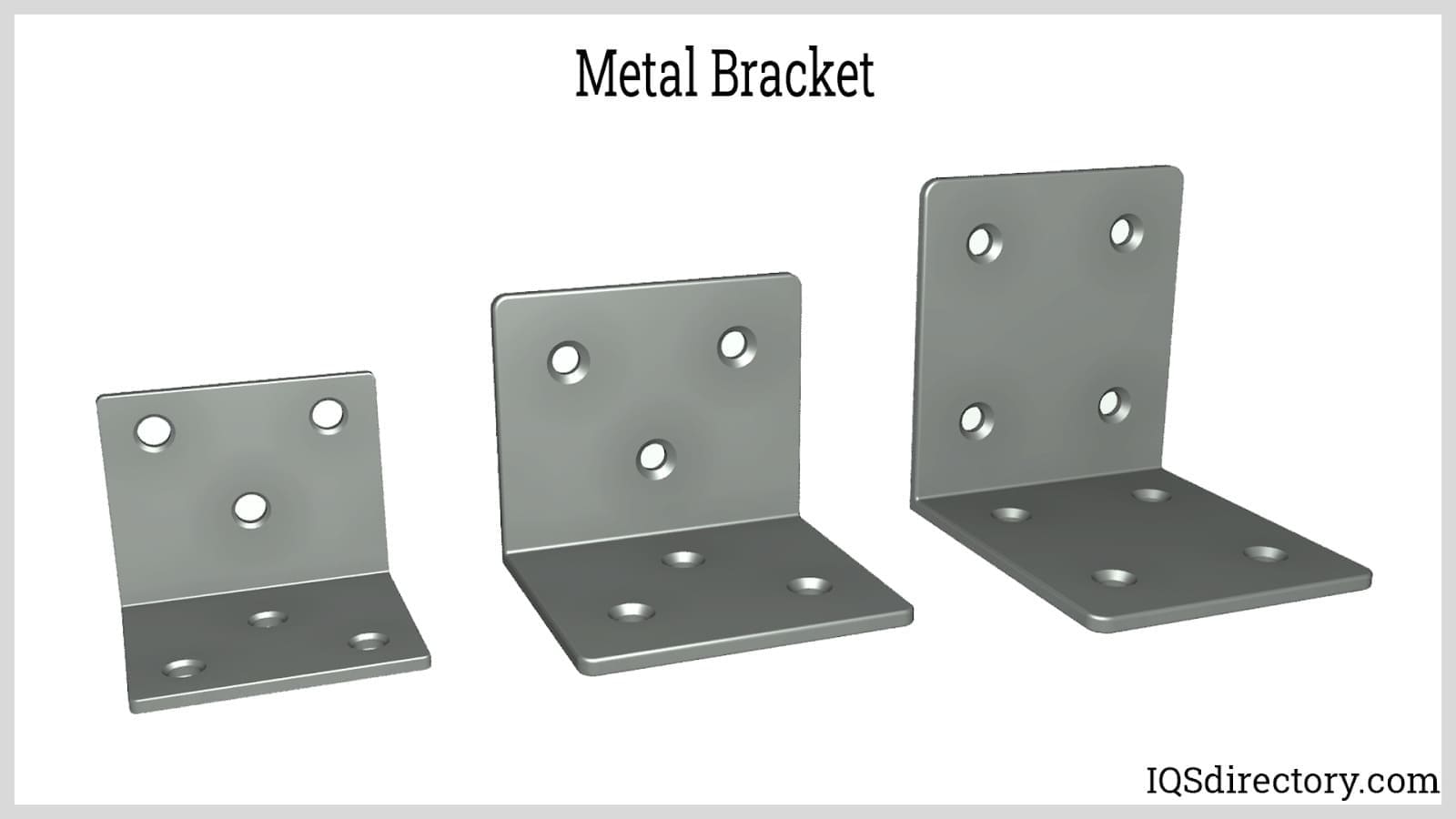

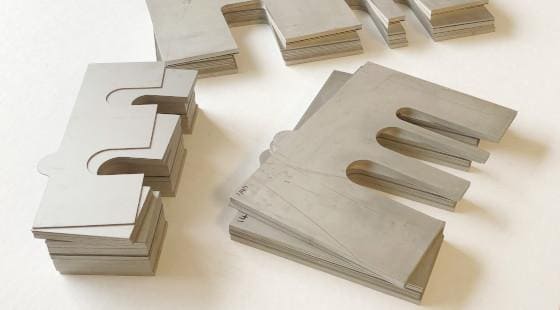

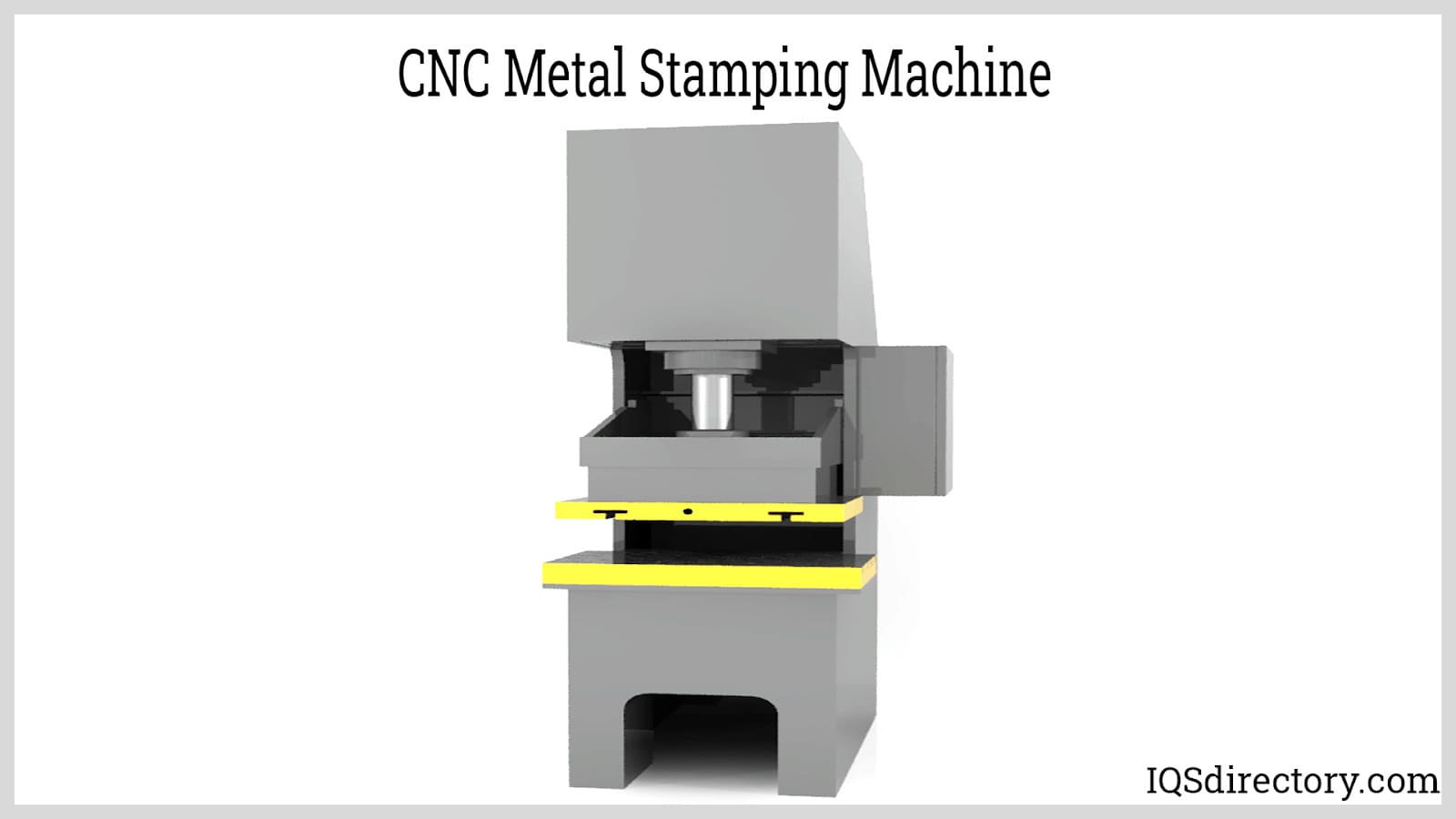

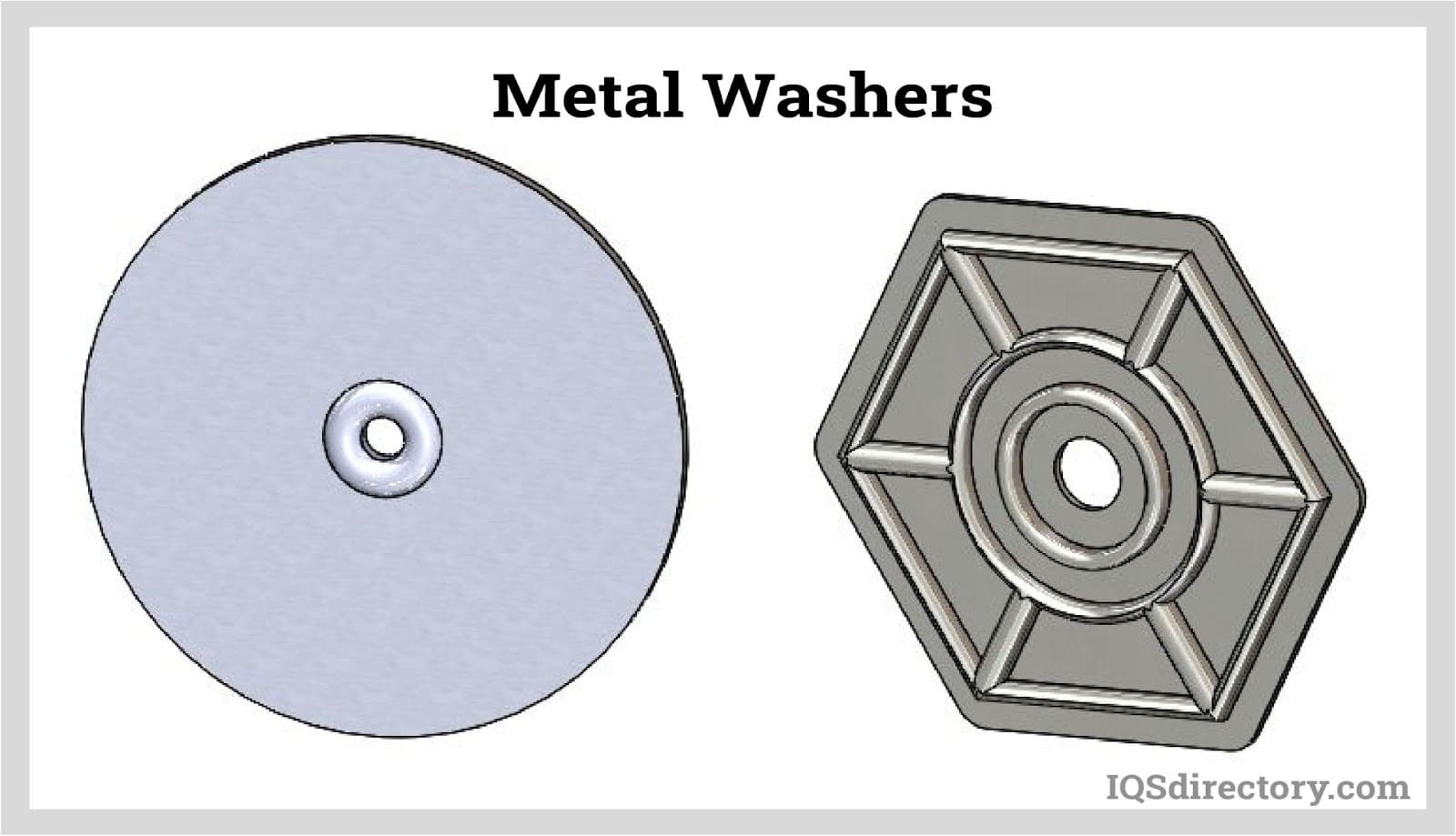

Grafton, WIKapco Metal Stamping is a leading company in the metal stamping industry, renowned for our expertise, precision, and commitment to delivering exceptional products and services. As a trusted manufacturer, we specialize in providing a comprehensive range of metal stamping solutions to a diverse range of industries. At Kapco Metal Stamping, we offer a wide variety of metal stamping products tailored to meet the specific needs of our customers. Our state-of-the-art facilities house a wide range of presses, allowing us to handle various materials, thicknesses, and complexities. We excel in manufacturing high-quality metal stampings, including brackets, connectors, clips, terminals, fasteners, and intricate components for industries such as automotive, aerospace, electronics, and more. With our advanced capabilities, we can produce metal stampings in different shapes, sizes, and materials, ensuring that we can fulfill the unique requirements of each client. Our commitment to delivering exceptional products is supported by our comprehensive suite of services. We work closely with our clients throughout the entire metal stamping process, providing design and engineering assistance to optimize component manufacturability, functionality, and cost-effectiveness. Our experienced team of engineers and technicians leverages their expertise to provide valuable insights and recommendations, ensuring that our customers' designs are translated into high-quality metal stampings. At Kapco Metal Stamping, we pride ourselves on our capabilities to handle diverse projects, from small-volume production to large-scale orders. Our facilities are equipped with advanced technology and efficient manufacturing processes, enabling us to meet tight deadlines and deliver superior products in a timely manner. We understand the importance of precision and consistency in metal stamping, and therefore, we have implemented rigorous quality control measures throughout our production process to ensure that each metal stamping meets or exceeds the highest industry standards. Moreover, at Kapco Metal Stamping, we understand the importance of staying at the forefront of the industry. We invest in research and development to continually enhance our capabilities and explore new technologies and materials. By staying updated on the latest trends and advancements in metal stamping, we can offer innovative solutions to our clients, helping them stay competitive in their respective markets. Our company culture is built on a foundation of excellence, integrity, and customer satisfaction. We prioritize open communication, collaboration, and long-term partnerships with our clients. Our dedicated customer service team ensures that our clients' needs are met, providing timely responses, technical assistance, and efficient order management. In summary, Kapco Metal Stamping is a trusted provider of metal stamping solutions, offering a comprehensive range of products and services. With our advanced capabilities, commitment to quality, and customer-focused approach, we are dedicated to meeting the unique requirements of each client. Whether it's complex components, precise tolerances, or large-scale production, we have the expertise and resources to deliver exceptional metal stampings that exceed expectations and drive our customers' success.

Broaching

Broaching CNC Machining

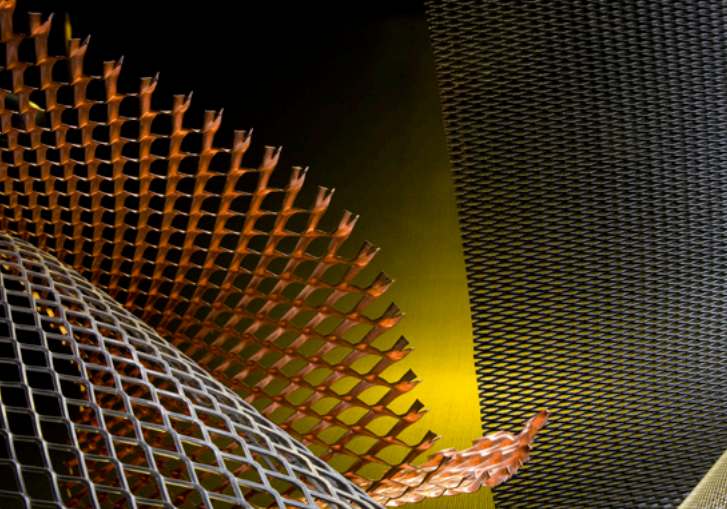

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

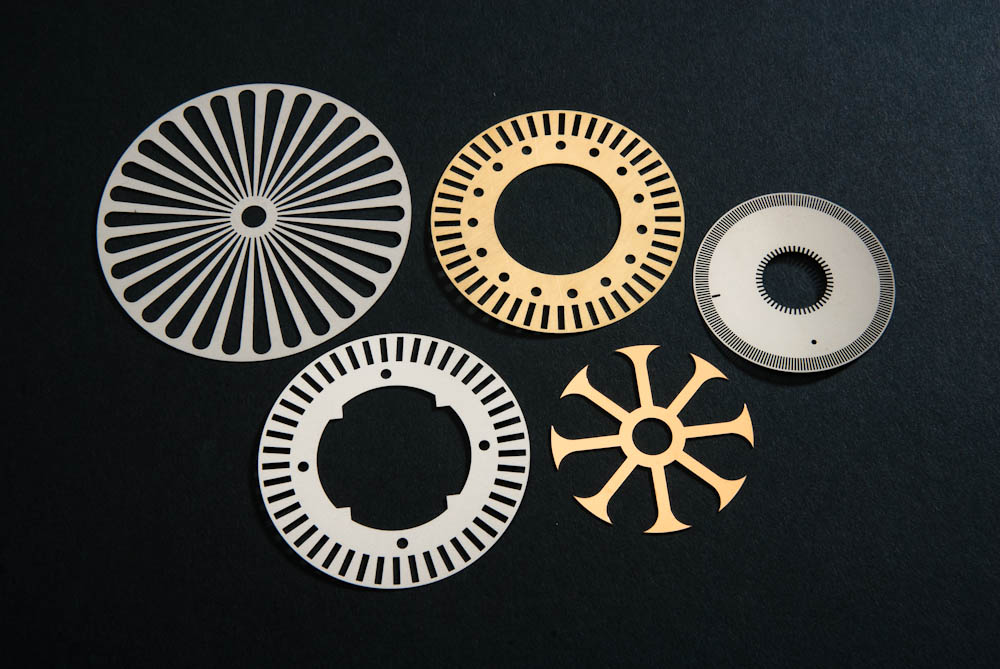

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

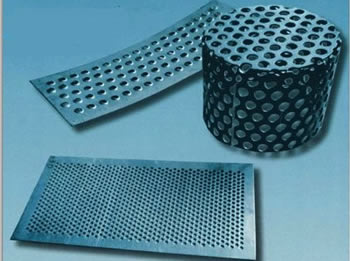

Metal Fabrication Perforated Metals

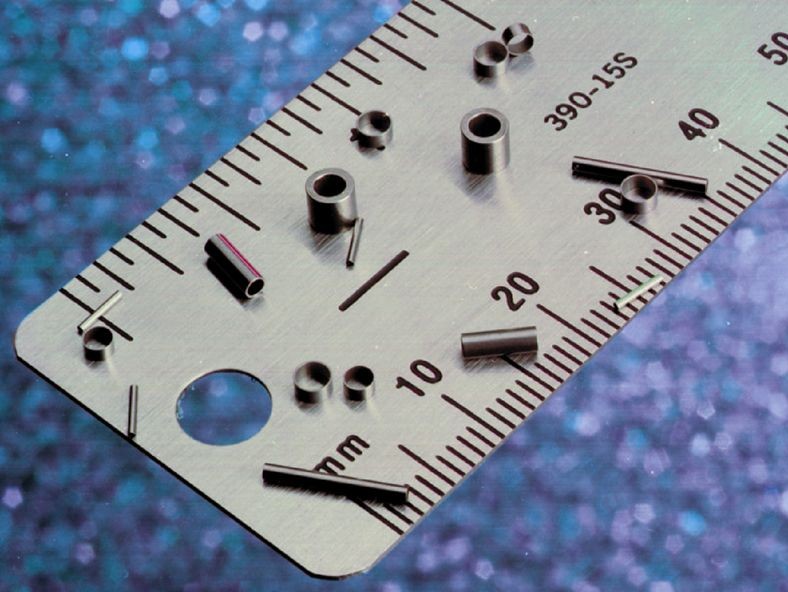

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

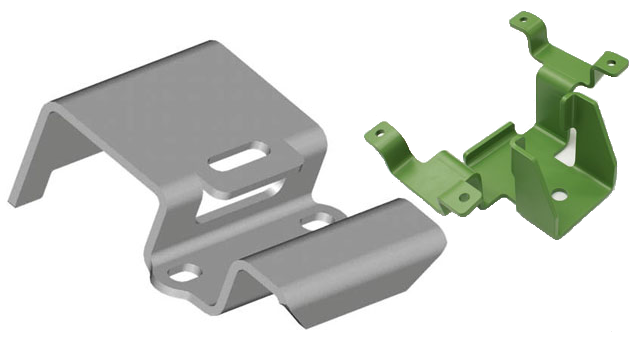

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services