Moore Tool and Die

Moore Tool and DieRequest A Quote

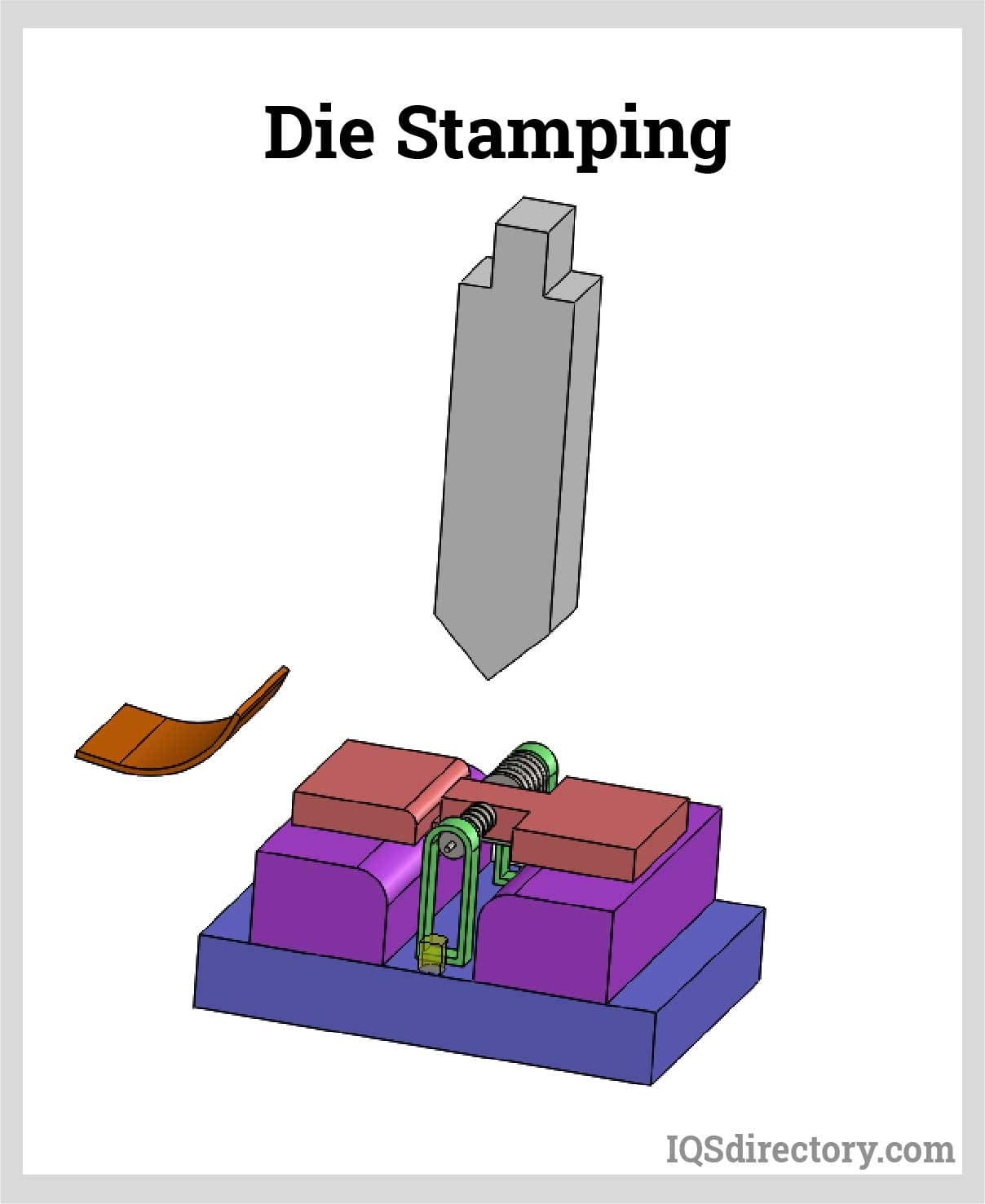

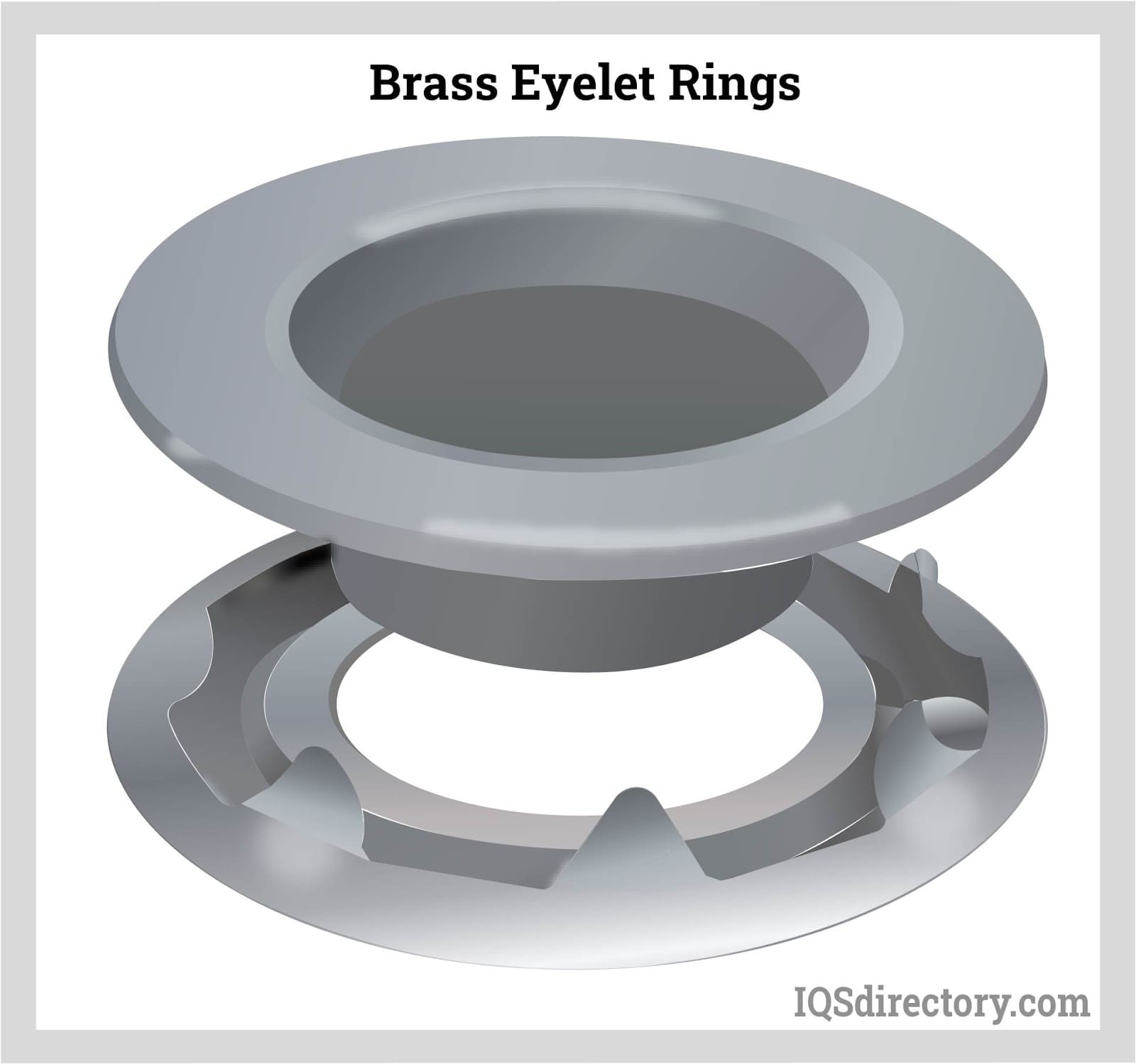

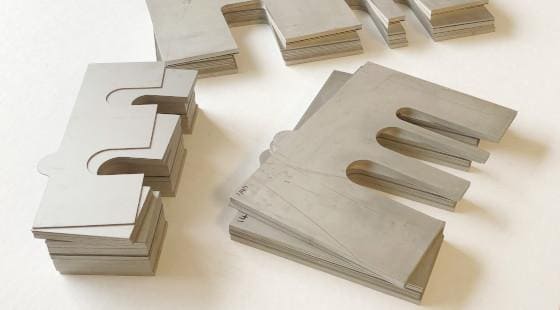

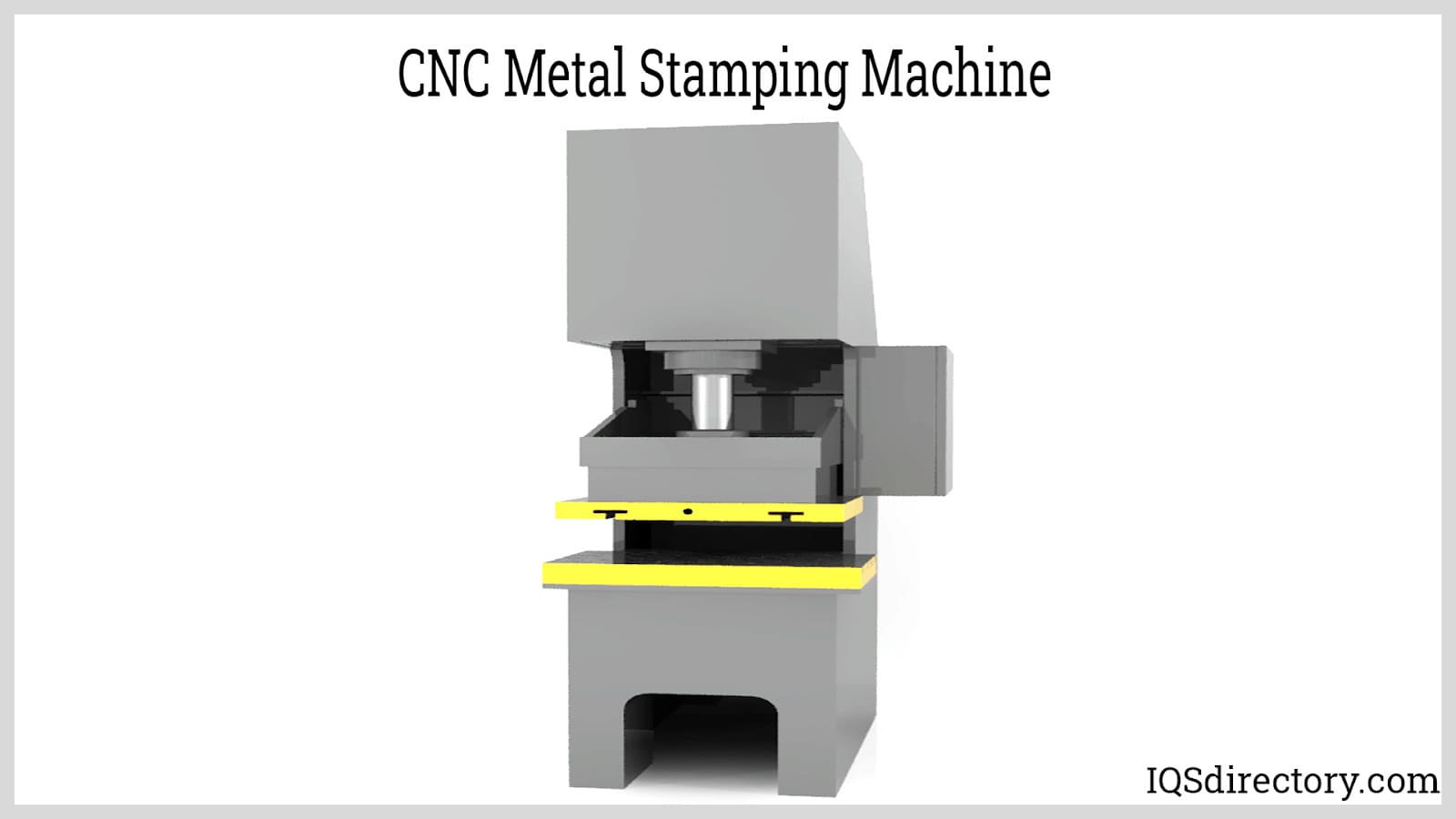

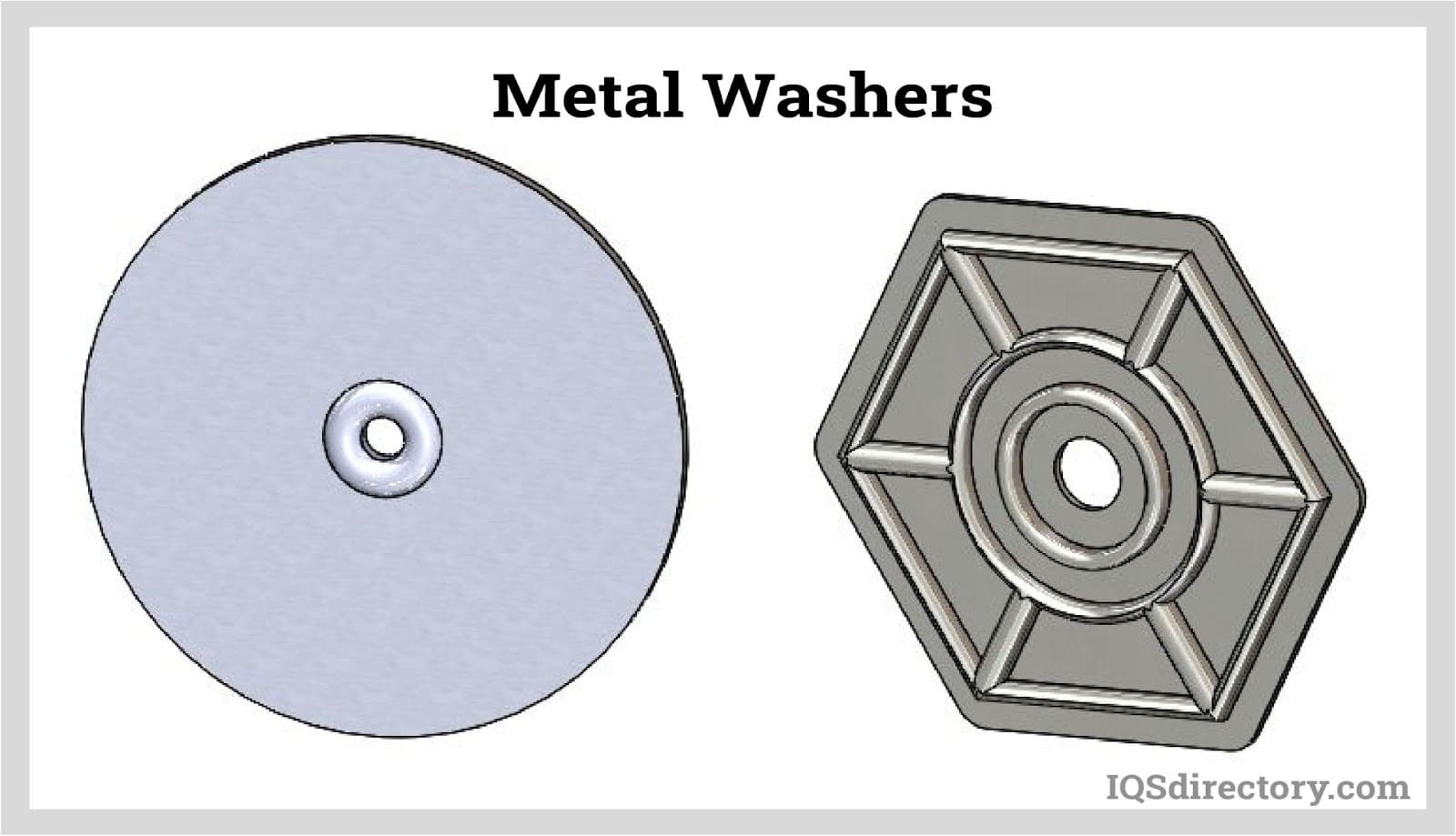

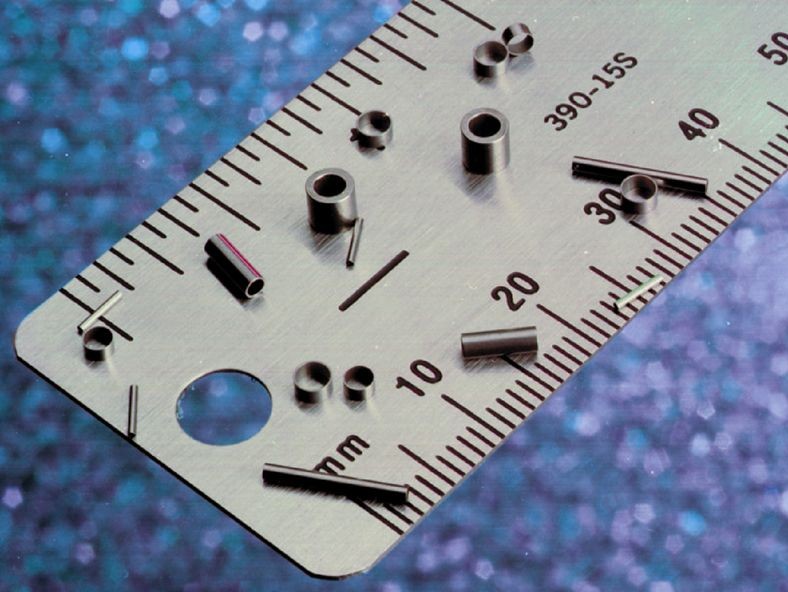

Gilbert, ArizonaHeadquartered in Gilbert, Arizona, Moore Tool and Die stands as an emblem of ingenuity and precision. With a legacy of excellence, they have carved a distinct niche in the industry as a paragon of quality and innovation. Offering a comprehensive suite of services, Moore Tool and Die is a one-stop destination for a multitude of manufacturing needs. Central to their expertise lies their Metal Stamping services, a realm where they shine as luminaries of precision. Moore Tool and Die's mastery over Metal Forming and Stamping Tools is unparalleled, with a specialization in crafting high-volume, compact precision metal components. This proficiency has positioned them as trailblazers in the art of transforming raw materials into intricate, reliable components that power industries far and wide. The heart of their operations extends to Tooling Repair and Service, where their skilled technicians breathe life into worn-out tools, optimizing their functionality and extending their lifespans. The Engineering Services offered by Moore Tool and Die harness the brilliance of their experienced professionals to devise innovative solutions that cater to diverse client needs. The core of their operation revolves around Tool & Die Design and Build, a realm where their meticulous craftsmanship takes center stage. This extends seamlessly into Metal Prototyping & Short Run Manufacturing, where Moore Tool and Die's agile production capabilities bring concepts to life swiftly and with unwavering precision. Precision Component Manufacturing is another forte where Moore Tool and Die excels, utilizing state-of-the-art technology to fabricate components to the highest standards. With a keen eye for Product Development, they seamlessly navigate the path from conceptualization to the final product, ensuring every detail is perfected. In the realm of Body-in-White (BIW) Engineering and Manufacturing, Moore Tool and Die showcases their proficiency in crafting intricate components that form the backbone of complex automotive assemblies. Meanwhile, their Custom Flat Spring Parts underscore their versatility, catering to a wide range of industries and applications. With a relentless commitment to excellence, Moore Tool and Die's Metal Stamping services epitomize their dedication to crafting components that drive industries forward. Their capability to design, build, and service metal forming and stamping tools, combined with their specialization in high-volume compact precision metal components, underscores their leadership in the field. As a beacon of innovation and precision, Moore Tool and Die continues to redefine industry standards while providing cutting-edge solutions that stand the test of time.

Broaching

Broaching CNC Machining

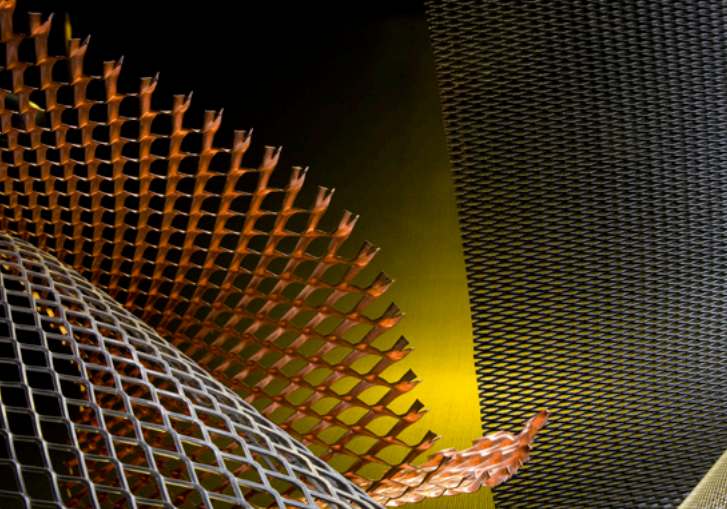

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

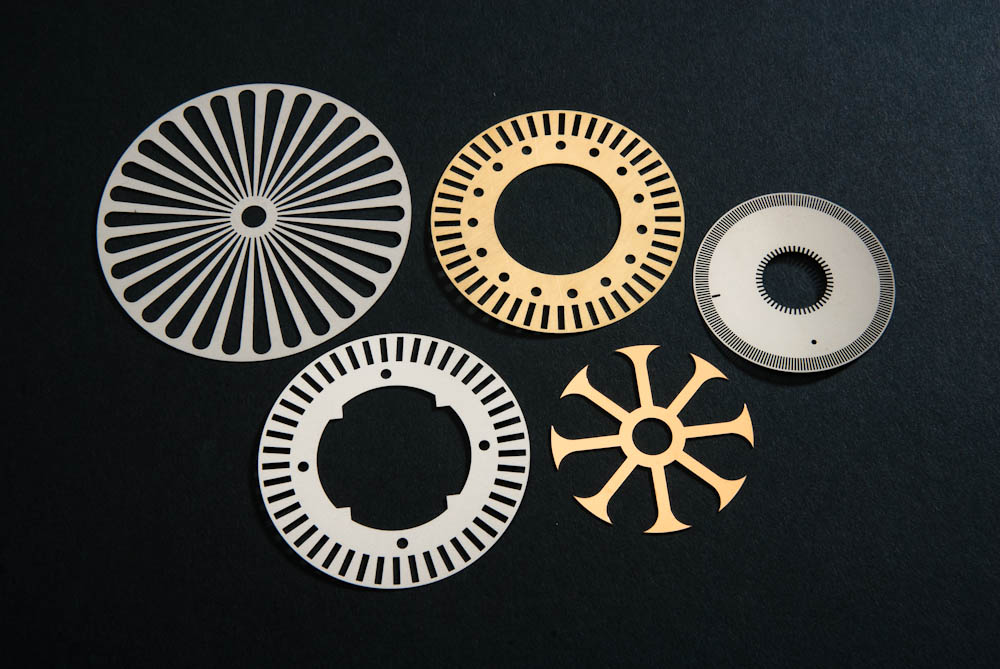

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

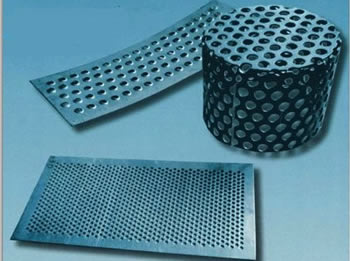

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

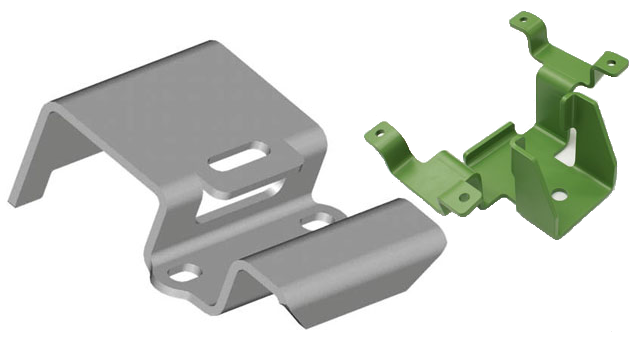

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services